2 月 . 13, 2025 19:47

Back to list

Traffic Trench Drain Grate China Manufacturing Metal Security Window Grates

White perforated metal sheets are revolutionizing architectural and industrial designs with their unique blend of aesthetics, functionality, and durability. As someone deeply embedded in the world of materials engineering and architectural design, my experience with these metal sheets has unveiled countless creative possibilities and practical applications that extend beyond traditional uses.

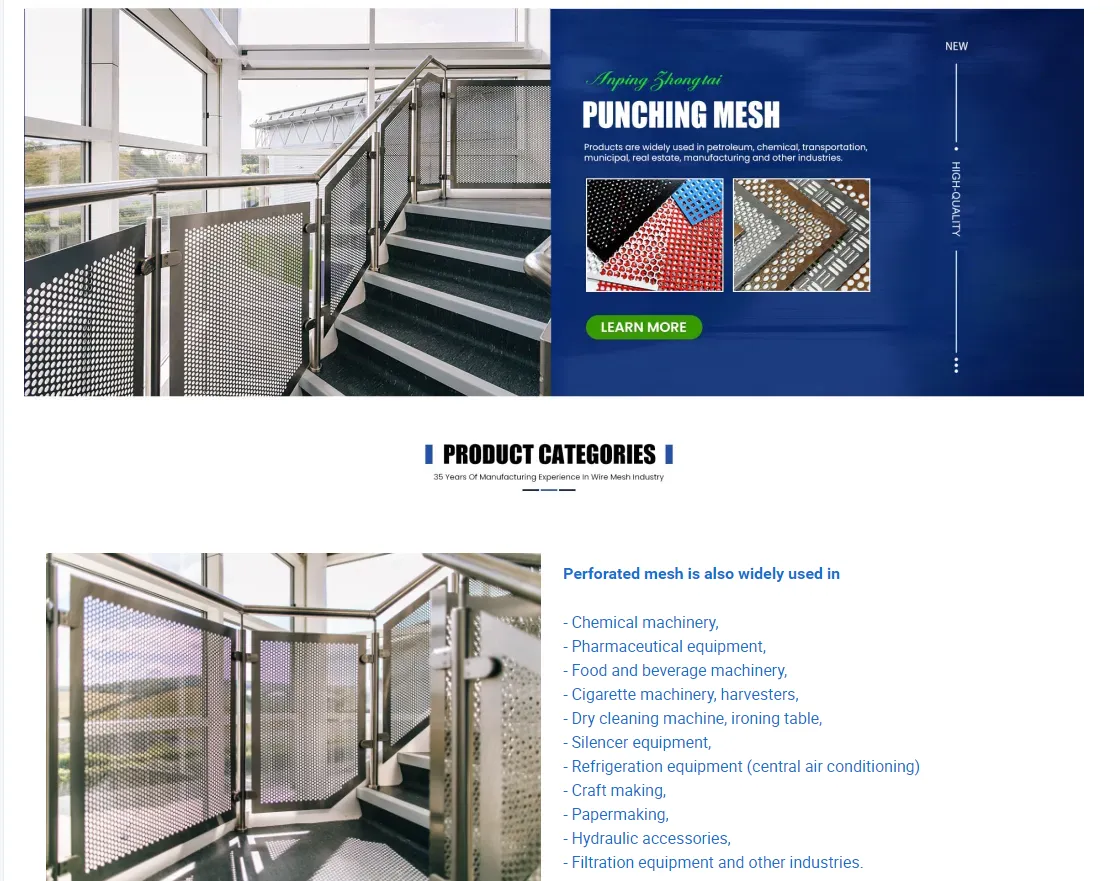

Trustworthiness is a key factor when selecting materials for critical projects. White perforated metal sheets instill confidence in both clients and contractors due to their proven performance in various applications. They have been tested extensively for strength, resilience, and safety. Furthermore, reputable manufacturers adhere to international standards of quality, ensuring that their products meet or exceed expectations. The technical specifications, such as hole size, pattern, and coating quality, are meticulously documented and available for client reference, reinforcing the reliability of these products. On a practical level, my personal experience with white perforated metal sheets has showcased their ease of installation. Their lightweight nature and the ability to be custom-fabricated to exact sizes and patterns make them highly adaptable to both new builds and renovations. They can be easily integrated with other building materials, providing seamless interface and connectivity, whether in terms of structural elements or aesthetic transitions. Ultimately, white perforated metal sheets are more than just a design solution; they are a testament to innovation in material science and design engineering. Their unique attributes offer superior benefits that cater to modern demands for functional, sustainable, and attractive building materials. For those seeking to push the boundaries of design or enhance the environmental performance of their projects, these sheets present an exemplary option that fuses elegance with practicality. By focusing on the expanse of applications, scientific rigor in creation, and verified durability, white perforated metal sheets emerge as indispensable in the toolkit of forward-thinking architects and designers. As industries continue to demand materials that not only meet technical specifications but also contribute positively to their surrounding ecosystem, these metal sheets are poised to remain at the forefront of material solutions for years to come.

Trustworthiness is a key factor when selecting materials for critical projects. White perforated metal sheets instill confidence in both clients and contractors due to their proven performance in various applications. They have been tested extensively for strength, resilience, and safety. Furthermore, reputable manufacturers adhere to international standards of quality, ensuring that their products meet or exceed expectations. The technical specifications, such as hole size, pattern, and coating quality, are meticulously documented and available for client reference, reinforcing the reliability of these products. On a practical level, my personal experience with white perforated metal sheets has showcased their ease of installation. Their lightweight nature and the ability to be custom-fabricated to exact sizes and patterns make them highly adaptable to both new builds and renovations. They can be easily integrated with other building materials, providing seamless interface and connectivity, whether in terms of structural elements or aesthetic transitions. Ultimately, white perforated metal sheets are more than just a design solution; they are a testament to innovation in material science and design engineering. Their unique attributes offer superior benefits that cater to modern demands for functional, sustainable, and attractive building materials. For those seeking to push the boundaries of design or enhance the environmental performance of their projects, these sheets present an exemplary option that fuses elegance with practicality. By focusing on the expanse of applications, scientific rigor in creation, and verified durability, white perforated metal sheets emerge as indispensable in the toolkit of forward-thinking architects and designers. As industries continue to demand materials that not only meet technical specifications but also contribute positively to their surrounding ecosystem, these metal sheets are poised to remain at the forefront of material solutions for years to come.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP