2 月 . 06, 2025 06:29

Back to list

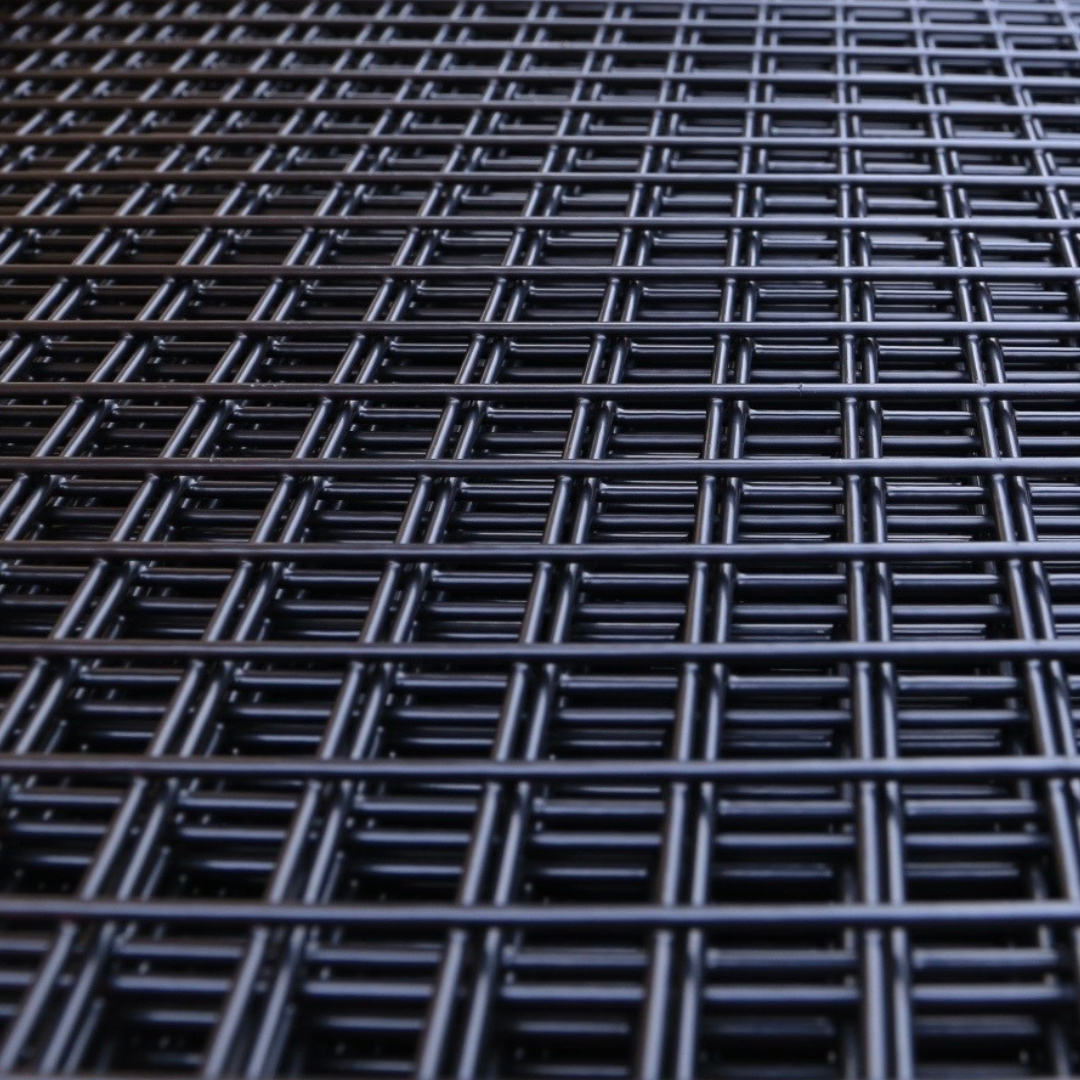

Punching Metal Mesh China Manufacturing Perforated Sheets PVC 0.2mm - 20mm Thickness Perforated Metal Sheet for Ceiling

The evolution of metal engineering has introduced a plethora of materials that cater to the diverse needs of modern industries. Among these, metal sheets with small holes, often referred to as perforated metal sheets, have emerged as a pivotal component across various sectors due to their versatility and functional benefits. As the landscape of industrial applications expands, understanding the unique attributes and applications of these materials is crucial for businesses aiming to leverage their full potential.

Security applications further highlight the importance of perforated metal sheets. In facilities where visibility must be balanced with secure environments, such as in facilities fencing, these sheets provide an excellent solution. They allow for supervision without compromising the structural integrity or safety of the facility, bridging the gap between functionality and security. The journey of choosing the right perforated metal sheet can be complex, given the myriad of options available. This is where expertise and authoritative guidance come into play. Working with experienced suppliers who understand material science and industrial demands can transform a high-level concept into a tangible, working solution. Such expertise ensures that factors like material selection, perforation pattern, and post-processing treatments are aligned with the specific requirements of a project. Trust is the core of investing in perforated metal sheets. Reputable manufacturers not only deliver quality products but also provide certifications and testing results that affirm the durability and compliance of the materials. This transparency lays the groundwork for a trustworthy relationship, instilling confidence in businesses to adopt these versatile metals in their projects. In conclusion, metal sheets with small holes are not just materials; they are a convergence of science, design, and function. Their wide range of applications across different industry sectors underscores their intrinsic value. As businesses and industries continue to evolve, embracing the innovations of perforated metal sheets will undoubtedly cater to the demands of both the present and future, ensuring sustainability, efficiency, and aesthetic appeal.

Security applications further highlight the importance of perforated metal sheets. In facilities where visibility must be balanced with secure environments, such as in facilities fencing, these sheets provide an excellent solution. They allow for supervision without compromising the structural integrity or safety of the facility, bridging the gap between functionality and security. The journey of choosing the right perforated metal sheet can be complex, given the myriad of options available. This is where expertise and authoritative guidance come into play. Working with experienced suppliers who understand material science and industrial demands can transform a high-level concept into a tangible, working solution. Such expertise ensures that factors like material selection, perforation pattern, and post-processing treatments are aligned with the specific requirements of a project. Trust is the core of investing in perforated metal sheets. Reputable manufacturers not only deliver quality products but also provide certifications and testing results that affirm the durability and compliance of the materials. This transparency lays the groundwork for a trustworthy relationship, instilling confidence in businesses to adopt these versatile metals in their projects. In conclusion, metal sheets with small holes are not just materials; they are a convergence of science, design, and function. Their wide range of applications across different industry sectors underscores their intrinsic value. As businesses and industries continue to evolve, embracing the innovations of perforated metal sheets will undoubtedly cater to the demands of both the present and future, ensuring sustainability, efficiency, and aesthetic appeal.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP