2 月 . 08, 2025 06:38

Back to list

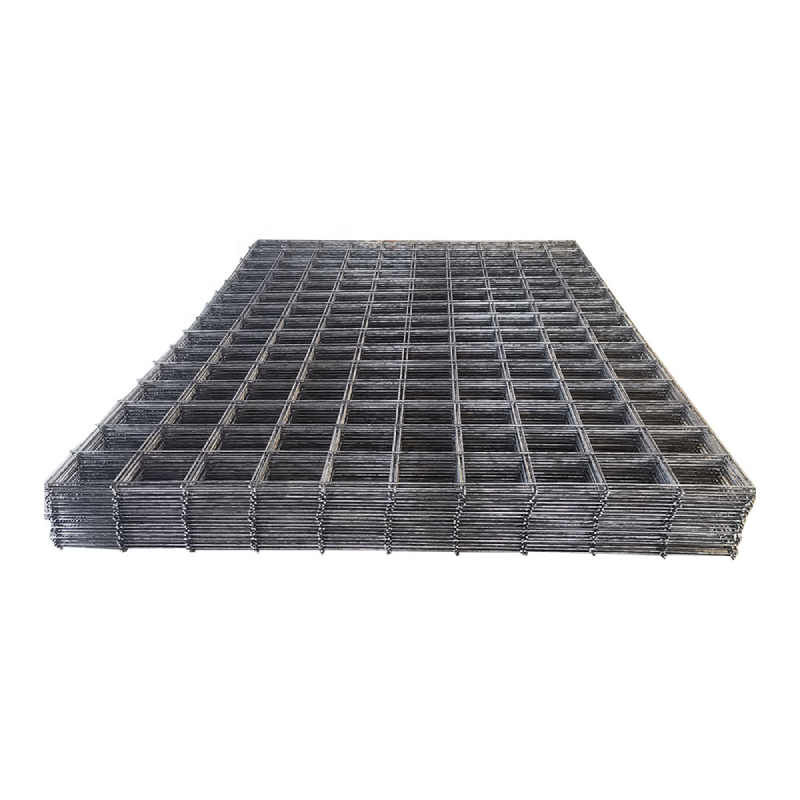

Welded Wire Mesh Supplier

Slotted stainless steel sheets are a pivotal component in numerous industrial and architectural applications, renowned for their versatility, durability, and aesthetic appeal. These sheets are crafted by integrating precision-engineered slots into high-quality stainless steel, thus enhancing both functionality and design possibilities. This article delves into the multifaceted benefits of slotted stainless steel sheets, underscoring their relevance in modern industry and construction, while grounding our insights in expert analysis and real-world experience.

From an expert viewpoint, selecting the right grade of stainless steel is crucial when considering slotted sheets. Grades such as 304 and 316 offer varying levels of corrosion resistance and strength, with 316 being especially suited for marine environments due to its enhanced anti-corrosive properties. Professional guidance and technical specifications are essential in ensuring that the chosen material aligns with the specific demands of your project, whether industrial or architectural. Authoritative sources in material science emphasize the importance of precision in the manufacture of slotted stainless steel sheets. State-of-the-art manufacturing processes, such as laser cutting and CNC machining, are pivotal in achieving the precise tolerances necessary for high-performance applications. These advanced methodologies ensure that each sheet meets stringent quality standards, providing reliability and consistency across all uses. Trustworthiness in sourcing these sheets cannot be overstated. Reputable suppliers should be able to demonstrate compliance with industry standards, such as those set by the International Organization for Standardization (ISO). Furthermore, building strong relationships with manufacturers that have a proven track record in producing high-quality, certified products enhances the assurance of quality and performance. In conclusion, slotted stainless steel sheets are indispensable in both industrial and architectural realms, offering unparalleled durability, customization, and aesthetic appeal. By emphasizing expertise and trust in their production and application, these sheets continue to meet and exceed the demands of modern engineering and design. Whether you are a project manager in an industrial setting or an architect working on innovative designs, choosing slotted stainless steel sheets backed by expert manufacturing processes and reliable suppliers ensures success and satisfaction in your projects.

From an expert viewpoint, selecting the right grade of stainless steel is crucial when considering slotted sheets. Grades such as 304 and 316 offer varying levels of corrosion resistance and strength, with 316 being especially suited for marine environments due to its enhanced anti-corrosive properties. Professional guidance and technical specifications are essential in ensuring that the chosen material aligns with the specific demands of your project, whether industrial or architectural. Authoritative sources in material science emphasize the importance of precision in the manufacture of slotted stainless steel sheets. State-of-the-art manufacturing processes, such as laser cutting and CNC machining, are pivotal in achieving the precise tolerances necessary for high-performance applications. These advanced methodologies ensure that each sheet meets stringent quality standards, providing reliability and consistency across all uses. Trustworthiness in sourcing these sheets cannot be overstated. Reputable suppliers should be able to demonstrate compliance with industry standards, such as those set by the International Organization for Standardization (ISO). Furthermore, building strong relationships with manufacturers that have a proven track record in producing high-quality, certified products enhances the assurance of quality and performance. In conclusion, slotted stainless steel sheets are indispensable in both industrial and architectural realms, offering unparalleled durability, customization, and aesthetic appeal. By emphasizing expertise and trust in their production and application, these sheets continue to meet and exceed the demands of modern engineering and design. Whether you are a project manager in an industrial setting or an architect working on innovative designs, choosing slotted stainless steel sheets backed by expert manufacturing processes and reliable suppliers ensures success and satisfaction in your projects.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP