When considering the purchase of expanded metal sheets, it's essential to understand not only the product itself but also the substantial benefits it can bring to a range of applications. As an industry expert with years of hands-on experience in the field, I aim to share insights that will enhance your understanding and decision-making process regarding expanded metal sheets.

Expanded metal sheets are produced using a specific process where metal is simultaneously slit and stretched to create a mesh-like sheet. This process doesn't just retain the metal’s inherent strength but enhances it by increasing the load-bearing properties. The sheets come in a variety of materials, including aluminum, stainless steel, and carbon steel, each serving different needs based on their unique properties such as weight, durability, and resistance to corrosion.

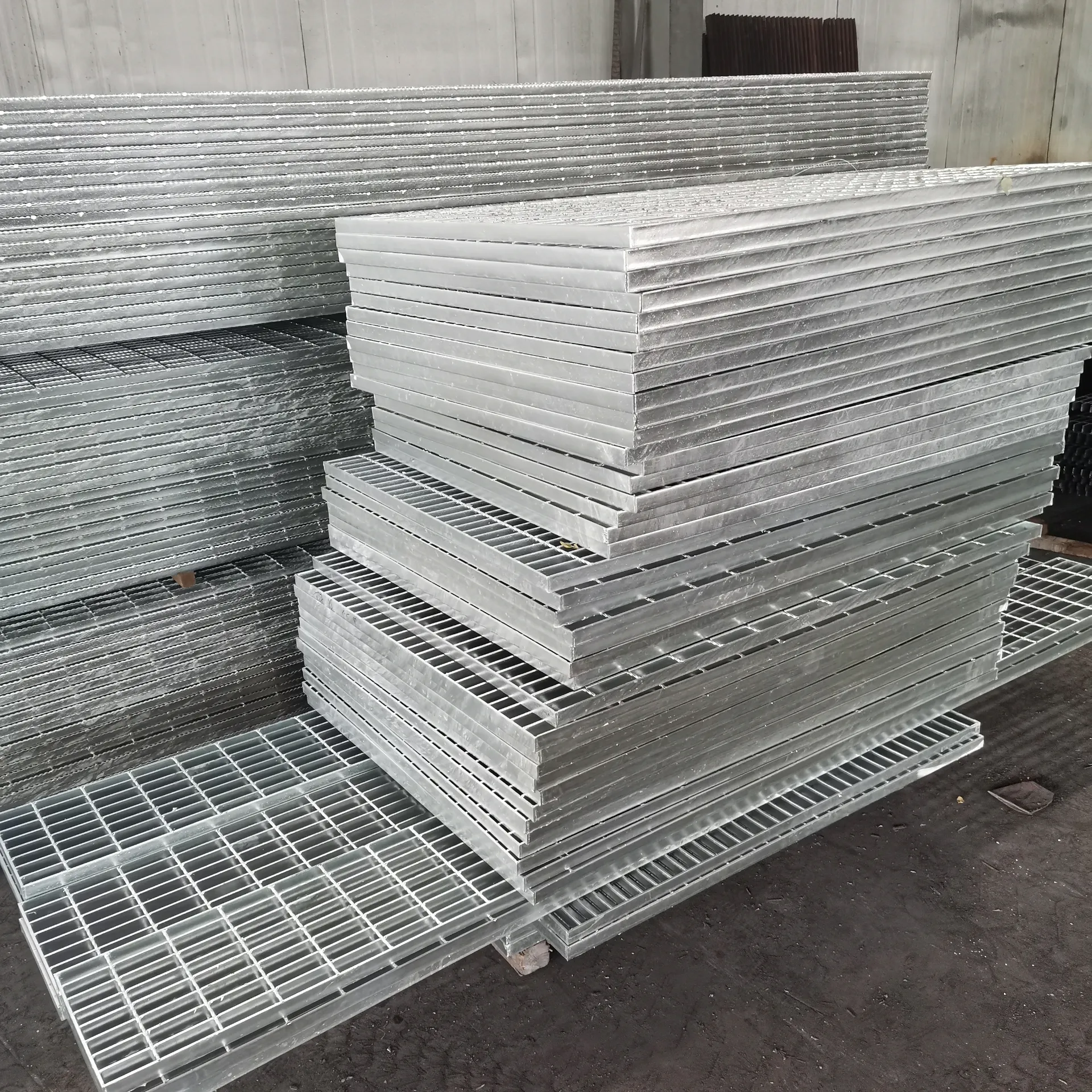

In construction, expanded metal sheets are lauded for their versatility and structural soundness. These sheets are used for fencing, walkways, and support structures, providing an optimal balance between weight and strength. This makes them particularly appealing in projects where load-bearing strength without excessive weight is needed. A recent project I consulted for involved using aluminum expanded sheets for a lightweight yet durable pedestrian bridge, significantly reducing costs without compromising structural integrity.

Given their non-skid properties, these metal sheets are also extensively used in safety applications. The inherent design of an expanded metal sheet ensures maximum gripping surface, making it ideal for stair treads and ramps. This attribute enhances safety, especially in environments prone to moisture and thus susceptible to slipping hazards.

expanded metal sheets for sale

In the realm of design and architecture, expanded metal sheets are gaining popularity for their aesthetic appeal. Their ability to allow light passage while providing privacy makes them a favorable choice for modern architectural designs. Recently, I worked with a client who used stainless steel expanded sheets for an office facade, achieving a contemporary look while optimizing light filtration into the workspace.

From an industrial standpoint, expanded metal’s durability and versatility are unmatched. It's used in filtration systems, where the precise apertures are crucial for controlling airflow and particulate filtration. The sheets’ ability to withstand harsh environmental conditions makes them suitable for outdoor and industrial applications, where they ensure longevity and high performance.

For those considering business operations involving expanded metal sheets, finding a trustworthy supplier is paramount. Reputation, quality assurance, and a comprehensive product range are critical factors. A reliable provider not only offers high-quality products but also provides industry insights, customization options, and post-purchase support.

In conclusion, the purchase of expanded metal sheets should be guided by a clear understanding of the material's properties and the specific needs of your application. Leveraging expertise from a reputable supplier, combined with informed decision-making, ensures that you maximize the potential of expanded metal sheets in your projects. Whether for structural, aesthetic, or safety applications, these sheets offer a robust, versatile solution that stands the test of time and conditions.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.