1 月 . 29, 2025 03:33

Back to list

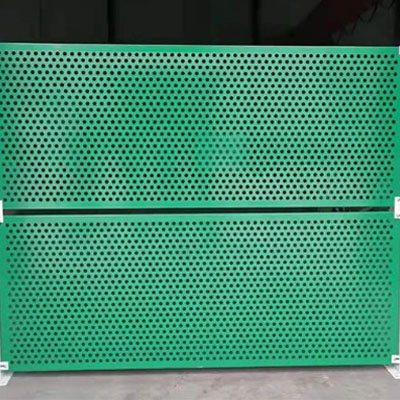

compound steel grating

Compound steel grating is revolutionizing the way industries approach safety and durability in their infrastructures. As someone who has delved deeply into the nuances of steel fabrications and applications, I'll guide you through the myriad benefits and features of this exceptional product, which stands out as a leader in the realm of industrial materials.

From a technical standpoint, the installation of compound steel grating is a seamless process. Its lightweight nature contrasts with its strength, allowing for easier handling and installation, thereby reducing labor costs and downtime. This efficiency in installation also contributes to a reduction in overall project timelines, an advantage that every project manager values. Trustworthiness is another critical aspect when selecting industrial materials, and compound steel grating offers peace of mind through its compliance with rigorous safety standards and regulations. Manufacturers often undergo stringent quality checks and testing phases, ensuring that the final product delivered is not only robust but also trustworthy for prolonged use in challenging settings. The environmental impact is minimized with compound steel grating as it is recyclable and made from sustainable materials, aligning with global trends towards greener practices. Companies seeking to enhance their ecological footprint or adhere to strict environmental regulations will find this aspect particularly advantageous. In conclusion, compound steel grating represents a sophisticated blend of strength, safety, and adaptability, making it an indispensable asset in various industrial applications. Its unique features cater to the demanding environments of modern industries, while its customizable options and straightforward installation make it a practical solution for projects worldwide. As an authority in the field, I have witnessed firsthand how this product transforms operational efficiency and enhances safety, attesting to the indispensable value it provides.

From a technical standpoint, the installation of compound steel grating is a seamless process. Its lightweight nature contrasts with its strength, allowing for easier handling and installation, thereby reducing labor costs and downtime. This efficiency in installation also contributes to a reduction in overall project timelines, an advantage that every project manager values. Trustworthiness is another critical aspect when selecting industrial materials, and compound steel grating offers peace of mind through its compliance with rigorous safety standards and regulations. Manufacturers often undergo stringent quality checks and testing phases, ensuring that the final product delivered is not only robust but also trustworthy for prolonged use in challenging settings. The environmental impact is minimized with compound steel grating as it is recyclable and made from sustainable materials, aligning with global trends towards greener practices. Companies seeking to enhance their ecological footprint or adhere to strict environmental regulations will find this aspect particularly advantageous. In conclusion, compound steel grating represents a sophisticated blend of strength, safety, and adaptability, making it an indispensable asset in various industrial applications. Its unique features cater to the demanding environments of modern industries, while its customizable options and straightforward installation make it a practical solution for projects worldwide. As an authority in the field, I have witnessed firsthand how this product transforms operational efficiency and enhances safety, attesting to the indispensable value it provides.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP