1 月 . 26, 2025 03:06

Back to list

Hexagonal Wire Mesh Gabion China Suppliers Retaining Wall Gabion 2.0 - 4.0 mm Wire Gauge PVC Coated Gabion

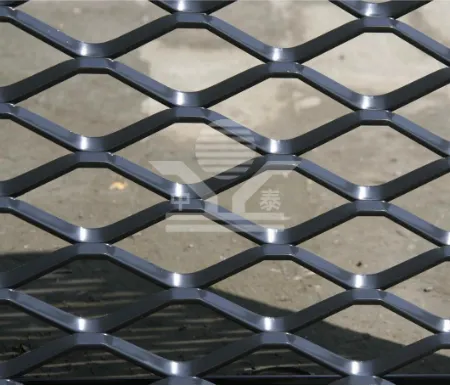

Industrial metal grating serves as a foundational element in numerous construction and industrial applications, propelling industries toward better efficiency and safety. With its distinctive capability to provide both structural integrity and aesthetic appeal, metal grating has carved a niche that combines practicality with versatility. Unpacking the facets of industrial metal grating underscores its pivotal role in a wide range of sectors.

Experts in the field consistently recommend periodic maintenance checks on industrial metal grating to ensure longevity and optimal performance. Regular inspections not only help in identifying any potential weak spots but also in planning out necessary repairs, thereby preventing any operational downtime that could result from unexpected failures. Employing knowledgeable personnel for these inspections is critical to accurately assess the condition of the grating and foster a sense of security among workers and stakeholders alike. Choosing the right supplier too contributes greatly to the effectiveness of metal grating installations. Leading suppliers often offer customization options, allowing for grating designs tailored to specific operational needs. Such suppliers typically boast a portfolio of diverse projects, reinforcing their authority and reliability in delivering high-quality gratings that adhere to industry standards. Trust also plays a significant role when considering industrial metal grating. Industries often cite testimonials and case studies highlighting successful applications and long-term benefits. These narratives provide assurance and build trust in the performance capabilities of metal grating, fostering a culture of safety and reliability within organizations. To sum up, industrial metal grating is more than just a construction component; it is an essential element that supports safety, functionality, and aesthetics in various applications. The expertise in selecting the appropriate material and design, combined with authoritative insights from industry leaders, ensures that metal grating continues to be a trusted and indispensable resource across multiple sectors. Its enduring presence and evolution demonstrate not only its immediate benefits but also its potential to meet future industrial challenges.

Experts in the field consistently recommend periodic maintenance checks on industrial metal grating to ensure longevity and optimal performance. Regular inspections not only help in identifying any potential weak spots but also in planning out necessary repairs, thereby preventing any operational downtime that could result from unexpected failures. Employing knowledgeable personnel for these inspections is critical to accurately assess the condition of the grating and foster a sense of security among workers and stakeholders alike. Choosing the right supplier too contributes greatly to the effectiveness of metal grating installations. Leading suppliers often offer customization options, allowing for grating designs tailored to specific operational needs. Such suppliers typically boast a portfolio of diverse projects, reinforcing their authority and reliability in delivering high-quality gratings that adhere to industry standards. Trust also plays a significant role when considering industrial metal grating. Industries often cite testimonials and case studies highlighting successful applications and long-term benefits. These narratives provide assurance and build trust in the performance capabilities of metal grating, fostering a culture of safety and reliability within organizations. To sum up, industrial metal grating is more than just a construction component; it is an essential element that supports safety, functionality, and aesthetics in various applications. The expertise in selecting the appropriate material and design, combined with authoritative insights from industry leaders, ensures that metal grating continues to be a trusted and indispensable resource across multiple sectors. Its enduring presence and evolution demonstrate not only its immediate benefits but also its potential to meet future industrial challenges.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP