2 月 . 06, 2025 06:05

Back to list

Three peak wind dust net

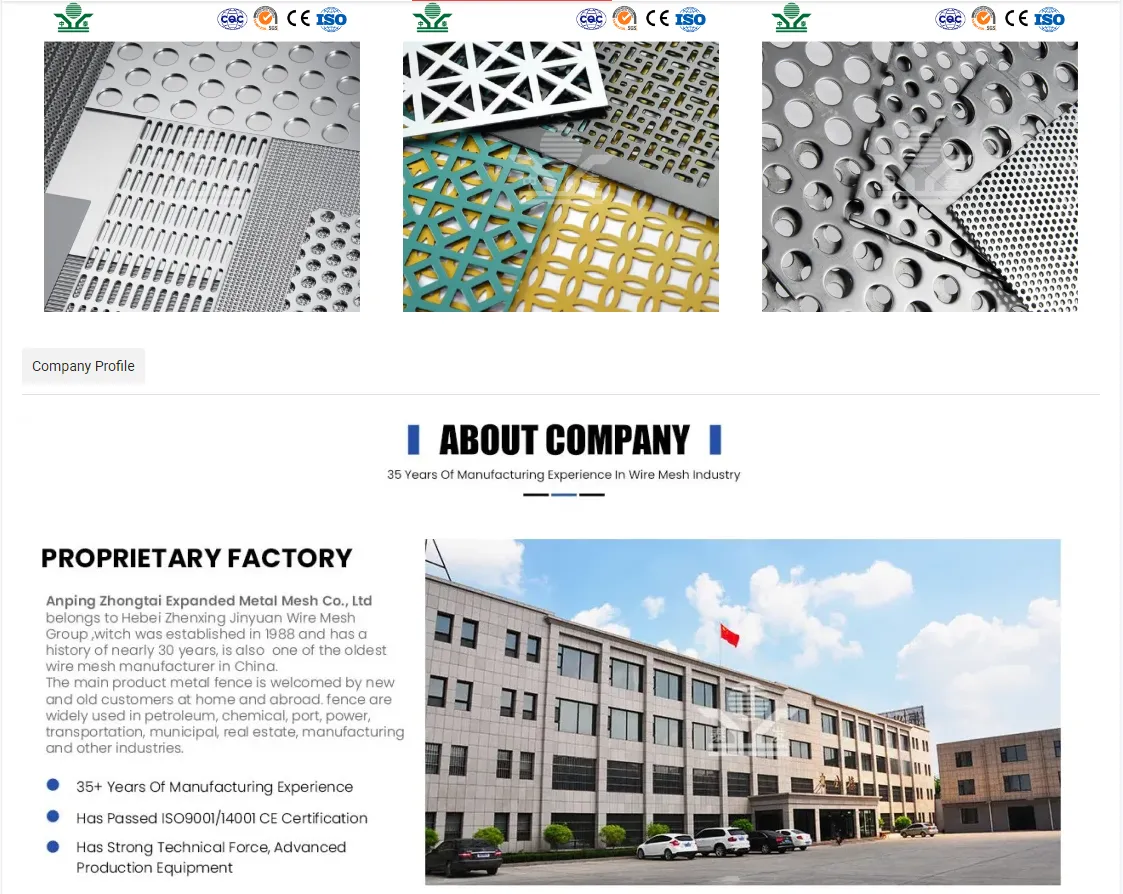

Metal sheets with square holes, commonly known as perforated metal sheets, stand as an indispensable resource across various industries, blending functionality with aesthetic appeal. Their versatility stems from the unique combination of durability, ventilation, and customization they offer, making them an ideal solution for both architectural and industrial applications.

Selecting the right perforated metal sheet involves assessing factors like hole size, material, and thickness, which are crucial to ensuring it meets the desired application. Thicker sheets provide added strength, which is important for heavy-duty applications, while thinner ones may be preferable for decorative uses where weight is a concern. Corrosion resistance is another critical consideration, particularly for outdoor or marine applications where stainless steel or galvanized options may be more appropriate. Beyond aesthetics and functionality, the environmental implications of choosing perforated metal sheets are noteworthy. These products are often manufactured from recyclable materials and sustain long-term use, reducing the need for frequent replacements. As industries increasingly strive towards greener practices, the eco-friendly nature of these metal sheets aligns with sustainability goals. To ensure optimal performance and longevity, regular maintenance of the metal sheets is advised. Simple measures such as routine cleaning and inspection can prevent build-up of dirt or potential corrosion, especially when used in harsh environments. Protective coatings and finishes are also available to enhance durability and preserve their appearance. In conclusion, metal sheets with square holes are not just a structural element, but a versatile solution adaptable to an array of industries. Their ability to combine function with aesthetic appeal, while offering customizability and sustainability, confirms their place as an intelligent choice for contemporary design and industrial applications. As innovations in material science and manufacturing continue to advance, the potential applications for these perforated sheets are bound to expand, offering even more solutions for creative and practical challenges.

Selecting the right perforated metal sheet involves assessing factors like hole size, material, and thickness, which are crucial to ensuring it meets the desired application. Thicker sheets provide added strength, which is important for heavy-duty applications, while thinner ones may be preferable for decorative uses where weight is a concern. Corrosion resistance is another critical consideration, particularly for outdoor or marine applications where stainless steel or galvanized options may be more appropriate. Beyond aesthetics and functionality, the environmental implications of choosing perforated metal sheets are noteworthy. These products are often manufactured from recyclable materials and sustain long-term use, reducing the need for frequent replacements. As industries increasingly strive towards greener practices, the eco-friendly nature of these metal sheets aligns with sustainability goals. To ensure optimal performance and longevity, regular maintenance of the metal sheets is advised. Simple measures such as routine cleaning and inspection can prevent build-up of dirt or potential corrosion, especially when used in harsh environments. Protective coatings and finishes are also available to enhance durability and preserve their appearance. In conclusion, metal sheets with square holes are not just a structural element, but a versatile solution adaptable to an array of industries. Their ability to combine function with aesthetic appeal, while offering customizability and sustainability, confirms their place as an intelligent choice for contemporary design and industrial applications. As innovations in material science and manufacturing continue to advance, the potential applications for these perforated sheets are bound to expand, offering even more solutions for creative and practical challenges.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP