2 月 . 08, 2025 05:48

Back to list

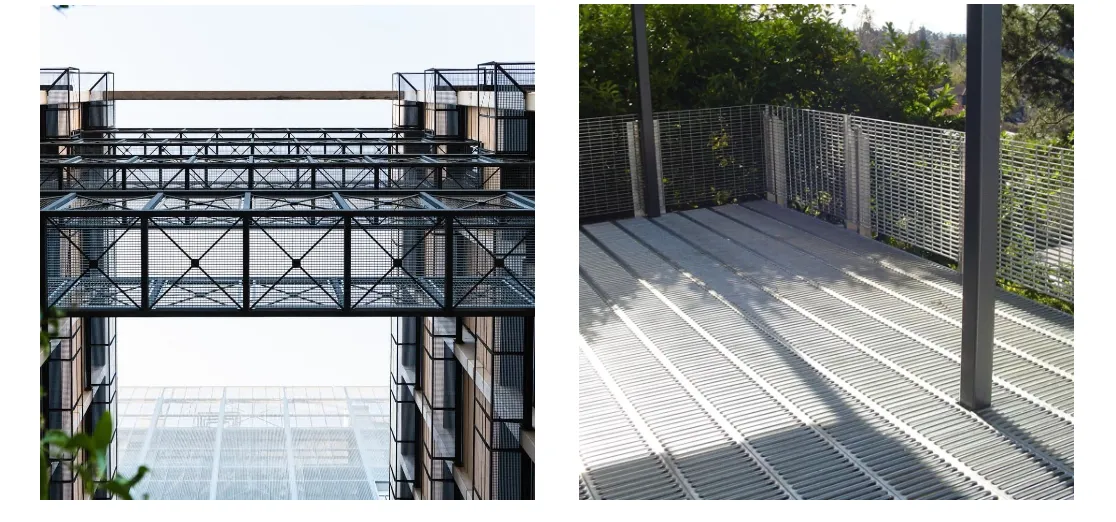

square hole perforated sheet

Square hole perforated sheets have become a staple in numerous industries due to their versatility, durability, and aesthetic appeal. These sheets are distinguished by a series of square-shaped holes that are uniformly punched into the metal, creating a pattern that serves both functional and decorative purposes. This article delves into the unique aspects and applications of square hole perforated sheets, offering insights from industry experts to highlight their practical benefits and user experiences.

Expertise in the field also emphasizes the importance of considering sheet thickness and hole size. These factors influence the sheet’s performance in various applications, such as ventilation and acoustic management. Thinner sheets with larger holes provide greater airflow, which is beneficial for HVAC systems, while thicker sheets with smaller holes offer enhanced sound attenuation properties, making them ideal for noise control barriers in urban environments. The customizability of square hole perforated sheets cannot be overstated. Manufacturers offer a vast array of sizes, hole patterns, and finishes to meet the specific requirements of each client. This level of customization is a testament to the sheets’ adaptability across different sectors, from agriculture to aerospace. For example, in the automotive industry, these sheets are increasingly used for both functional and decorative purposes, such as in grilles that improve engine cooling while contributing to the car's sleek appearance. One of the most frequently mentioned testimonials from users of square hole perforated sheets is their ease of installation and maintenance. Their lightweight nature reduces the labor required during installation, and their resilience to wear and tear minimizes the need for ongoing maintenance. This combination of ease and efficiency results in significant cost savings over time, an aspect that appeals to both commercial and private users. In summary, square hole perforated sheets have proven their worth through a combination of adaptability, durability, and aesthetic versatility. Their wide-ranging applications across various industries underscore the importance of understanding both the technical aspects of production and the practical needs of end users. As experts in the field continually refine the processes and materials used, the future looks promising for these multifunctional sheets, ensuring they remain a crucial component in both modern construction and industrial innovation.

Expertise in the field also emphasizes the importance of considering sheet thickness and hole size. These factors influence the sheet’s performance in various applications, such as ventilation and acoustic management. Thinner sheets with larger holes provide greater airflow, which is beneficial for HVAC systems, while thicker sheets with smaller holes offer enhanced sound attenuation properties, making them ideal for noise control barriers in urban environments. The customizability of square hole perforated sheets cannot be overstated. Manufacturers offer a vast array of sizes, hole patterns, and finishes to meet the specific requirements of each client. This level of customization is a testament to the sheets’ adaptability across different sectors, from agriculture to aerospace. For example, in the automotive industry, these sheets are increasingly used for both functional and decorative purposes, such as in grilles that improve engine cooling while contributing to the car's sleek appearance. One of the most frequently mentioned testimonials from users of square hole perforated sheets is their ease of installation and maintenance. Their lightweight nature reduces the labor required during installation, and their resilience to wear and tear minimizes the need for ongoing maintenance. This combination of ease and efficiency results in significant cost savings over time, an aspect that appeals to both commercial and private users. In summary, square hole perforated sheets have proven their worth through a combination of adaptability, durability, and aesthetic versatility. Their wide-ranging applications across various industries underscore the importance of understanding both the technical aspects of production and the practical needs of end users. As experts in the field continually refine the processes and materials used, the future looks promising for these multifunctional sheets, ensuring they remain a crucial component in both modern construction and industrial innovation.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP