2 月 . 12, 2025 08:55

Back to list

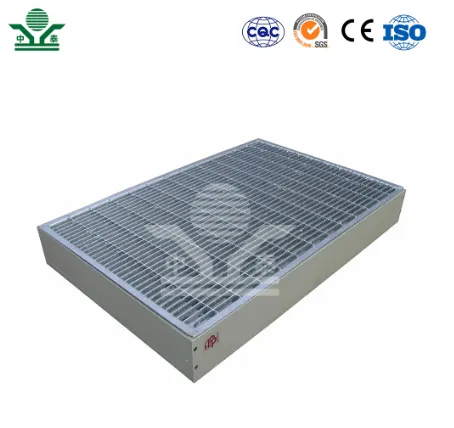

perforated iron sheet

Perforated iron sheets have emerged as an indispensable material across numerous industries, offering a blend of strength, versatility, and aesthetic appeal. These sheets are iron panels punctuated with a series of holes, providing multiple benefits ranging from functionality to design. The diverse applications of perforated iron sheets make them a prime choice for architects, designers, and engineers who are always on the lookout for materials that can deliver in both performance and aesthetics.

In terms of environmental impact, iron is a recyclable material that retains its properties even after multiple recycling processes. Utilizing perforated iron sheets aligns with sustainable building practices, as they contribute to reduced material wastage and can be repurposed at the end of their lifecycle. This is a significant consideration for modern construction projects where sustainability is no longer an option but a requirement. Furthermore, the production process of perforated iron sheets can be fine-tuned to ensure precision and efficiency. Advances in technology have enabled manufacturers to produce sheets with high accuracy, minimizing errors and reducing material waste. This not only ensures high-quality products but also promotes sustainability through less resource consumption. For industries prioritizing hygiene, such as food processing and health sectors, perforated iron sheets prove beneficial due to their easy cleaning properties. The non-porous surface of iron, combined with the customizable perforations, allows easy maintenance and reduces the chances of bacterial growth, facilitating compliance with health and safety standards. While the benefits of perforated iron sheets are vast, it is crucial to source these materials from reputable manufacturers known for quality and reliability. This guarantees that the sheets meet safety standards and specifications essential for intended applications. Trust and authority in manufacturers ensure a steady supply of top-grade materials, backed by industry certifications and customer support. In summary, perforated iron sheets are a multifaceted material that stands out in the fields of architecture, engineering, and design. Their strength, versatility, aesthetic appeal, and practical properties support a wide array of applications, from creating spectacular building facades to integrating sustainable practices in industrial projects. Understanding the unique advantages offered by perforated iron sheets allows professionals to leverage these benefits, fostering innovation and efficiency in their respective fields. By continuously exploring the potential uses of perforated iron sheets, industries can effectively respond to the ever-evolving demands of modern construction and design, thus forging a path towards sustainable and efficient solutions.

In terms of environmental impact, iron is a recyclable material that retains its properties even after multiple recycling processes. Utilizing perforated iron sheets aligns with sustainable building practices, as they contribute to reduced material wastage and can be repurposed at the end of their lifecycle. This is a significant consideration for modern construction projects where sustainability is no longer an option but a requirement. Furthermore, the production process of perforated iron sheets can be fine-tuned to ensure precision and efficiency. Advances in technology have enabled manufacturers to produce sheets with high accuracy, minimizing errors and reducing material waste. This not only ensures high-quality products but also promotes sustainability through less resource consumption. For industries prioritizing hygiene, such as food processing and health sectors, perforated iron sheets prove beneficial due to their easy cleaning properties. The non-porous surface of iron, combined with the customizable perforations, allows easy maintenance and reduces the chances of bacterial growth, facilitating compliance with health and safety standards. While the benefits of perforated iron sheets are vast, it is crucial to source these materials from reputable manufacturers known for quality and reliability. This guarantees that the sheets meet safety standards and specifications essential for intended applications. Trust and authority in manufacturers ensure a steady supply of top-grade materials, backed by industry certifications and customer support. In summary, perforated iron sheets are a multifaceted material that stands out in the fields of architecture, engineering, and design. Their strength, versatility, aesthetic appeal, and practical properties support a wide array of applications, from creating spectacular building facades to integrating sustainable practices in industrial projects. Understanding the unique advantages offered by perforated iron sheets allows professionals to leverage these benefits, fostering innovation and efficiency in their respective fields. By continuously exploring the potential uses of perforated iron sheets, industries can effectively respond to the ever-evolving demands of modern construction and design, thus forging a path towards sustainable and efficient solutions.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP