2 月 . 02, 2025 01:36

Back to list

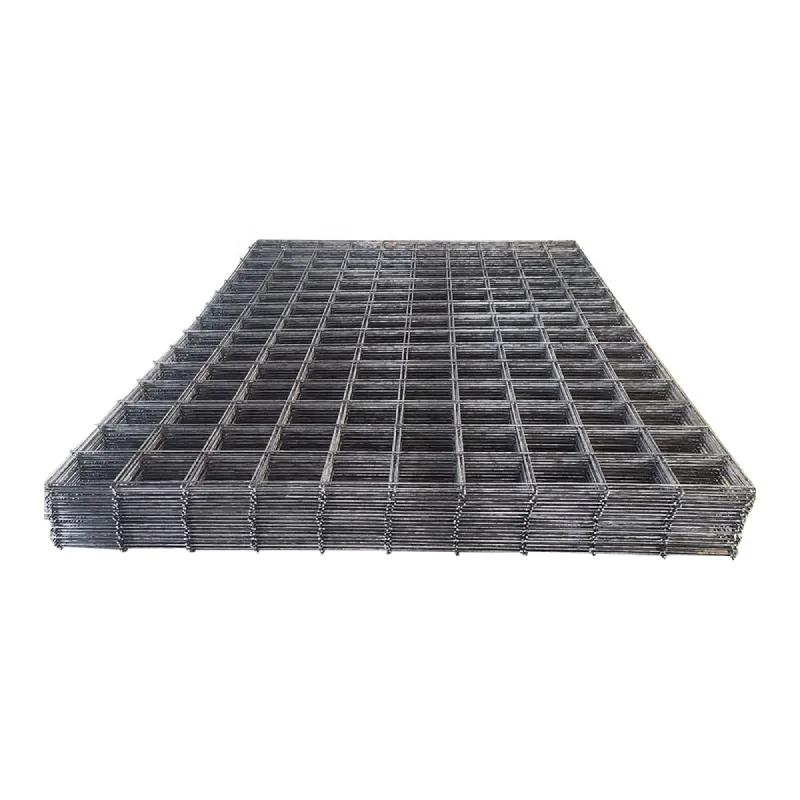

hdg steel grating

HDG steel grating, or hot-dip galvanized steel grating, stands as a testament to modern engineering and manufacturing prowess. Its application spans a wide range of industries, driven by a unique combination of durability, versatility, and cost-effectiveness. My extensive experience with HDG steel grating has provided me with valuable insights into why it is the preferred choice for projects demanding resilience and reliability.

Trustworthiness is augmented by the stringent manufacturing standards governing HDG steel grating production. Compliance with international standards such as ASTM A123/A123M—the standard specification for zinc coatings—ensures quality and consistency. Furthermore, the lifecycle cost efficiency of HDG steel grating contributes to its trustworthiness. While initial investment in hot-dip galvanized products might be higher compared to non-treated alternatives, the long-term savings in maintenance and replacements are substantial. Over decades-long timelines, the reduced need for repair or replacement translates to significant cost savings—a vital consideration for budget-conscious projects. Finally, the environmental sustainability of HDG steel grating cannot be overlooked. The materials used in its production are often recyclable, aligning with global trends towards sustainable construction practices. The longevity of HDG steel grating also plays a role in minimizing resource use over time, as fewer materials are required for maintenance and replacement. Throughout my career, practical engagements with HDG steel grating have reinforced my understanding of its unparalleled advantages. Positions that demand high levels of reliability, from expansive industrial complexes to local municipal projects, routinely benefit from incorporating this robust material. By selecting HDG steel grating, stakeholders ensure not only immediate performance but also long-term economic and environmental benefits. For those seeking credible, expert insights into optimizing infrastructure durability and safety, HDG steel grating remains a definitive choice.

Trustworthiness is augmented by the stringent manufacturing standards governing HDG steel grating production. Compliance with international standards such as ASTM A123/A123M—the standard specification for zinc coatings—ensures quality and consistency. Furthermore, the lifecycle cost efficiency of HDG steel grating contributes to its trustworthiness. While initial investment in hot-dip galvanized products might be higher compared to non-treated alternatives, the long-term savings in maintenance and replacements are substantial. Over decades-long timelines, the reduced need for repair or replacement translates to significant cost savings—a vital consideration for budget-conscious projects. Finally, the environmental sustainability of HDG steel grating cannot be overlooked. The materials used in its production are often recyclable, aligning with global trends towards sustainable construction practices. The longevity of HDG steel grating also plays a role in minimizing resource use over time, as fewer materials are required for maintenance and replacement. Throughout my career, practical engagements with HDG steel grating have reinforced my understanding of its unparalleled advantages. Positions that demand high levels of reliability, from expansive industrial complexes to local municipal projects, routinely benefit from incorporating this robust material. By selecting HDG steel grating, stakeholders ensure not only immediate performance but also long-term economic and environmental benefits. For those seeking credible, expert insights into optimizing infrastructure durability and safety, HDG steel grating remains a definitive choice.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP