1 月 . 26, 2025 03:48

Back to list

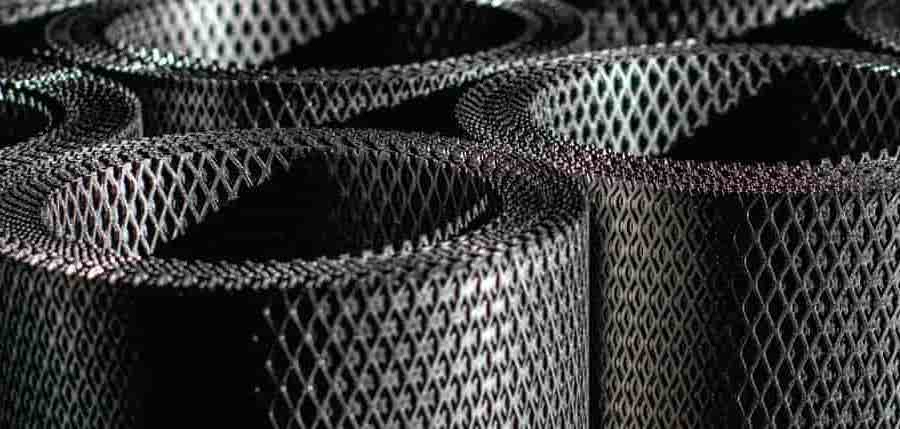

metal mesh grating

Metal mesh grating has become an indispensable component across various industries due to its versatile applications and robust characteristics. Understanding the comprehensive benefits and the intricate details that underlie its functionality can provide invaluable insight for businesses considering its integration. This article delves into the intricacies of metal mesh grating, emphasizing the essential features that distinguish it from other materials, its industrial applications, and the factors to consider when selecting the right type for specific needs.

The adaptability of metal mesh grating in customized designs also ensures that it can meet specific operational needs. Grating can be tailored in terms of dimensions, load ratings, and finishes to cater to unique industrial requirements. The ability to customize these factors highlights the expertise ingrained in the production and application of metal mesh grating, providing assurance of its performance across diverse scenarios. When selecting metal mesh grating, it is pivotal to consider load requirements, environmental conditions, and compliance with industry safety standards. These factors should guide the choice of metal type, design, and finishing processes. The selection process also demands an understanding of the precise application and the nature of the traffic or usage it will endure. Consultations with industry experts or detailed examinations of past case studies can assist in making informed decisions, fortifying the selection process with authoritative insights. The credibility of metal mesh grating as a reliable construction material is further augmented by its longstanding use in high-stakes environments such as oil rigs and urban infrastructure projects. Its established reputation for satisfying stringent safety criteria and enduring intense operational conditions marks it as a trustworthy option. Companies should strive to source material from manufacturers whose quality assurances are validated by international standards, ensuring a high trust factor in its utilization. In summation, the introduction of metal mesh grating into various industrial processes underscores its authoritative presence as a structural solution. Its expert engineering, adaptability, and proven trustworthiness make it an exemplary choice for industries seeking to optimize their environments for safety and efficiency. By conducting thorough evaluations and leveraging professional insights, businesses can capitalize on the myriad benefits of metal mesh grating, enhancing their capabilities and supporting their long-term operational goals.

The adaptability of metal mesh grating in customized designs also ensures that it can meet specific operational needs. Grating can be tailored in terms of dimensions, load ratings, and finishes to cater to unique industrial requirements. The ability to customize these factors highlights the expertise ingrained in the production and application of metal mesh grating, providing assurance of its performance across diverse scenarios. When selecting metal mesh grating, it is pivotal to consider load requirements, environmental conditions, and compliance with industry safety standards. These factors should guide the choice of metal type, design, and finishing processes. The selection process also demands an understanding of the precise application and the nature of the traffic or usage it will endure. Consultations with industry experts or detailed examinations of past case studies can assist in making informed decisions, fortifying the selection process with authoritative insights. The credibility of metal mesh grating as a reliable construction material is further augmented by its longstanding use in high-stakes environments such as oil rigs and urban infrastructure projects. Its established reputation for satisfying stringent safety criteria and enduring intense operational conditions marks it as a trustworthy option. Companies should strive to source material from manufacturers whose quality assurances are validated by international standards, ensuring a high trust factor in its utilization. In summation, the introduction of metal mesh grating into various industrial processes underscores its authoritative presence as a structural solution. Its expert engineering, adaptability, and proven trustworthiness make it an exemplary choice for industries seeking to optimize their environments for safety and efficiency. By conducting thorough evaluations and leveraging professional insights, businesses can capitalize on the myriad benefits of metal mesh grating, enhancing their capabilities and supporting their long-term operational goals.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP