2 月 . 07, 2025 03:05

Back to list

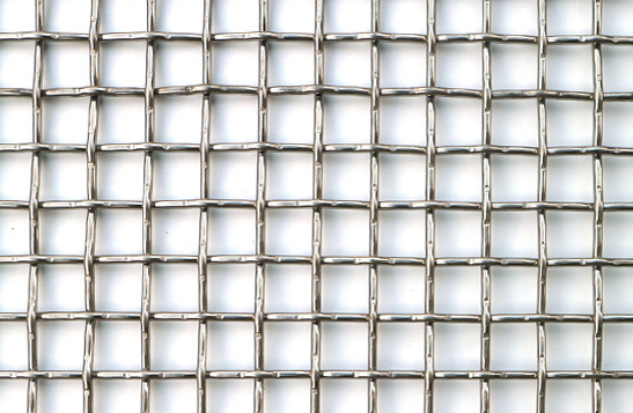

stamped metal sheets

Stamped metal sheets have been a cornerstone in both industrial applications and consumer products, making an indelible impact on manufacturing processes across sectors. Their versatility and robust nature have elevated them to a go-to material for businesses aiming to deliver quality and longevity in their offerings.

The environmental impact of stamped metal sheets is also a growing consideration. Given the global push towards sustainable practices, many manufacturers are opting for eco-friendly materials and recycling practices that minimize waste and reduce the carbon footprint. Metal stamping processes have adapted to these demands by incorporating scrap recycling and efficient use of resources, bolstering the trustworthiness of stamped metal solutions from an ecological standpoint. From a professional expertise perspective, the application of stamped metal sheets in technologically advanced sectors like electronics cannot be ignored. The precision required for components such as circuit boards and connectors makes stamped metals an ideal choice, guaranteeing minimal deviation in high-stakes manufacturing environments. Moreover, the adaptability of stamped metal sheets lends itself to innovation. Prototypes can be developed rapidly, allowing engineers to test new designs and features efficiently. This flexibility accelerates the product development cycle and brings cutting-edge solutions to market faster. Consequently, companies that harness the potential of stamped metal sheets often gain a competitive edge, standing as industry leaders through continuous innovation. Finally, in illustrating the authority of stamped metal sheet usage, one can examine their successful implementation in safety-critical components. Parts such as brake pads, airbags, and structural supports rely on the undoubted strength and reliability that stamped metal affords. Industries governed by stringent safety standards frequently cite stamped metal sheets as integral to maintaining compliance and performance standards. In conclusion, stamped metal sheets are the nexus of durability, efficiency, and innovation in manufacturing. By embracing advanced stamping technologies, corporations not only meet demanding production metrics but also champion environmental sustainability and product excellence. As the industrial landscape evolves, the authoritative role of stamped metal sheets in driving product success and sustainability undeniably stands tall.

The environmental impact of stamped metal sheets is also a growing consideration. Given the global push towards sustainable practices, many manufacturers are opting for eco-friendly materials and recycling practices that minimize waste and reduce the carbon footprint. Metal stamping processes have adapted to these demands by incorporating scrap recycling and efficient use of resources, bolstering the trustworthiness of stamped metal solutions from an ecological standpoint. From a professional expertise perspective, the application of stamped metal sheets in technologically advanced sectors like electronics cannot be ignored. The precision required for components such as circuit boards and connectors makes stamped metals an ideal choice, guaranteeing minimal deviation in high-stakes manufacturing environments. Moreover, the adaptability of stamped metal sheets lends itself to innovation. Prototypes can be developed rapidly, allowing engineers to test new designs and features efficiently. This flexibility accelerates the product development cycle and brings cutting-edge solutions to market faster. Consequently, companies that harness the potential of stamped metal sheets often gain a competitive edge, standing as industry leaders through continuous innovation. Finally, in illustrating the authority of stamped metal sheet usage, one can examine their successful implementation in safety-critical components. Parts such as brake pads, airbags, and structural supports rely on the undoubted strength and reliability that stamped metal affords. Industries governed by stringent safety standards frequently cite stamped metal sheets as integral to maintaining compliance and performance standards. In conclusion, stamped metal sheets are the nexus of durability, efficiency, and innovation in manufacturing. By embracing advanced stamping technologies, corporations not only meet demanding production metrics but also champion environmental sustainability and product excellence. As the industrial landscape evolves, the authoritative role of stamped metal sheets in driving product success and sustainability undeniably stands tall.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP