2 月 . 07, 2025 03:29

Back to list

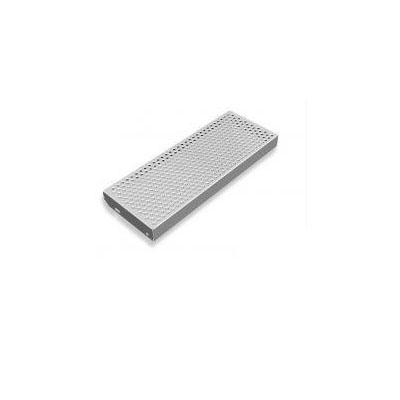

square perforated sheet metal

Square perforated sheet metal has carved out a niche as a versatile and essential material in various industries, from construction to electronics. With vast applications in diverse fields, understanding its unique advantages and uses is crucial for professionals seeking innovation and excellence in their projects.

From an environmental perspective, square perforated sheet metal supports sustainable practices due to its recyclability. The production process allows for minimal waste without sacrificing quality—a feature that resonates well with organizations committed to reducing their carbon footprint. By choosing recyclable materials, businesses can align their operational practices with global sustainability goals. Furthermore, the versatility of square perforated sheet metal extends to the agricultural sector, where it plays a critical role in drying and sorting systems. The open area facilitates efficient water drainage and aeration, which is integral for processes such as grain drying. Its durability ensures it withstands the vigorous demands of agricultural environments, providing a reliable solution year after year. Safety is another key factor driving the preference for square perforated sheet metal. It is frequently employed in the production of safety guards and protective barriers in machinery and industrial settings. The material’s strength and resistance prevent injuries and mishaps, enhancing workplace safety standards. When it comes to installation and maintenance, square perforated sheet metal offers significant advantages. Its uniform design allows for straightforward alignment and assembly, reducing labor costs and time. Maintenance is equally hassle-free, as the material is generally resistant to corrosion and requires minimal upkeep. This reliability underscores its cost-effectiveness over the long term, making it a sound investment. Professionals and businesses leveraging square perforated sheet metal benefit from a material that embodies expertise in design and functionality. Each application harnesses its unique properties, making it an exceptional choice across various industrial and commercial landscapes. Whether it’s enhancing building aesthetics, improving system performances, or contributing to sustainability, square perforated sheet metal continues to be a favored material that stands the test of time and meets the demanding standards of modern industries.

From an environmental perspective, square perforated sheet metal supports sustainable practices due to its recyclability. The production process allows for minimal waste without sacrificing quality—a feature that resonates well with organizations committed to reducing their carbon footprint. By choosing recyclable materials, businesses can align their operational practices with global sustainability goals. Furthermore, the versatility of square perforated sheet metal extends to the agricultural sector, where it plays a critical role in drying and sorting systems. The open area facilitates efficient water drainage and aeration, which is integral for processes such as grain drying. Its durability ensures it withstands the vigorous demands of agricultural environments, providing a reliable solution year after year. Safety is another key factor driving the preference for square perforated sheet metal. It is frequently employed in the production of safety guards and protective barriers in machinery and industrial settings. The material’s strength and resistance prevent injuries and mishaps, enhancing workplace safety standards. When it comes to installation and maintenance, square perforated sheet metal offers significant advantages. Its uniform design allows for straightforward alignment and assembly, reducing labor costs and time. Maintenance is equally hassle-free, as the material is generally resistant to corrosion and requires minimal upkeep. This reliability underscores its cost-effectiveness over the long term, making it a sound investment. Professionals and businesses leveraging square perforated sheet metal benefit from a material that embodies expertise in design and functionality. Each application harnesses its unique properties, making it an exceptional choice across various industrial and commercial landscapes. Whether it’s enhancing building aesthetics, improving system performances, or contributing to sustainability, square perforated sheet metal continues to be a favored material that stands the test of time and meets the demanding standards of modern industries.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP