2 月 . 12, 2025 10:36

Back to list

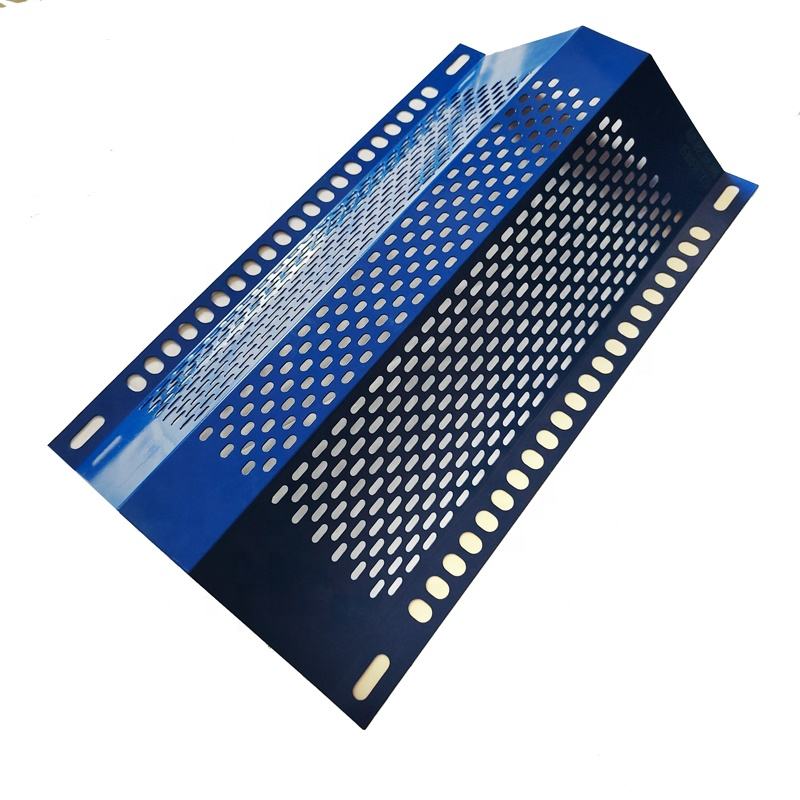

perforated galvanised steel sheet

Perforated galvanized steel sheets have carved a niche for themselves in various industrial and architectural applications due to their exemplary blend of functionality and aesthetics. To gain true value from these versatile materials, it's important to delve into their unique characteristics, practical applications, and the expertise involved in selecting and utilizing them.

Authority in the market for perforated galvanized steel sheets comes from a combination of industry recognition and technological advancement. Leading manufacturers often employ state-of-the-art techniques in perforation methods, ensuring precision and consistency across products. This technological prowess, coupled with certifications like ISO 9001 for quality management, establishes a company as a trusted supplier in the industry. Trustworthiness is paramount when selecting suppliers for these materials. Reputable suppliers offer comprehensive warranties, transparent communication regarding product specifications, and deliver consistent post-sale support. Furthermore, they will provide evidence of compliance with international standards like ASTM A653 for hot-dip galvanized steel, which guarantees the material's mechanical properties and zinc coating adherence. An experienced contractor or architect working with perforated galvanized steel sheets also understands the importance of installation expertise. Proper handling and installation are crucial to prevent damage to the protective galvanization layer. Contractors adept in this field will ensure that the sheets are appropriately installed, considering factors like sheet weight, support framework, and environmental exposure to maximize the material's life and performance. In summary, the strategic use of perforated galvanized steel sheets hinges on a profound understanding of their inherent benefits, coupled with expertise in selection and installation. The unique properties of these materials offer superior solutions across architectural and industrial domains, where both aesthetics and functionality are paramount. As the demand for sustainable and cost-effective materials grows, these versatile sheets continue to be a material of choice, combining the ageless strength of steel with the technological advancement of modern engineering. By prioritizing quality, authoritative suppliers and expert contractors, projects utilizing perforated galvanized steel sheets can achieve outstanding results and long-term success.

Authority in the market for perforated galvanized steel sheets comes from a combination of industry recognition and technological advancement. Leading manufacturers often employ state-of-the-art techniques in perforation methods, ensuring precision and consistency across products. This technological prowess, coupled with certifications like ISO 9001 for quality management, establishes a company as a trusted supplier in the industry. Trustworthiness is paramount when selecting suppliers for these materials. Reputable suppliers offer comprehensive warranties, transparent communication regarding product specifications, and deliver consistent post-sale support. Furthermore, they will provide evidence of compliance with international standards like ASTM A653 for hot-dip galvanized steel, which guarantees the material's mechanical properties and zinc coating adherence. An experienced contractor or architect working with perforated galvanized steel sheets also understands the importance of installation expertise. Proper handling and installation are crucial to prevent damage to the protective galvanization layer. Contractors adept in this field will ensure that the sheets are appropriately installed, considering factors like sheet weight, support framework, and environmental exposure to maximize the material's life and performance. In summary, the strategic use of perforated galvanized steel sheets hinges on a profound understanding of their inherent benefits, coupled with expertise in selection and installation. The unique properties of these materials offer superior solutions across architectural and industrial domains, where both aesthetics and functionality are paramount. As the demand for sustainable and cost-effective materials grows, these versatile sheets continue to be a material of choice, combining the ageless strength of steel with the technological advancement of modern engineering. By prioritizing quality, authoritative suppliers and expert contractors, projects utilizing perforated galvanized steel sheets can achieve outstanding results and long-term success.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP