2 月 . 11, 2025 06:18

Back to list

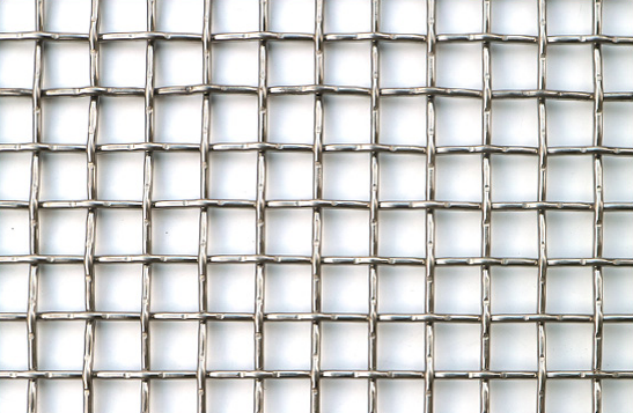

stainless perforated metal

Stainless perforated metal is a versatile material known for its strength, durability, and aesthetic appeal. This robust material has become a staple in various industries, offering solutions that exceed the expectations of architects, designers, and engineers worldwide. Whether utilized in industrial applications or employed to enhance architectural designs, stainless perforated metal stands as an exemplar of modern engineering and design excellence.

Moreover, the medical industry benefits from stainless perforated metal due to its non-porous surface, which can be easily sterilized. It is frequently utilized in the fabrication of medical devices, hospital fixtures, and laboratory equipment. These applications demand the highest hygiene standards, and stainless perforated metal consistently meets these needs while providing the necessary durability and precision. Stainless perforated metal also plays a crucial role in transportation infrastructure. Its lightweight yet sturdy nature makes it ideal for constructing barriers, soundproofing panels, and even components of public transportation vehicles. These applications leverage the metal’s noise-reducing capabilities and its ability to withstand harsh weather conditions, vibrations, and impact—ensuring safety and comfort for passengers and operators alike. The automotive industry is another sector where stainless perforated metal is making a significant impact. Car manufacturers use it in grilles and exhaust systems, where it contributes to aesthetics as well as performance. The ability to withstand heat and resist corrosion ensures long-lasting functionality, while the customizable patterns add a unique visual element to vehicle design. As technology advances, the potential applications for stainless perforated metal continue to expand. Engineers and material scientists are discovering new ways to enhance its properties, such as improving acoustic reduction capabilities or developing coatings that further minimize maintenance needs. These innovations promise to increase the material's appeal across more varied and demanding applications, ensuring its relevance in the years to come. In conclusion, stainless perforated metal exemplifies the principles of modern engineering by offering versatile, sustainable, and aesthetically pleasing solutions across a broad spectrum of industries. Its unique properties support numerous uses, from enhancing architecture's visual and environmental effectiveness to providing reliable components in industrial machinery and infrastructure. By incorporating stainless perforated metal into projects, professionals are choosing a material that not only meets rigorous technical standards but also aligns with contemporary design and environmental ethics. This makes it a crucial player in meeting the dynamic needs of modern society, reaffirming its status as a material of the present and the future.

Moreover, the medical industry benefits from stainless perforated metal due to its non-porous surface, which can be easily sterilized. It is frequently utilized in the fabrication of medical devices, hospital fixtures, and laboratory equipment. These applications demand the highest hygiene standards, and stainless perforated metal consistently meets these needs while providing the necessary durability and precision. Stainless perforated metal also plays a crucial role in transportation infrastructure. Its lightweight yet sturdy nature makes it ideal for constructing barriers, soundproofing panels, and even components of public transportation vehicles. These applications leverage the metal’s noise-reducing capabilities and its ability to withstand harsh weather conditions, vibrations, and impact—ensuring safety and comfort for passengers and operators alike. The automotive industry is another sector where stainless perforated metal is making a significant impact. Car manufacturers use it in grilles and exhaust systems, where it contributes to aesthetics as well as performance. The ability to withstand heat and resist corrosion ensures long-lasting functionality, while the customizable patterns add a unique visual element to vehicle design. As technology advances, the potential applications for stainless perforated metal continue to expand. Engineers and material scientists are discovering new ways to enhance its properties, such as improving acoustic reduction capabilities or developing coatings that further minimize maintenance needs. These innovations promise to increase the material's appeal across more varied and demanding applications, ensuring its relevance in the years to come. In conclusion, stainless perforated metal exemplifies the principles of modern engineering by offering versatile, sustainable, and aesthetically pleasing solutions across a broad spectrum of industries. Its unique properties support numerous uses, from enhancing architecture's visual and environmental effectiveness to providing reliable components in industrial machinery and infrastructure. By incorporating stainless perforated metal into projects, professionals are choosing a material that not only meets rigorous technical standards but also aligns with contemporary design and environmental ethics. This makes it a crucial player in meeting the dynamic needs of modern society, reaffirming its status as a material of the present and the future.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP