2 月 . 12, 2025 22:34

Back to list

perforated aluminum panels

Perforated aluminum panels have become a prominent feature in modern architecture and design, prized for their versatility and contemporary aesthetic. These panels are not just a visual delight but are also crucial in creating functional spaces that enhance the architectural integrity of a building. Whether used in exterior facades, interior partitions, or ceilings, the role of perforated aluminum panels extends beyond mere decoration.

Moreover, the use of perforated aluminum panels is not limited to new constructions. They offer an effective solution for retrofitting existing structures where visual upgrades and enhanced functionality are desired without significant structural alterations. This retrofit potential underscores the panels’ versatility and ability to blend the old with the new in architectural designs. From an authoritative standpoint, manufacturers of perforated aluminum panels invest in research and development to innovate and improve product quality. These companies adhere to stringent industry standards and certifications to ensure the safety and performance of their products. Collaborating with reputable manufacturers provides architects and builders with the assurance of quality and reliability, reinforcing trust in the materials used. Furthermore, testimonies from projects worldwide serve as a testament to the reliability and aesthetic appeal of perforated aluminum panels. Case studies have shown their successful application in diverse settings—ranging from commercial buildings and residential projects to public spaces and industrial facilities—demonstrating their broad applicability. In conclusion, the incorporation of perforated aluminum panels is a strategic decision that combines aesthetic appeal with practical benefits. Their adaptability, combined with performance excellence, makes them a preferred choice for designers aiming to push the boundaries of modern architecture. As the trend towards sustainable and innovative design continues to grow, the role of perforated aluminum panels will undoubtedly remain pivotal, contributing both functionally and artistically to the built environment.

Moreover, the use of perforated aluminum panels is not limited to new constructions. They offer an effective solution for retrofitting existing structures where visual upgrades and enhanced functionality are desired without significant structural alterations. This retrofit potential underscores the panels’ versatility and ability to blend the old with the new in architectural designs. From an authoritative standpoint, manufacturers of perforated aluminum panels invest in research and development to innovate and improve product quality. These companies adhere to stringent industry standards and certifications to ensure the safety and performance of their products. Collaborating with reputable manufacturers provides architects and builders with the assurance of quality and reliability, reinforcing trust in the materials used. Furthermore, testimonies from projects worldwide serve as a testament to the reliability and aesthetic appeal of perforated aluminum panels. Case studies have shown their successful application in diverse settings—ranging from commercial buildings and residential projects to public spaces and industrial facilities—demonstrating their broad applicability. In conclusion, the incorporation of perforated aluminum panels is a strategic decision that combines aesthetic appeal with practical benefits. Their adaptability, combined with performance excellence, makes them a preferred choice for designers aiming to push the boundaries of modern architecture. As the trend towards sustainable and innovative design continues to grow, the role of perforated aluminum panels will undoubtedly remain pivotal, contributing both functionally and artistically to the built environment.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

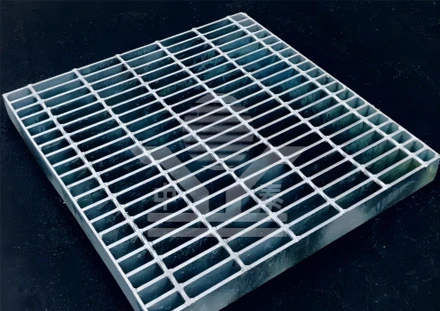

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP