2 月 . 13, 2025 04:18

Back to list

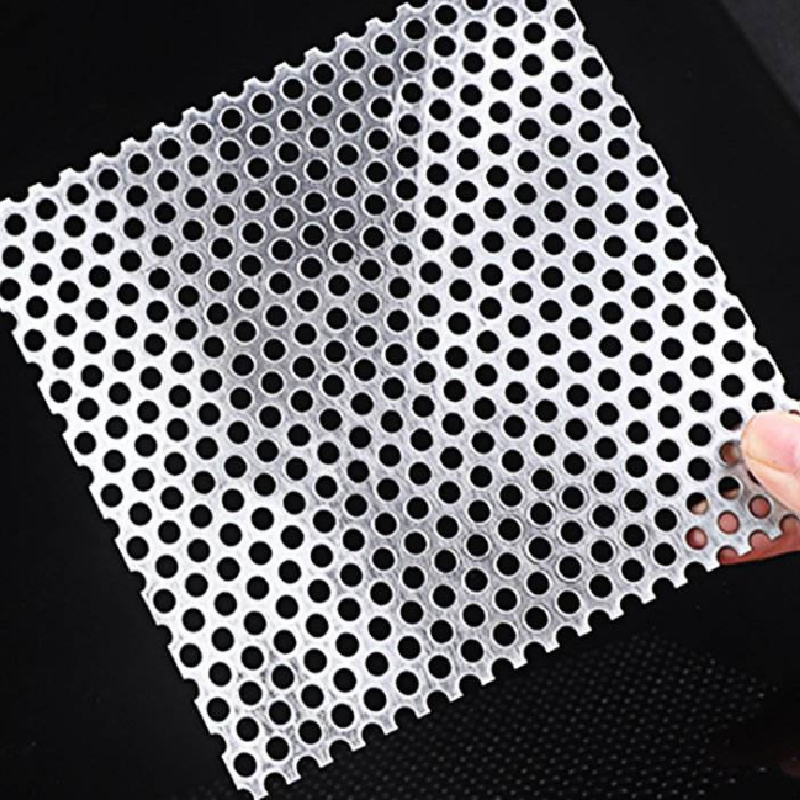

Zhongtai Oval Hole Perforated Metal China Factory 0.8mm Perforated Sheet Metal

Galvanized perforated metal is an indispensable material in numerous industries, revered for its unique combination of strength, versatility, and aesthetic appeal. This remarkable material is crafted by punching holes into galvanized sheets of metal, resulting in a product that exhibits exceptional properties, such as enhanced durability and corrosion resistance. The galvanized coating serves as a protective layer that shields the metal from rust and environmental wear, making it ideal for both indoor and outdoor applications.

Expertly manufactured to meet strict standards, galvanized perforated metal exemplifies engineering precision. The manufacturing process adheres to rigorous quality control measures that ensure uniformity and precision across all perforations. This attention to detail not only enhances the structural integrity of the material but also assures users of its reliability and performance. In terms of trustworthiness, opting for reputable suppliers ensures that buyers receive authentic, high-quality galvanized perforated metal. Leading manufacturers provide assurance of quality through compliance with industry standards and stringent testing protocols. This commitment to quality reflects not only in the product lifespan but also in its safety, making it a reliable component in construction and industrial applications. With the increasing demand for sustainable building materials, galvanized perforated metal steps into the limelight as an environmentally responsible choice. Its recyclability and the efficiency of its manufacturing processes contribute significantly to reduced environmental impact. Choosing this material supports sustainable building practices and aligns with global initiatives aimed at reducing carbon footprints. In conclusion, galvanized perforated metal stands as a paragon of modern engineering, intertwining durability, versatility, and aesthetic appeal. Its adaptability across various applications confirms its status as an invaluable asset in numerous industries, while its excellent resistance to environmental factors amplifies its cost-effectiveness. The trust and reliability accompanying high-quality galvanized perforated metal echo the dedication of manufacturers who prioritize excellence and sustainability. For industries and applications seeking a material that harmonizes strength with aesthetic flexibility, galvanized perforated metal emerges as an unrivaled choice.

Expertly manufactured to meet strict standards, galvanized perforated metal exemplifies engineering precision. The manufacturing process adheres to rigorous quality control measures that ensure uniformity and precision across all perforations. This attention to detail not only enhances the structural integrity of the material but also assures users of its reliability and performance. In terms of trustworthiness, opting for reputable suppliers ensures that buyers receive authentic, high-quality galvanized perforated metal. Leading manufacturers provide assurance of quality through compliance with industry standards and stringent testing protocols. This commitment to quality reflects not only in the product lifespan but also in its safety, making it a reliable component in construction and industrial applications. With the increasing demand for sustainable building materials, galvanized perforated metal steps into the limelight as an environmentally responsible choice. Its recyclability and the efficiency of its manufacturing processes contribute significantly to reduced environmental impact. Choosing this material supports sustainable building practices and aligns with global initiatives aimed at reducing carbon footprints. In conclusion, galvanized perforated metal stands as a paragon of modern engineering, intertwining durability, versatility, and aesthetic appeal. Its adaptability across various applications confirms its status as an invaluable asset in numerous industries, while its excellent resistance to environmental factors amplifies its cost-effectiveness. The trust and reliability accompanying high-quality galvanized perforated metal echo the dedication of manufacturers who prioritize excellence and sustainability. For industries and applications seeking a material that harmonizes strength with aesthetic flexibility, galvanized perforated metal emerges as an unrivaled choice.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP