2 月 . 11, 2025 05:42

Back to list

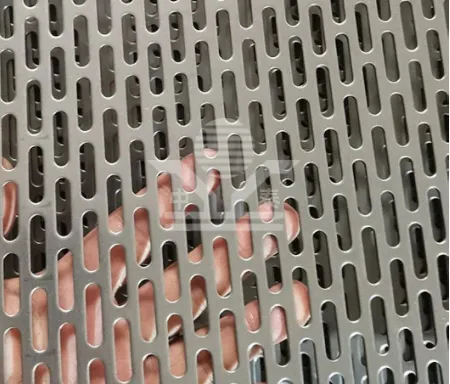

stainless perforated sheet

Stainless perforated sheets have transformed from mere industrial applications to essential components across various sectors including architecture, food processing, and automotive industries. Their versatility, durability, and aesthetic appeal make them a preferred choice beyond traditional applications, granting innovative solutions to a myriad of modern-day challenges.

The food processing sector values stainless perforated sheets for their hygiene and safety standards. The non-porous nature of stainless steel makes it an ideal choice for environments demanding strict sanitation controls. These sheets are commonly used in equipment such as sieves, filters, and conveyors. Their ability to withstand rigorous cleaning and sanitization processes without degrading ensures compliance with health regulations. Furthermore, the customizable perforations facilitate the separation and filtration processes, enhancing efficiency in food production. Stainless perforated sheets also play a critical role in sound management. In environments where noise control is paramount, such as in office layouts, theaters, and industrial plants, these sheets serve as effective acoustic panels. The strategic distribution of holes allows sound waves to dissipate effectively, reducing noise levels and improving acoustic quality. Their dual purpose as aesthetic and functional elements makes them valuable in designing spaces with optimal auditory environments. The expertise in manufacturing stainless perforated sheets involves precise engineering and state-of-the-art technology. Advances in laser cutting and automated punching techniques have expanded the potential for tailored designs and intricate patterns, pushing the boundaries of application possibilities. Leading manufacturers maintain stringent quality control measures ensuring product integrity and performance meet industry standards. Trust in stainless perforated sheets continues to grow as industries experience firsthand the multitude of benefits they offer. Their unmatched combination of aesthetic, functional, and long-lasting qualities confirm their standing as indispensable materials in modern construction and manufacturing. Companies seeking sustainable and innovative solutions regard stainless perforated sheets as valuable assets to improve efficiency, reduce environmental impact, and enhance the overall quality of their products and services.

The food processing sector values stainless perforated sheets for their hygiene and safety standards. The non-porous nature of stainless steel makes it an ideal choice for environments demanding strict sanitation controls. These sheets are commonly used in equipment such as sieves, filters, and conveyors. Their ability to withstand rigorous cleaning and sanitization processes without degrading ensures compliance with health regulations. Furthermore, the customizable perforations facilitate the separation and filtration processes, enhancing efficiency in food production. Stainless perforated sheets also play a critical role in sound management. In environments where noise control is paramount, such as in office layouts, theaters, and industrial plants, these sheets serve as effective acoustic panels. The strategic distribution of holes allows sound waves to dissipate effectively, reducing noise levels and improving acoustic quality. Their dual purpose as aesthetic and functional elements makes them valuable in designing spaces with optimal auditory environments. The expertise in manufacturing stainless perforated sheets involves precise engineering and state-of-the-art technology. Advances in laser cutting and automated punching techniques have expanded the potential for tailored designs and intricate patterns, pushing the boundaries of application possibilities. Leading manufacturers maintain stringent quality control measures ensuring product integrity and performance meet industry standards. Trust in stainless perforated sheets continues to grow as industries experience firsthand the multitude of benefits they offer. Their unmatched combination of aesthetic, functional, and long-lasting qualities confirm their standing as indispensable materials in modern construction and manufacturing. Companies seeking sustainable and innovative solutions regard stainless perforated sheets as valuable assets to improve efficiency, reduce environmental impact, and enhance the overall quality of their products and services.

Latest news

-

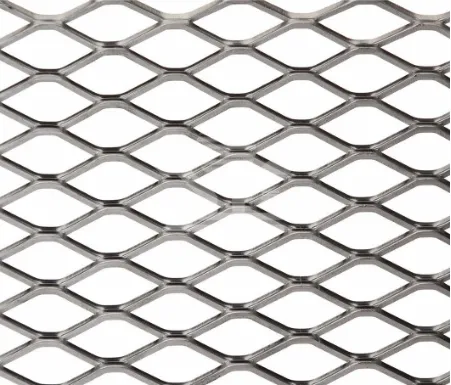

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP