Expanded metal mesh is a versatile material that finds applications across a diverse range of industries. This adaptability stems from its unique manufacturing process, where a solid sheet of metal is simultaneously slit and stretched, forming a mesh with diamond-shaped openings. Here, we delve into the different types of expanded metal mesh, each offering distinct characteristics and suited for specific applications.

Expanded metal mesh is typically classified based on its pattern, size, and thickness. The standard expanded metal features a raised pattern that provides excellent grip and traction, ideal for walkways and industrial platforms where slip resistance is crucial. This type is also favored in construction projects for its structural reinforcement properties.

Flattened expanded metal, on the other hand, undergoes an additional flattening process to smooth out the raised sections. This results in a sleek, smooth surface better suited for applications requiring a refined finish, such as decorative architectural screens and partitions. It offers the aesthetic appeal of transparency while maintaining structural integrity.

Another variant, micro expanded metal, is characterized by its tiny openings that offer high precision and finer filtration capabilities. It is widely employed in advanced engineering applications, including aerospace and automotive industries, where weight reduction and maximum strength are imperative. Micro expanded metal is also a preferred material for intricate grilles and fine mesh filters.

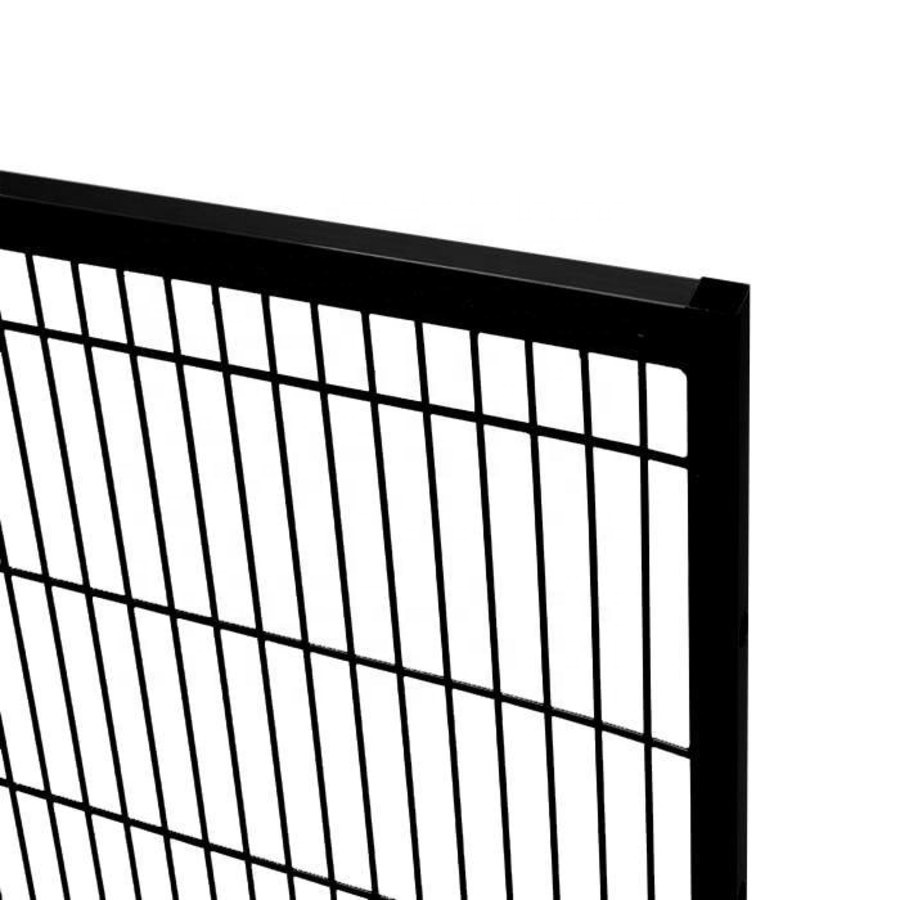

Heavy gauge expanded metal is designed to deliver superior strength and durability. It's most commonly used in security installations, such as fencing and gates, where robustness is paramount. With thicker strands and a denser mesh pattern, it can withstand high-impact forces, ensuring optimum protection and longevity.

types of expanded metal mesh

Specialty expanded metals have risen in popularity due to their tailored properties for specific environments. Some undergo surface treatments like galvanization or powder coating, enhancing their resistance to elements like corrosion and UV radiation. These treated meshes are perfect for coastal or chemically aggressive environments.

From a manufacturing perspective, materials such as steel, aluminum, and stainless steel are frequently used for expanded metal mesh due to their inherent properties. Steel meshes are praised for their strength and affordability, while aluminum is preferred when lightweight solutions are required. Stainless steel meshes are chosen for applications requiring excellent corrosion resistance and hygiene, such as in food processing and medical facilities.

In practical applications, selecting the appropriate type of expanded metal mesh hinges on understanding the specific requirements of the project. This material's capacity to provide tailored solutions is why it remains an indispensable component in sectors like architecture, transportation, security, and more.

In conclusion, navigating the wide range of expanded metal mesh types requires a keen understanding of each variant’s inherent properties and best-fit applications. As industries continue to seek innovative solutions, the demand for suitable expanded metal meshes is only expected to grow.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.