2 月 . 12, 2025 09:57

Back to list

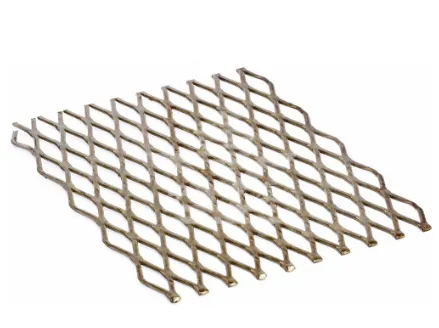

perforated galvanized sheet metal

Perforated galvanized sheet metal has become an essential component in various industries due to its combination of durability, versatility, and aesthetic appeal. This article delves into the many facets that make perforated galvanized sheet metal a preferred choice among professionals, from construction to design, offering valuable insights based on extensive experience and expertise.

Trustworthiness in a material comes from proven reliability in real-world applications. In projects where safety is paramount, such as in urban infrastructure or public spaces, engineers rely on the consistent performance of galvanized sheet metal. Its non-combustible nature and resistance to damage by pests such as termites offer peace of mind that few other materials can match. An authoritative aspect of perforated galvanized sheet metal is its widespread compliance with industry standards. It meets stringent criteria for performance and safety across different regions, underscoring its reliability and adaptability. Whether it's conformity with ASTM standards or adherence to European EN norms, this material is recognized for meeting the highest quality benchmarks. The sustainability aspect further enhances trust in perforated galvanized sheet metal. Zinc is a naturally occurring element that is abundant and recyclable, making the material an eco-friendly choice. The longevity and minimal maintenance required also contribute to its environmental credentials, reducing the need for frequent replacements or repairs. To optimize the use of perforated galvanized sheet metal, expertise in selection and installation is paramount. Consulting with seasoned professionals in the field can greatly enhance the outcome of a project. For instance, proper consideration of the perforation pattern, hole size, and gauge ensures that the material not only meets aesthetic expectations but also fulfills structural and functional roles effectively. In conclusion, perforated galvanized sheet metal exemplifies a blend of durability, versatility, and aesthetic appeal that is seldom matched by other materials. Its proven performance, backed by industry standards, makes it a go-to choice for architects, engineers, and designers seeking a reliable solution across a spectrum of applications. With the growing emphasis on sustainable practices, the material's recyclability and minimal environmental impact further solidify its position as a modern-day staple in construction and design.

Trustworthiness in a material comes from proven reliability in real-world applications. In projects where safety is paramount, such as in urban infrastructure or public spaces, engineers rely on the consistent performance of galvanized sheet metal. Its non-combustible nature and resistance to damage by pests such as termites offer peace of mind that few other materials can match. An authoritative aspect of perforated galvanized sheet metal is its widespread compliance with industry standards. It meets stringent criteria for performance and safety across different regions, underscoring its reliability and adaptability. Whether it's conformity with ASTM standards or adherence to European EN norms, this material is recognized for meeting the highest quality benchmarks. The sustainability aspect further enhances trust in perforated galvanized sheet metal. Zinc is a naturally occurring element that is abundant and recyclable, making the material an eco-friendly choice. The longevity and minimal maintenance required also contribute to its environmental credentials, reducing the need for frequent replacements or repairs. To optimize the use of perforated galvanized sheet metal, expertise in selection and installation is paramount. Consulting with seasoned professionals in the field can greatly enhance the outcome of a project. For instance, proper consideration of the perforation pattern, hole size, and gauge ensures that the material not only meets aesthetic expectations but also fulfills structural and functional roles effectively. In conclusion, perforated galvanized sheet metal exemplifies a blend of durability, versatility, and aesthetic appeal that is seldom matched by other materials. Its proven performance, backed by industry standards, makes it a go-to choice for architects, engineers, and designers seeking a reliable solution across a spectrum of applications. With the growing emphasis on sustainable practices, the material's recyclability and minimal environmental impact further solidify its position as a modern-day staple in construction and design.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP