2 月 . 12, 2025 11:14

Back to list

perforated galvanised sheet

Perforated galvanised sheets are revolutionizing several industries, offering a unique combination of strength, versatility, and aesthetic appeal. As markets evolve, the demand for materials that can adapt to diverse requirements has made perforated galvanised sheets an invaluable resource. Here, we delve into the essential aspects of these sheets, emphasizing their benefits, applications, and why they should be your material of choice for your next project.

The manufacturing sector benefits greatly from perforated galvanised sheets as well, particularly in fabrication and assembly processes. These sheets are lightweight yet robust, contributing to easier handling and transportation, which streamlines operations and reduces logistical expenditures. Their flexibility allows them to be easily manipulated into different shapes and sizes, meeting the diverse demands of manufacturing processes ranging from automotive production to electronic equipment casing. Trust in the quality of perforated galvanised sheets is supported by industry standards and certifications that guarantee performance. These standards ensure the material's consistency in various industrial applications, assuring clients of their reliability and adherence to regulatory requirements. Engaging with reputable suppliers who offer certified products can significantly enhance a project's outcome and customer satisfaction. When considering sustainability, perforated galvanised sheets are an environmentally friendly option. The sheets' longevity means that resources are conserved over time, reducing the need for frequent replacements. Additionally, galvanised steel is recyclable, further underscoring its role in promoting sustainability within industrial practices. Engineers and project managers can confidently include these sheets in eco-friendly projects without compromising on quality or durability. In summary, perforated galvanised sheets are an exceptional choice for a myriad of applications, thanks to their robustness, versatility, and aesthetic potential. They offer real advantages in industries ranging from construction to manufacturing, underpinned by durability, ease of use, and a broad range of functional benefits. When prioritizing sustainability and performance, these sheets provide a reliable, cost-effective solution that meets industry standards and exceeds client expectations. Companies and professionals looking to leverage the full potential of their projects should consider incorporating perforated galvanised sheets, not only for their practical benefits but also for their contribution to creating innovative and sustainable solutions.

The manufacturing sector benefits greatly from perforated galvanised sheets as well, particularly in fabrication and assembly processes. These sheets are lightweight yet robust, contributing to easier handling and transportation, which streamlines operations and reduces logistical expenditures. Their flexibility allows them to be easily manipulated into different shapes and sizes, meeting the diverse demands of manufacturing processes ranging from automotive production to electronic equipment casing. Trust in the quality of perforated galvanised sheets is supported by industry standards and certifications that guarantee performance. These standards ensure the material's consistency in various industrial applications, assuring clients of their reliability and adherence to regulatory requirements. Engaging with reputable suppliers who offer certified products can significantly enhance a project's outcome and customer satisfaction. When considering sustainability, perforated galvanised sheets are an environmentally friendly option. The sheets' longevity means that resources are conserved over time, reducing the need for frequent replacements. Additionally, galvanised steel is recyclable, further underscoring its role in promoting sustainability within industrial practices. Engineers and project managers can confidently include these sheets in eco-friendly projects without compromising on quality or durability. In summary, perforated galvanised sheets are an exceptional choice for a myriad of applications, thanks to their robustness, versatility, and aesthetic potential. They offer real advantages in industries ranging from construction to manufacturing, underpinned by durability, ease of use, and a broad range of functional benefits. When prioritizing sustainability and performance, these sheets provide a reliable, cost-effective solution that meets industry standards and exceeds client expectations. Companies and professionals looking to leverage the full potential of their projects should consider incorporating perforated galvanised sheets, not only for their practical benefits but also for their contribution to creating innovative and sustainable solutions.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

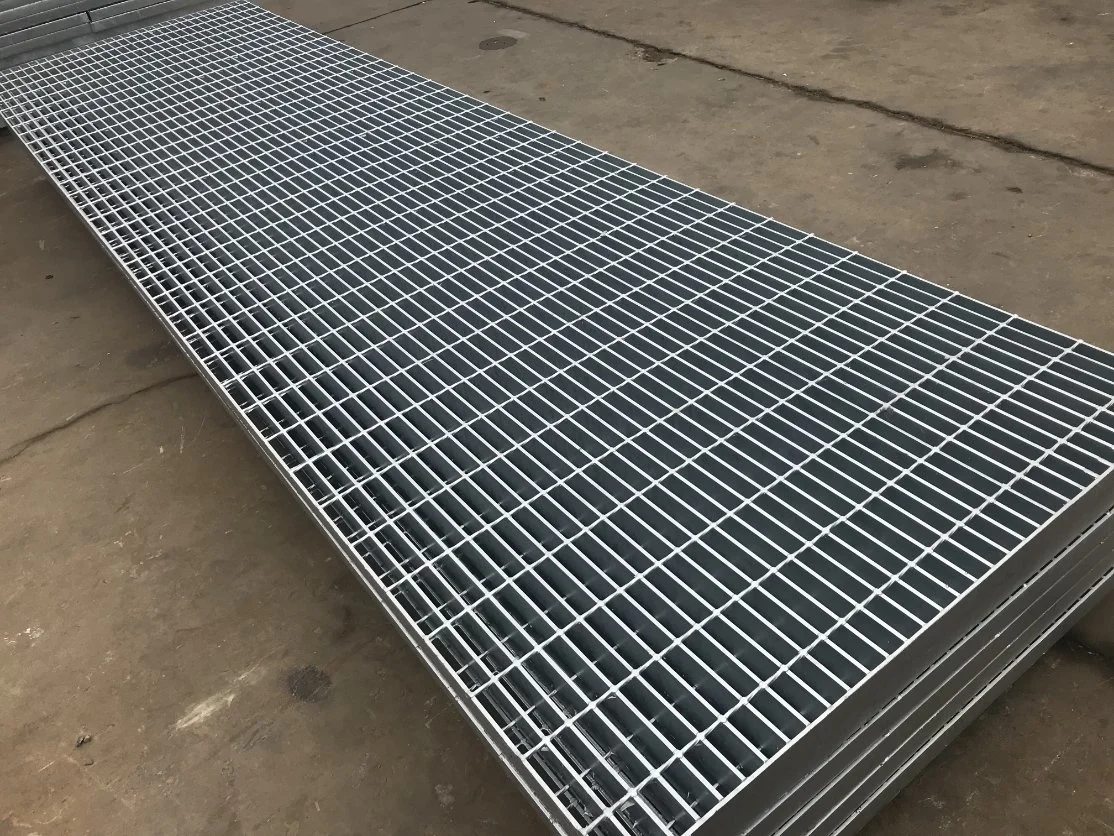

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP