1 月 . 26, 2025 00:28

Back to list

Single peak wind dust net

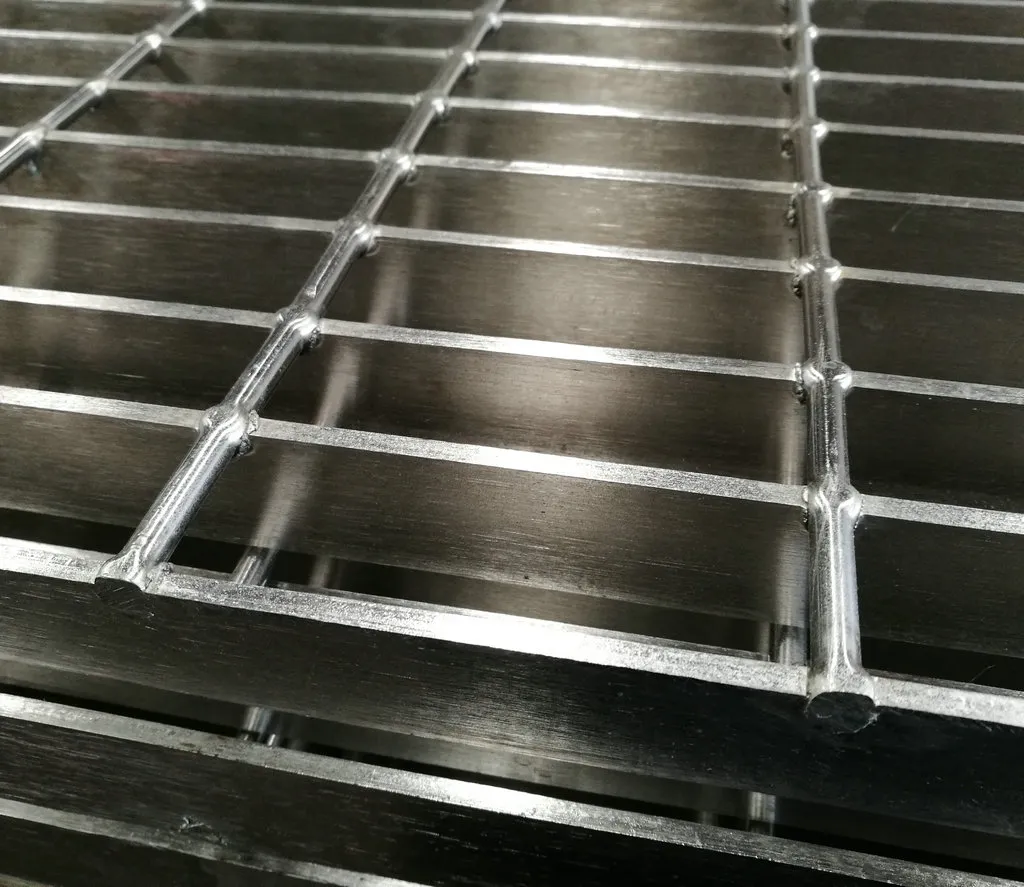

Understanding the significance of a grated metal floor in industrial and commercial environments is crucial for maintaining safety and efficiency. Grated metal floors are often indispensable components in construction projects, valued for their robustness and versatility. They serve multiple purposes, including ensuring safe pedestrian traffic, facilitating drainage, and providing traction in slippery conditions.

Customization is another appealing feature of grated metal floors. Manufacturers can tailor products to specific requirements, whether that entails unique surface textures to enhance grip or specific load-bearing capacities to support heavy machinery. This adaptability ensures that grated metal floors can meet the diverse needs of various industries, from oil and gas to automotive manufacturing. Installation and maintenance of grated metal floors are relatively straightforward, further enhancing their appeal. Installation generally involves fitting pre-fabricated panels or sections into the designated area, a process that can often be completed with minimal disruption to ongoing operations. As for maintenance, regular inspections and cleaning suffice to preserve the integrity and performance of grated metal floors, ensuring they continue to provide safe, efficient service for years. Choosing the right grated metal floor requires consideration of several factors, including the environment in which it will be used, the types of materials passing over it, and the weight-bearing requirements. Consulting with experts in the field can guide decision-makers in selecting a product that not only meets industry safety standards but also aligns with the operational goals of the facility. In summary, grated metal floors offer a blend of safety, durability, and adaptability, making them an ideal choice in a wide range of industrial applications. Their ability to enhance workplace safety and operational efficiency, combined with the cost-effectiveness of a long-lasting product, establishes them as a critical component in the industrial and commercial landscape. Prioritizing these floors is a testament to a company’s commitment to quality, safety, and long-term productivity.

Customization is another appealing feature of grated metal floors. Manufacturers can tailor products to specific requirements, whether that entails unique surface textures to enhance grip or specific load-bearing capacities to support heavy machinery. This adaptability ensures that grated metal floors can meet the diverse needs of various industries, from oil and gas to automotive manufacturing. Installation and maintenance of grated metal floors are relatively straightforward, further enhancing their appeal. Installation generally involves fitting pre-fabricated panels or sections into the designated area, a process that can often be completed with minimal disruption to ongoing operations. As for maintenance, regular inspections and cleaning suffice to preserve the integrity and performance of grated metal floors, ensuring they continue to provide safe, efficient service for years. Choosing the right grated metal floor requires consideration of several factors, including the environment in which it will be used, the types of materials passing over it, and the weight-bearing requirements. Consulting with experts in the field can guide decision-makers in selecting a product that not only meets industry safety standards but also aligns with the operational goals of the facility. In summary, grated metal floors offer a blend of safety, durability, and adaptability, making them an ideal choice in a wide range of industrial applications. Their ability to enhance workplace safety and operational efficiency, combined with the cost-effectiveness of a long-lasting product, establishes them as a critical component in the industrial and commercial landscape. Prioritizing these floors is a testament to a company’s commitment to quality, safety, and long-term productivity.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP