2 月 . 12, 2025 12:58

Back to list

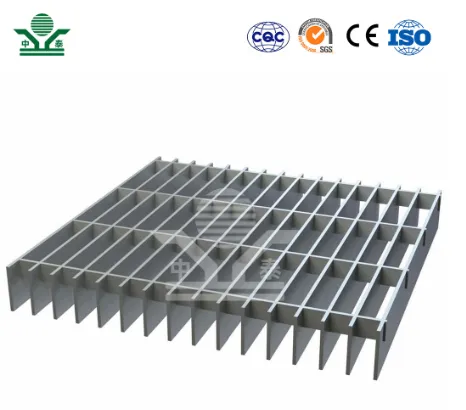

Zhongtai Grate Grill China Wholesalers Galvanized Trench Grates

In today's architectural and industrial landscape, perforated corrugated metal sheets have emerged as a groundbreaking solution that combines aesthetic appeal with functional ingenuity. These versatile materials have found applications across various fields, including construction, agriculture, and manufacturing, due to their unique characteristics and benefits.

In industrial settings, these sheets are often utilized for filtering and screening purposes. The customizable perforations provide an efficient means of separating particles and controlling fluid flow. This is particularly useful in industries like food processing or chemical manufacturing, where precision is paramount. The installation process of perforated corrugated metal sheets is straightforward and cost-effective, further bolstering their reputation as a practical choice. Thanks to the lightweight nature of the material, handling and assembly require less labor and time, translating into significant savings during large-scale projects. Ensuring a material's credibility in the market is crucial, and perforated corrugated metal sheets do not fall short in this area. Their widespread use and functional success stories have been documented in numerous case studies, reinforcing their reliability as a trusted material choice. Industry experts frequently advocate for their use, emphasizing the combination of functionality with unmatched aesthetic versatility. End-users, including engineers, architects, and builders, continually express confidence in the performance of these sheets. Subsequent to rigorous testing, these sheets have met stringent industry standards, certifying them as safe and durable for a broad spectrum of applications. Listening to users' feedback has driven innovation, ensuring ongoing development in their design and application, maintaining their relevance in a rapidly evolving industrial landscape. In conclusion, perforated corrugated metal sheets encapsulate a remarkable synergy between design and functionality. Their diverse applications, coupled with inherent strengths and eco-friendly nature, position them as a premier choice for modern-day construction and industrial needs. Future prospects seem promising, as advancements in technology may soon expand the possibilities of how these sheets are used, further strengthening their role as a pivotal material in creating sustainable and innovative solutions.

In industrial settings, these sheets are often utilized for filtering and screening purposes. The customizable perforations provide an efficient means of separating particles and controlling fluid flow. This is particularly useful in industries like food processing or chemical manufacturing, where precision is paramount. The installation process of perforated corrugated metal sheets is straightforward and cost-effective, further bolstering their reputation as a practical choice. Thanks to the lightweight nature of the material, handling and assembly require less labor and time, translating into significant savings during large-scale projects. Ensuring a material's credibility in the market is crucial, and perforated corrugated metal sheets do not fall short in this area. Their widespread use and functional success stories have been documented in numerous case studies, reinforcing their reliability as a trusted material choice. Industry experts frequently advocate for their use, emphasizing the combination of functionality with unmatched aesthetic versatility. End-users, including engineers, architects, and builders, continually express confidence in the performance of these sheets. Subsequent to rigorous testing, these sheets have met stringent industry standards, certifying them as safe and durable for a broad spectrum of applications. Listening to users' feedback has driven innovation, ensuring ongoing development in their design and application, maintaining their relevance in a rapidly evolving industrial landscape. In conclusion, perforated corrugated metal sheets encapsulate a remarkable synergy between design and functionality. Their diverse applications, coupled with inherent strengths and eco-friendly nature, position them as a premier choice for modern-day construction and industrial needs. Future prospects seem promising, as advancements in technology may soon expand the possibilities of how these sheets are used, further strengthening their role as a pivotal material in creating sustainable and innovative solutions.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP