1 月 . 26, 2025 00:50

Back to list

Chain Link Barbed Wire China Manufacturing 300mm Coil Diameter Flat Barbed Wire Used for White Security Fence

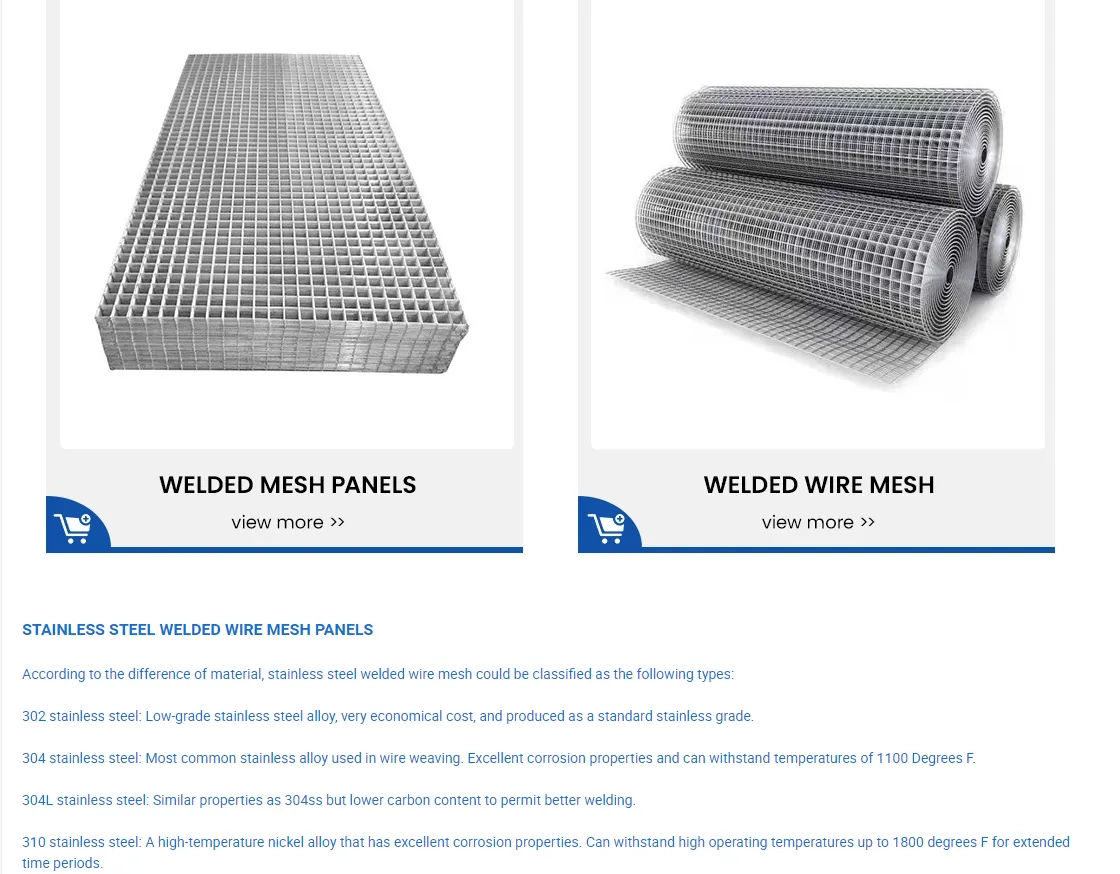

Grating galvanized steel represents a linchpin component across various industrial applications, marrying the fundamental attributes of strength, durability, and corrosion resistance. In a market that demands ever-improving materials, galvanized steel grating has established itself as a preferred choice for engineers and builders seeking reliability coupled with long-lasting performance.

Building trust in material choice is imperative, and galvanized steel grating delivers in spades. Clients and contractors can rely on the transparency and predictability of performance it offers. The manufacturing process of galvanization is heavily regulated, ensuring consistent quality. Standards such as ASTM (American Society for Testing and Materials) provide a framework of excellence that galvanized products must meet, giving buyers confidence in their investment. In terms of sustainability and eco-friendliness, galvanized steel grating doesn’t fall short. The entire process of galvanizing and subsequent use is environmentally benign, with the zinc itself being fully recyclable. Incorporating galvanized steel in construction projects therefore supports sustainability goals, a key consideration in modern industrial and civil engineering environments. Lastly, galvanized steel grating sets itself apart with an aesthetic edge. The bright appearance of freshly galvanized steel has an attractive finish that enhances its visual appeal in architectural projects. While it is fundamentally a functional material, its appearance means it can be effectively integrated into environments where aesthetics are as important as utility. In summary, galvanized steel grating offers a comprehensive solution for industries requiring a high degree of safety, reliability, and durability. Its proven performance across diverse conditions, backed by expert testimonials and authoritative research, positions it as a superior material that secures stakeholder trust. As sustainability and performance continue to drive choices in construction materials, galvanized steel grating will undoubtedly remain at the forefront, its unmatched attributes acting as a beacon of industrial progress.

Building trust in material choice is imperative, and galvanized steel grating delivers in spades. Clients and contractors can rely on the transparency and predictability of performance it offers. The manufacturing process of galvanization is heavily regulated, ensuring consistent quality. Standards such as ASTM (American Society for Testing and Materials) provide a framework of excellence that galvanized products must meet, giving buyers confidence in their investment. In terms of sustainability and eco-friendliness, galvanized steel grating doesn’t fall short. The entire process of galvanizing and subsequent use is environmentally benign, with the zinc itself being fully recyclable. Incorporating galvanized steel in construction projects therefore supports sustainability goals, a key consideration in modern industrial and civil engineering environments. Lastly, galvanized steel grating sets itself apart with an aesthetic edge. The bright appearance of freshly galvanized steel has an attractive finish that enhances its visual appeal in architectural projects. While it is fundamentally a functional material, its appearance means it can be effectively integrated into environments where aesthetics are as important as utility. In summary, galvanized steel grating offers a comprehensive solution for industries requiring a high degree of safety, reliability, and durability. Its proven performance across diverse conditions, backed by expert testimonials and authoritative research, positions it as a superior material that secures stakeholder trust. As sustainability and performance continue to drive choices in construction materials, galvanized steel grating will undoubtedly remain at the forefront, its unmatched attributes acting as a beacon of industrial progress.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP