2 月 . 12, 2025 09:32

Back to list

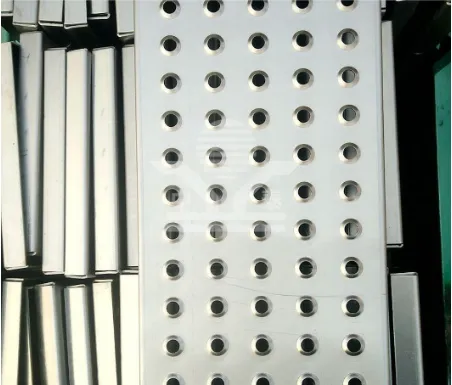

perforated galvanized steel sheet

Perforated galvanized steel sheets have emerged as a versatile material, offering incredible durability while maintaining aesthetic appeal. For contractors, designers, and DIY enthusiasts, understanding the application and advantages of these sheets is imperative to making informed choices for various projects.

Many professionals point to the environmental benefits of using galvanized steel as another compelling reason to opt for these materials. Galvanized steel is fully recyclable, and its longevity means fewer replacements and less waste over time. This sustainability aspect adds a layer of appeal for modern projects where eco-friendliness is a desired attribute. Trustworthiness and authority in the industry are garnered through consistent quality and reliability. Reputable manufacturers adhere to industry standards to ensure the perforated sheets meet specifications for various uses. Investing in well-sourced products from trusted suppliers is essential to securing materials that will perform under the expected conditions. When considering installation, it's critical to work with professionals who understand the nuances of working with perforated galvanized steel. Incorrect installation can compromise the material's integrity and effectiveness, so engaging skilled craftsmen or teams with a history of successful implementations is advisable. Maintenance of these sheets is relatively hassle-free. The zinc coating that discourages rust also simplifies the cleaning process. Routine inspections and light cleaning are generally all that's needed to keep the materials in top condition, an advantageous trait for both industrial applications and decorative uses. In conclusion, perforated galvanized steel sheets represent a blend of aesthetic and functional characteristics that far outperform many traditional materials. Their adaptability across various domains, from construction to design, underscores their value. With comprehensive expertise in selection and application, and assurance of authenticity and quality from trusted sources, these steel sheets offer a reliable, durable, and aesthetically pleasing solution for those seeking to innovate and enhance their projects.

Many professionals point to the environmental benefits of using galvanized steel as another compelling reason to opt for these materials. Galvanized steel is fully recyclable, and its longevity means fewer replacements and less waste over time. This sustainability aspect adds a layer of appeal for modern projects where eco-friendliness is a desired attribute. Trustworthiness and authority in the industry are garnered through consistent quality and reliability. Reputable manufacturers adhere to industry standards to ensure the perforated sheets meet specifications for various uses. Investing in well-sourced products from trusted suppliers is essential to securing materials that will perform under the expected conditions. When considering installation, it's critical to work with professionals who understand the nuances of working with perforated galvanized steel. Incorrect installation can compromise the material's integrity and effectiveness, so engaging skilled craftsmen or teams with a history of successful implementations is advisable. Maintenance of these sheets is relatively hassle-free. The zinc coating that discourages rust also simplifies the cleaning process. Routine inspections and light cleaning are generally all that's needed to keep the materials in top condition, an advantageous trait for both industrial applications and decorative uses. In conclusion, perforated galvanized steel sheets represent a blend of aesthetic and functional characteristics that far outperform many traditional materials. Their adaptability across various domains, from construction to design, underscores their value. With comprehensive expertise in selection and application, and assurance of authenticity and quality from trusted sources, these steel sheets offer a reliable, durable, and aesthetically pleasing solution for those seeking to innovate and enhance their projects.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP