2 月 . 13, 2025 04:50

Back to list

Stainless steel wire netting

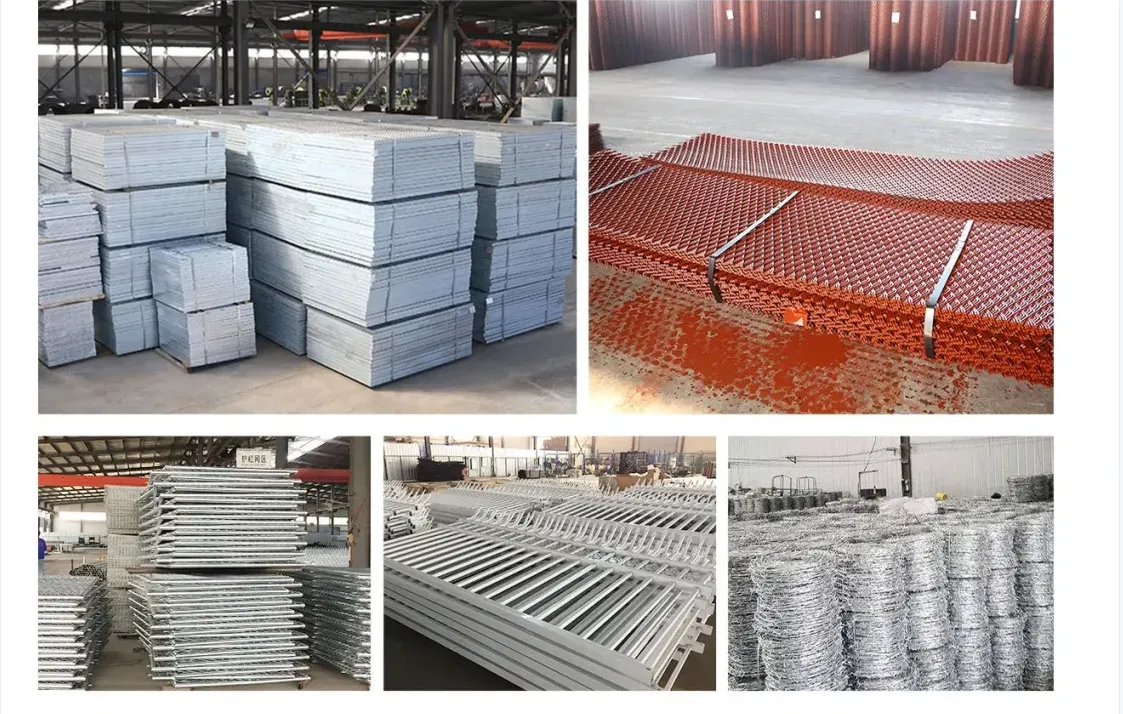

Quality construction and innovative design rely heavily on materials that are both durable and adaptable. One such material that has gained immense popularity in both industrial and residential projects is the galvanised perforated metal sheet. When evaluating the myriad of construction and design materials available, choosing the right one can make an enormous difference in terms of longevity, functionality, and aesthetics. Galvanised perforated metal sheets provide all these benefits, making them a highly recommended choice for a range of applications.

Trust in galvanized perforated metal sheets is rooted in their proven reliability and the long-standing history of their usage across diverse industries. For instance, they have played an integral role in automotive manufacturing, agriculture, food processing, and architecture. The consistency with which these sheets deliver high performance is backed by rigorous industry standards and tests, ensuring that they can withstand various environmental conditions and retain their structural integrity. Real-world experiences further validate their practicality and enduring performance. Users from various industrial sectors have consistently reported significant improvements after integrating galvanised perforated metal sheets into their systems. These testimonials, coupled with empirical data, reinforce their status as a preferred material choice. For example, factories utilizing these sheets in ventilation systems have noted enhanced air flow control, while agricultural applications have seen improved resilience in hostile weather conditions. In terms of authoritativeness, no discussion of galvanised perforated metal sheets could be complete without mentioning the reputable manufacturers and innovators pushing the boundaries of what these products can offer. Many industry leaders invest heavily in research and development to refine manufacturing processes, improve coating technologies, and expand application possibilities. Such advances not only increase the potential uses of perforated sheets but also ensure compliance with environmental and safety standards, solidifying their place in sustainable construction practices. Ultimately, the importance of selecting high-quality galvanised perforated metal sheets lies in their blend of innovation, durability, and adaptability. They represent a versatile and reliable solution for numerous challenges faced in construction and design projects. Embracing this material not only enhances the functionality and longevity of constructions but also invites novel design possibilities, proving invaluable to both industry experts and project visionaries alike.

Trust in galvanized perforated metal sheets is rooted in their proven reliability and the long-standing history of their usage across diverse industries. For instance, they have played an integral role in automotive manufacturing, agriculture, food processing, and architecture. The consistency with which these sheets deliver high performance is backed by rigorous industry standards and tests, ensuring that they can withstand various environmental conditions and retain their structural integrity. Real-world experiences further validate their practicality and enduring performance. Users from various industrial sectors have consistently reported significant improvements after integrating galvanised perforated metal sheets into their systems. These testimonials, coupled with empirical data, reinforce their status as a preferred material choice. For example, factories utilizing these sheets in ventilation systems have noted enhanced air flow control, while agricultural applications have seen improved resilience in hostile weather conditions. In terms of authoritativeness, no discussion of galvanised perforated metal sheets could be complete without mentioning the reputable manufacturers and innovators pushing the boundaries of what these products can offer. Many industry leaders invest heavily in research and development to refine manufacturing processes, improve coating technologies, and expand application possibilities. Such advances not only increase the potential uses of perforated sheets but also ensure compliance with environmental and safety standards, solidifying their place in sustainable construction practices. Ultimately, the importance of selecting high-quality galvanised perforated metal sheets lies in their blend of innovation, durability, and adaptability. They represent a versatile and reliable solution for numerous challenges faced in construction and design projects. Embracing this material not only enhances the functionality and longevity of constructions but also invites novel design possibilities, proving invaluable to both industry experts and project visionaries alike.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP