2 月 . 12, 2025 13:33

Back to list

Chain Link Fence China Wholesalers White Plastic Chain Link Fence

Perforated corrugated metal panels have become an increasingly popular choice for architects and builders alike, thanks to their unique combination of aesthetic appeal and functional performance. These panels offer versatility and durability that fit seamlessly into various applications, from commercial to residential projects, making them an invaluable material in modern design and construction.

In terms of installation, perforated corrugated metal panels offer ease and speed, contributing to reduced labor costs and project timelines. Their lightweight nature simplifies handling and installation, allowing for quick assembly even in complex design scenarios. This efficiency does not compromise their performance or durability, making them an ideal choice for rapid construction projects without sacrificing quality. Despite the numerous benefits, selecting the right perforated corrugated metal panels requires careful consideration of several factors to maximize performance and aesthetic goals. Consultations with manufacturers or specialists can provide valuable insights into the optimal choice of material, thickness, and perforation pattern, ensuring the final product meets both functional and design specifications. Collaboration with experienced professionals brings expertise and credibility to any project incorporating perforated metal panels. Manufacturers often have extensive knowledge and capabilities in producing panels that meet exacting standards and specific client requirements. Seeking their advice early in the design process can lead to enhanced outcomes, including cost savings and better alignment with architectural and functional objectives. As a testament to their widespread adoption, prestigious architects and construction firms have incorporated perforated corrugated metal panels into landmark projects worldwide. Their use in high-profile structures serves as a validation of their design flexibility, durability, and performance capabilities. These real-world applications demonstrate the inherent trustworthiness of the material, inspiring confidence in potential adopters. With endless possibilities in design and application, perforated corrugated metal panels continue to shape the landscape of modern architecture and construction. Their adaptability and functional superiority make them indispensable in crafting the built environments of tomorrow. As the demand for sustainable and high-performance materials grows, these panels stand as a testament to innovation, driving future trends in construction and design with authority and expertise.

In terms of installation, perforated corrugated metal panels offer ease and speed, contributing to reduced labor costs and project timelines. Their lightweight nature simplifies handling and installation, allowing for quick assembly even in complex design scenarios. This efficiency does not compromise their performance or durability, making them an ideal choice for rapid construction projects without sacrificing quality. Despite the numerous benefits, selecting the right perforated corrugated metal panels requires careful consideration of several factors to maximize performance and aesthetic goals. Consultations with manufacturers or specialists can provide valuable insights into the optimal choice of material, thickness, and perforation pattern, ensuring the final product meets both functional and design specifications. Collaboration with experienced professionals brings expertise and credibility to any project incorporating perforated metal panels. Manufacturers often have extensive knowledge and capabilities in producing panels that meet exacting standards and specific client requirements. Seeking their advice early in the design process can lead to enhanced outcomes, including cost savings and better alignment with architectural and functional objectives. As a testament to their widespread adoption, prestigious architects and construction firms have incorporated perforated corrugated metal panels into landmark projects worldwide. Their use in high-profile structures serves as a validation of their design flexibility, durability, and performance capabilities. These real-world applications demonstrate the inherent trustworthiness of the material, inspiring confidence in potential adopters. With endless possibilities in design and application, perforated corrugated metal panels continue to shape the landscape of modern architecture and construction. Their adaptability and functional superiority make them indispensable in crafting the built environments of tomorrow. As the demand for sustainable and high-performance materials grows, these panels stand as a testament to innovation, driving future trends in construction and design with authority and expertise.

Latest news

-

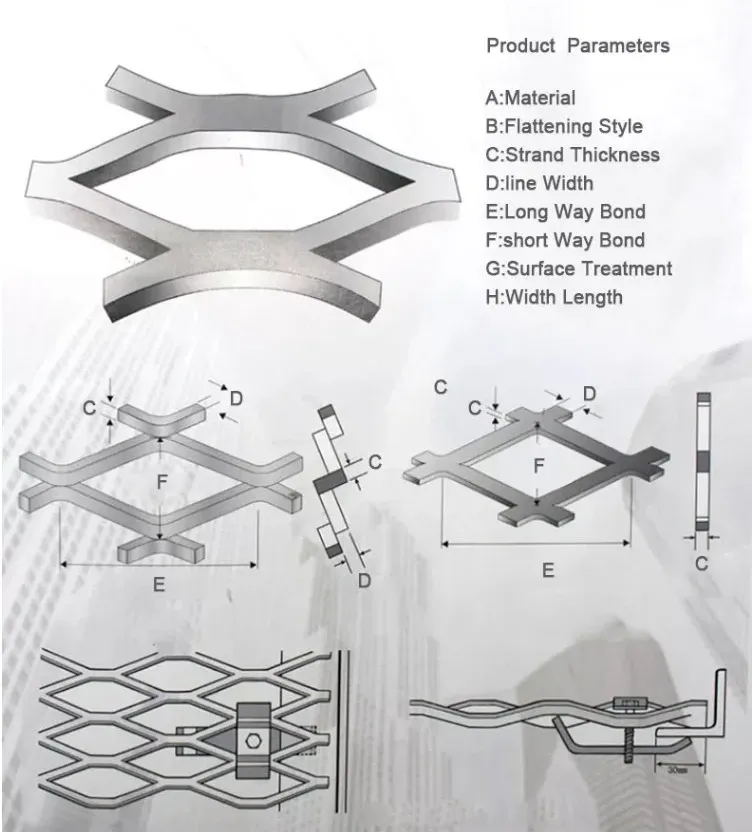

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP