1 月 . 26, 2025 03:27

Back to list

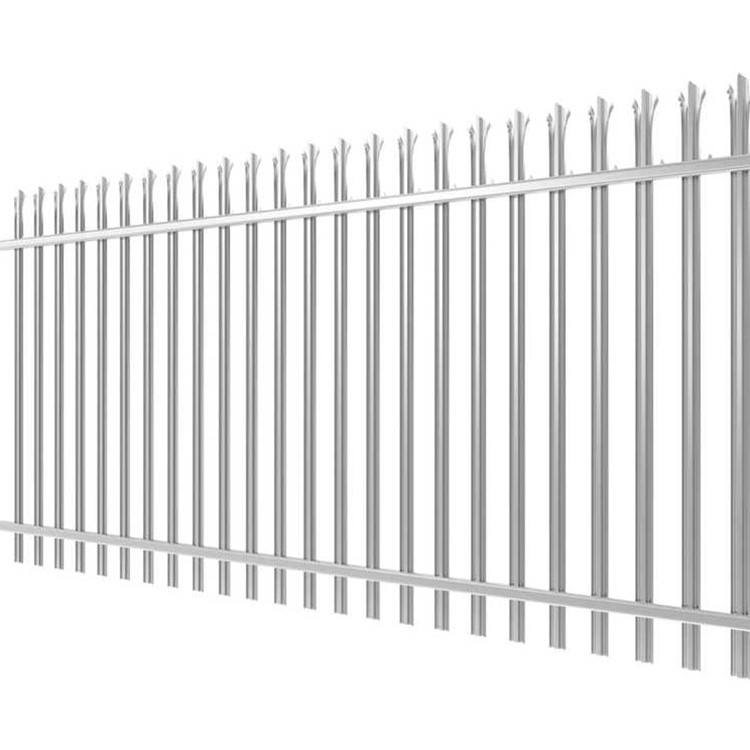

3D Galvanized Steel Material Perforated Metal Sheet for Fencing

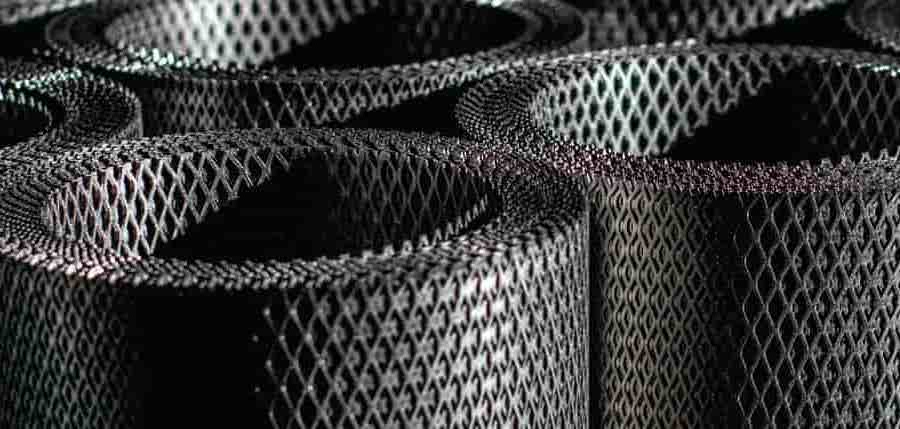

Light duty grating, a versatile solution widely used in various industries, is experiencing growing demand due to its lightweight characteristics and broad applications. Unlike traditional grating, light duty grating is designed to withstand minimal to moderate loads, making it a cost-effective option for specific projects while introducing ease of installation and handling. Understanding its benefits, applications, and how to choose the right type can make a significant difference in project outcomes.

Reliable manufacturers are fundamental to sourcing high-quality light duty grating. Partnering with established suppliers enhances project integrity, offering products that meet industry standards and project specifications. Experienced manufacturers offer comprehensive guidance on product choice, considering factors such as load bearing capacity, durability requirements, and compliance with safety regulations. Moreover, light duty grating is environmentally friendly, often produced from recycled materials, aligning with growing sustainability goals. Choosing eco-friendly options not only supports environmental initiatives but often yields long-term economic advantages. Products manufactured with recycled content benefit from reduced material costs and contribute to sustainable building certifications, meeting an increasing demand from stakeholders and regulatory bodies for resource-efficient construction. Purchasing light duty grating is an investment that requires careful planning and consideration. Ensuring the chosen solution aligns with the overarching goals of the project demands a thorough assessment, from material choice to manufacturer reliability. The low-maintenance attributes of light duty grating further underline its cost-effectiveness, saving both time and resources over its lifespan. To summarize, selecting light duty grating involves a comprehensive understanding of its diverse applications, material options, and associated benefits. Its ability to deliver on both functional and aesthetic fronts makes it a superb choice for a variety of projects. The integration of light duty grating into a project reflects a balance of expertise, practicality, and sustainable practice. As industries continue to evolve, adopting solutions that achieve optimal performance while being resource-efficient is more crucial than ever, with light duty grating demonstrating exactly such capabilities.

Reliable manufacturers are fundamental to sourcing high-quality light duty grating. Partnering with established suppliers enhances project integrity, offering products that meet industry standards and project specifications. Experienced manufacturers offer comprehensive guidance on product choice, considering factors such as load bearing capacity, durability requirements, and compliance with safety regulations. Moreover, light duty grating is environmentally friendly, often produced from recycled materials, aligning with growing sustainability goals. Choosing eco-friendly options not only supports environmental initiatives but often yields long-term economic advantages. Products manufactured with recycled content benefit from reduced material costs and contribute to sustainable building certifications, meeting an increasing demand from stakeholders and regulatory bodies for resource-efficient construction. Purchasing light duty grating is an investment that requires careful planning and consideration. Ensuring the chosen solution aligns with the overarching goals of the project demands a thorough assessment, from material choice to manufacturer reliability. The low-maintenance attributes of light duty grating further underline its cost-effectiveness, saving both time and resources over its lifespan. To summarize, selecting light duty grating involves a comprehensive understanding of its diverse applications, material options, and associated benefits. Its ability to deliver on both functional and aesthetic fronts makes it a superb choice for a variety of projects. The integration of light duty grating into a project reflects a balance of expertise, practicality, and sustainable practice. As industries continue to evolve, adopting solutions that achieve optimal performance while being resource-efficient is more crucial than ever, with light duty grating demonstrating exactly such capabilities.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP