2 月 . 02, 2025 01:18

Back to list

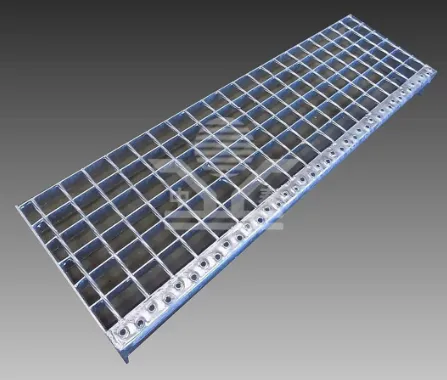

hot dip galvanized steel grating

Hot dip galvanized steel grating is a product that has revolutionized various industries with its unparalleled durability and versatility. With decades of application experience, experts have continually praised its reliability in a wide spectrum of environments. This article delves into what makes hot dip galvanized steel grating a standout choice for industrial and commercial uses, and why it’s become a credible option for sustainable engineering solutions.

The authoritativeness of hot dip galvanized steel grating is evident in its specification by numerous industry standards worldwide. Recognized by bodies such as ISO and ASTM, the rigorous testing and compliance requirements this product meets ensure its quality and performance. Various reports and industrial papers consistently highlight the unparalleled resistance to abrasion and chemical leaching afforded by the zinc coating. Trusted across sectors, from petrochemical facilities to food processing plants, this grating allows for safe, hygienic, and efficient operations. Finally, trustworthiness is perhaps the greatest testament to hot dip galvanized steel grating’s standing in the market. The material's traceability and adherence to stringent manufacturing protocols provide users with confidence in its performance. Manufacturers often offer long warranties and will provide lifecycle analyses, underscoring their commitment to quality and longevity. The predictability and consistency in how the grating performs under stress fully embody trustworthiness. In summary, the choice of hot dip galvanized steel grating offers unmatched reliability backed by extensive research and field application. Its durability, expert application, authoritative endorsements, and trustworthy performance make it a distinguished material. Given its proven track record in a host of demanding environments, it is poised as a front-runner in evolving industries, continually setting standards for safety, efficiency, and sustainability. Investing in hot dip galvanized steel grating means investing in a future-ready solution that stands up to nature and the demands of modern infrastructure.

The authoritativeness of hot dip galvanized steel grating is evident in its specification by numerous industry standards worldwide. Recognized by bodies such as ISO and ASTM, the rigorous testing and compliance requirements this product meets ensure its quality and performance. Various reports and industrial papers consistently highlight the unparalleled resistance to abrasion and chemical leaching afforded by the zinc coating. Trusted across sectors, from petrochemical facilities to food processing plants, this grating allows for safe, hygienic, and efficient operations. Finally, trustworthiness is perhaps the greatest testament to hot dip galvanized steel grating’s standing in the market. The material's traceability and adherence to stringent manufacturing protocols provide users with confidence in its performance. Manufacturers often offer long warranties and will provide lifecycle analyses, underscoring their commitment to quality and longevity. The predictability and consistency in how the grating performs under stress fully embody trustworthiness. In summary, the choice of hot dip galvanized steel grating offers unmatched reliability backed by extensive research and field application. Its durability, expert application, authoritative endorsements, and trustworthy performance make it a distinguished material. Given its proven track record in a host of demanding environments, it is poised as a front-runner in evolving industries, continually setting standards for safety, efficiency, and sustainability. Investing in hot dip galvanized steel grating means investing in a future-ready solution that stands up to nature and the demands of modern infrastructure.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP