2 月 . 12, 2025 23:10

Back to list

perforated aluminum mesh

Perforated aluminum mesh has emerged as one of the most versatile and efficient materials for various industrial and architectural applications. Its unique combination of strength, lightweight nature, and customizable characteristics make it an attractive choice for both commercial and residential projects. Below, we delve into the significant advantages, applications, and considerations of perforated aluminum mesh, grounded in years of professional expertise and real-world implementations.

On the expertise front, professionals stress the importance of understanding the specific needs of each project when choosing the pattern and thickness of the mesh. Optimal airflow, for instance, can be achieved through precise perforation patterns, enhancing ventilation in spaces such as offices and factories. Similarly, in architectural facades, both the aesthetic value and the performance can be fine-tuned to achieve a specific visual impact while benefiting from natural lighting and heat control. The authoritativeness of using perforated aluminum mesh is further demonstrated in numerous successful case studies worldwide. Prestigious buildings, artistic installations, and state-of-the-art infrastructure projects often showcase its use, attesting to the material's reliability and appeal. Leaders in architecture and engineering frequently cite its role in modern design paradigms, emphasizing sustainability and innovative construction techniques. Trustworthiness is paramount in material selection, particularly regarding safety and compliance with environmental standards. Perforated aluminum mesh's recyclability is a significant advantage amid growing concerns over sustainability in construction practices. Aluminum's ability to be recycled without losing its properties aligns with global efforts to reduce carbon footprints, reinforcing its credibility as a sustainable choice for conscientious builders and designers. In conclusion, whether for achieving cutting-edge architectural aesthetics or meeting strict industrial specifications, perforated aluminum mesh stands out by merging functional superiority with design flexibility. Its successful deployment across a multitude of scenarios underscores not only its practical benefits but also validates its standing as an essential resource in modern engineering solutions. As industries continue to evolve, the demand for materials that offer efficiency without compromising ecological responsibilities will likely bolster the role of perforated aluminum mesh even further.

On the expertise front, professionals stress the importance of understanding the specific needs of each project when choosing the pattern and thickness of the mesh. Optimal airflow, for instance, can be achieved through precise perforation patterns, enhancing ventilation in spaces such as offices and factories. Similarly, in architectural facades, both the aesthetic value and the performance can be fine-tuned to achieve a specific visual impact while benefiting from natural lighting and heat control. The authoritativeness of using perforated aluminum mesh is further demonstrated in numerous successful case studies worldwide. Prestigious buildings, artistic installations, and state-of-the-art infrastructure projects often showcase its use, attesting to the material's reliability and appeal. Leaders in architecture and engineering frequently cite its role in modern design paradigms, emphasizing sustainability and innovative construction techniques. Trustworthiness is paramount in material selection, particularly regarding safety and compliance with environmental standards. Perforated aluminum mesh's recyclability is a significant advantage amid growing concerns over sustainability in construction practices. Aluminum's ability to be recycled without losing its properties aligns with global efforts to reduce carbon footprints, reinforcing its credibility as a sustainable choice for conscientious builders and designers. In conclusion, whether for achieving cutting-edge architectural aesthetics or meeting strict industrial specifications, perforated aluminum mesh stands out by merging functional superiority with design flexibility. Its successful deployment across a multitude of scenarios underscores not only its practical benefits but also validates its standing as an essential resource in modern engineering solutions. As industries continue to evolve, the demand for materials that offer efficiency without compromising ecological responsibilities will likely bolster the role of perforated aluminum mesh even further.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

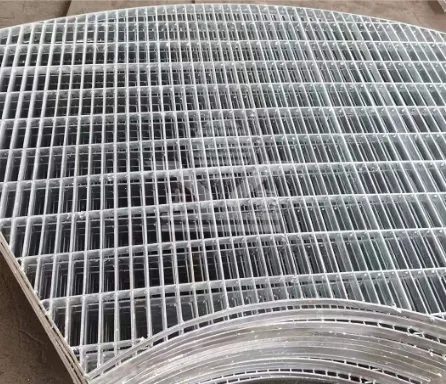

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP