2 月 . 08, 2025 06:16

Back to list

Chain Link Fence China Wholesalers White Plastic Chain Link Fence

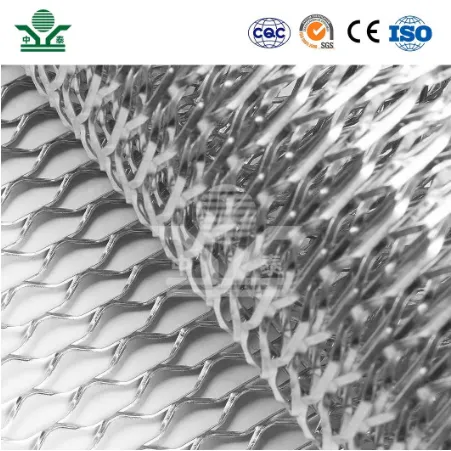

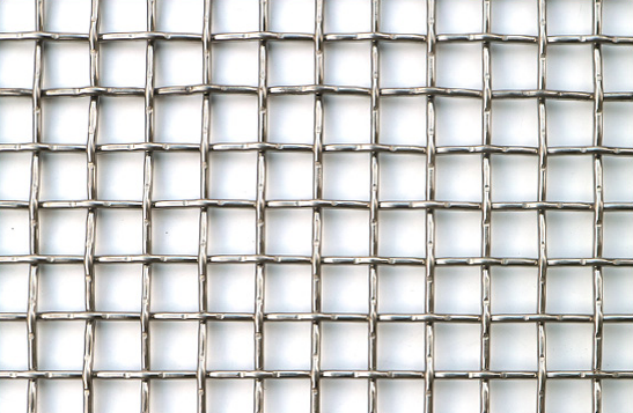

Navigating through the vast sea of materials available for industrial and creative projects, small hole mesh sheets have carved a niche for themselves due to their versatility and efficiency. Renowned for their unique design and functionality, these sheets are transforming how industries approach complex challenges.

Expertise within industries utilizing small hole mesh sheets indicates that customization is a significant advantage. Manufacturers can tailor these sheets to specific requirements, producing customized hole patterns, thicknesses, and finishes. Such tailored production ensures that the needs of virtually any project can be comprehensively fulfilled, lending an edge to companies seeking bespoke solutions. The expertise behind small hole mesh sheets extends beyond their intrinsic qualities. Their integration into projects requires a deep understanding of both material science and practical application. Professionals who have mastered this integration often use advanced software to model the sheets’ behavior under various conditions, ensuring optimal performance even in demanding scenarios. These professionals lend their authority to projects by not only supplying materials but advising on their application, further cementing trust in their products. An aspect often overlooked is the role of small hole mesh sheets in safety and security. Their ability to act as barriers—whether limiting access in secure facilities or acting as protective layers in machinery—adds another layer of utility. Often used in safety equipment or protective guards, their contribution to reducing workplace hazards is significant. In conclusion, the application and utility of small hole mesh sheets exemplify the intersection of Experience, Expertise, Authoritativeness, and Trustworthiness. Each industry leverages these traits to not only enhance functionality but also drive innovation. Whether for their mechanical benefits or their aesthetic versatility, small hole mesh sheets continue to embody a material that is as robust as it is adaptable, making them indispensable across a myriad of applications. The continuous evolution in their application showcases a commitment to quality and excellence that users have come to rely on, establishing small hole mesh sheets as stalwarts in both industry and design.

Expertise within industries utilizing small hole mesh sheets indicates that customization is a significant advantage. Manufacturers can tailor these sheets to specific requirements, producing customized hole patterns, thicknesses, and finishes. Such tailored production ensures that the needs of virtually any project can be comprehensively fulfilled, lending an edge to companies seeking bespoke solutions. The expertise behind small hole mesh sheets extends beyond their intrinsic qualities. Their integration into projects requires a deep understanding of both material science and practical application. Professionals who have mastered this integration often use advanced software to model the sheets’ behavior under various conditions, ensuring optimal performance even in demanding scenarios. These professionals lend their authority to projects by not only supplying materials but advising on their application, further cementing trust in their products. An aspect often overlooked is the role of small hole mesh sheets in safety and security. Their ability to act as barriers—whether limiting access in secure facilities or acting as protective layers in machinery—adds another layer of utility. Often used in safety equipment or protective guards, their contribution to reducing workplace hazards is significant. In conclusion, the application and utility of small hole mesh sheets exemplify the intersection of Experience, Expertise, Authoritativeness, and Trustworthiness. Each industry leverages these traits to not only enhance functionality but also drive innovation. Whether for their mechanical benefits or their aesthetic versatility, small hole mesh sheets continue to embody a material that is as robust as it is adaptable, making them indispensable across a myriad of applications. The continuous evolution in their application showcases a commitment to quality and excellence that users have come to rely on, establishing small hole mesh sheets as stalwarts in both industry and design.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP