1 月 . 29, 2025 03:59

Back to list

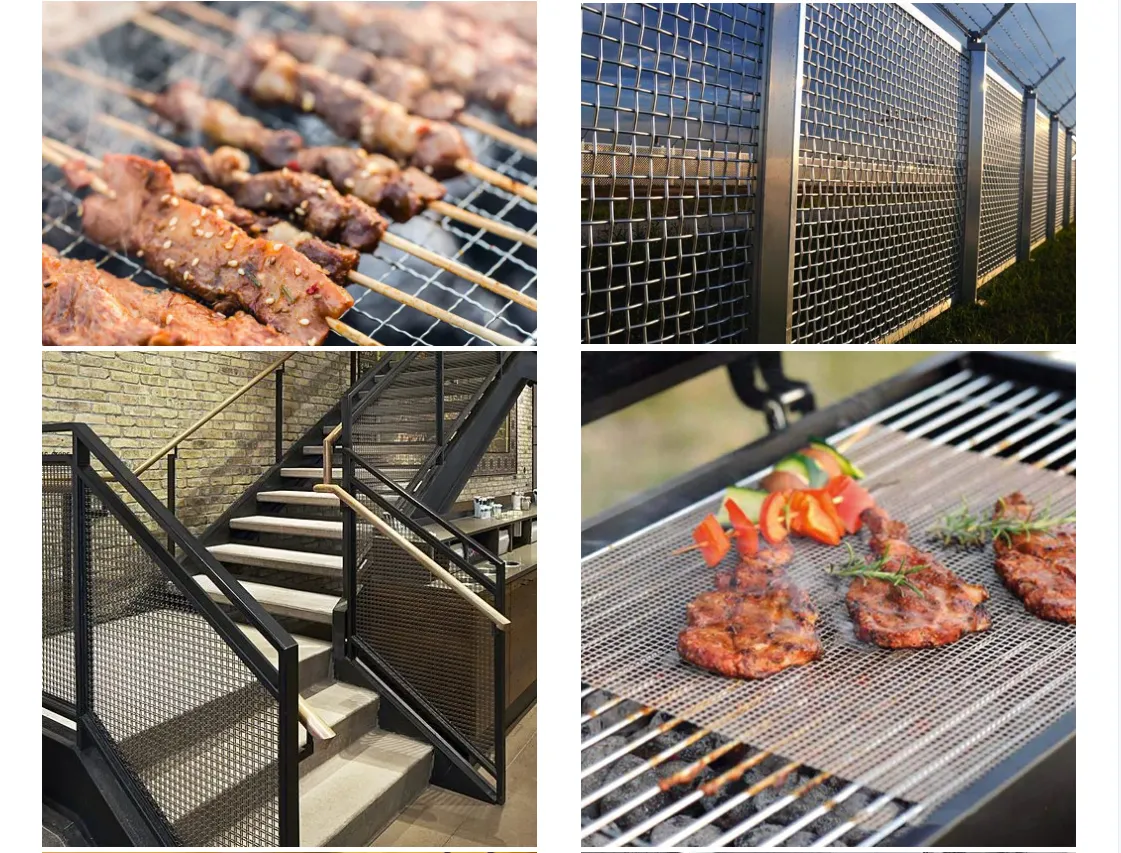

trench cover steel grating

Navigating the intricate landscape of industrial applications demands materials that are both robust and versatile. Trench cover steel grating emerges as a leader in providing the needed support and safety in various environments. This article delves into the unique composition and practical advantages of steel gratings when employed as trench covers, emphasizing their durability and unparalleled utility.

Furthermore, authority in the field of steel grating is exhibited through rigorous testing and compliance with international standards such as ANSI/NAAMM and BS EN ISO. Such certifications assure users of the quality and safety of the products. Projects requiring trench cover solutions can confidently rely on verified suppliers who uphold these standards, ensuring that safety and performance are never compromised. The trustworthiness of trench cover steel gratings is reinforced by their long-term track record and the confidence they inspire in contractors and engineers alike. Their installation is straightforward, and they require minimal maintenance, which significantly lowers life-cycle costs. Testimonials from businesses across industries—from wastewater treatment plants to shipping ports—affirm the reliability of steel grating trench covers in maintaining operational integrity. Innovative applications of steel grating extend its utility even further. For instance, companies are now embedding smart sensors in the trench covers. These sensors can provide real-time data on load stress and environmental conditions, enabling predictive maintenance and further safeguarding infrastructure. Such technological integration demonstrates the adaptability of steel gratings to future urban development needs, making them a cornerstone for smart city projects. In conclusion, trench cover steel gratings are not merely functional components; they are engineered with precision, backed by extensive industry knowledge, and built to last. Their excellent performance across different conditions and commitment to high standards ensures that they remain the preferred choice for modern infrastructure needs. Whether dealing with the relentless demands of traffic or the challenges posed by environmental factors, trench cover steel gratings stand out, offering a reliable, long-lasting solution for infrastructure development worldwide.

Furthermore, authority in the field of steel grating is exhibited through rigorous testing and compliance with international standards such as ANSI/NAAMM and BS EN ISO. Such certifications assure users of the quality and safety of the products. Projects requiring trench cover solutions can confidently rely on verified suppliers who uphold these standards, ensuring that safety and performance are never compromised. The trustworthiness of trench cover steel gratings is reinforced by their long-term track record and the confidence they inspire in contractors and engineers alike. Their installation is straightforward, and they require minimal maintenance, which significantly lowers life-cycle costs. Testimonials from businesses across industries—from wastewater treatment plants to shipping ports—affirm the reliability of steel grating trench covers in maintaining operational integrity. Innovative applications of steel grating extend its utility even further. For instance, companies are now embedding smart sensors in the trench covers. These sensors can provide real-time data on load stress and environmental conditions, enabling predictive maintenance and further safeguarding infrastructure. Such technological integration demonstrates the adaptability of steel gratings to future urban development needs, making them a cornerstone for smart city projects. In conclusion, trench cover steel gratings are not merely functional components; they are engineered with precision, backed by extensive industry knowledge, and built to last. Their excellent performance across different conditions and commitment to high standards ensures that they remain the preferred choice for modern infrastructure needs. Whether dealing with the relentless demands of traffic or the challenges posed by environmental factors, trench cover steel gratings stand out, offering a reliable, long-lasting solution for infrastructure development worldwide.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP