1 月 . 29, 2025 03:09

Back to list

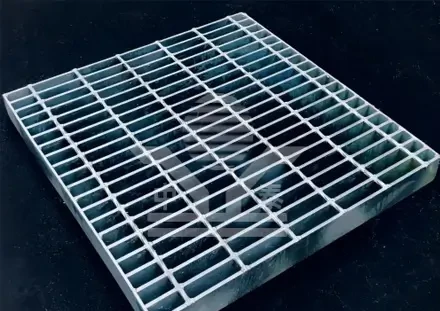

steel grating thickness

Steel grating thickness is a critical factor in determining the suitability and performance of grating for various applications. Whether used in industrial flooring, walkways, or stair treads, choosing the right thickness of steel grating ensures safety, durability, and cost-effectiveness.

Trust in the product can often stem from the brand and its compliance with international standards such as ISO, ANSI, or BS. Companies adhering to these standards are more likely to deliver steel gratings with accurate thickness specifications, ensuring safety and reliability. Furthermore, quality certifications provide assurance to the end-users that the product fulfills all necessary performance and safety criteria. One of the most authoritative pieces of advice is to consult with structural engineers or qualified professionals when selecting steel grating thickness. These experts can conduct a thorough assessment of the site conditions, load demands, and environmental factors to stipulate the most appropriate thickness. Moreover, leveraging advanced software and modeling technologies allows for precise calculations that optimize performance while minimizing costs. Trustworthiness in suppliers is another critical element. Reliable manufacturers and distributors typically provide detailed technical information and support, aiding clients in making informed decisions about the appropriate thickness for their specific applications. User testimonials and case studies can also offer valuable insights, highlighting successful installations and long-term performance outcomes. Finally, experience plays a vital role in understanding the nuances of steel grating thickness. Companies with years of practical field experience tend to offer more innovative solutions and customization options. They understand market trends and frequently engage in research and development to improve material compositions and manufacturing processes, ultimately enhancing product performance. In conclusion, determining the right steel grating thickness involves a comprehensive understanding of application requirements, material properties, compliance with standards, and industry expertise. By aligning these factors, individuals and businesses can make informed decisions that ensure safety, efficiency, and longevity of their steel grating installations.

Trust in the product can often stem from the brand and its compliance with international standards such as ISO, ANSI, or BS. Companies adhering to these standards are more likely to deliver steel gratings with accurate thickness specifications, ensuring safety and reliability. Furthermore, quality certifications provide assurance to the end-users that the product fulfills all necessary performance and safety criteria. One of the most authoritative pieces of advice is to consult with structural engineers or qualified professionals when selecting steel grating thickness. These experts can conduct a thorough assessment of the site conditions, load demands, and environmental factors to stipulate the most appropriate thickness. Moreover, leveraging advanced software and modeling technologies allows for precise calculations that optimize performance while minimizing costs. Trustworthiness in suppliers is another critical element. Reliable manufacturers and distributors typically provide detailed technical information and support, aiding clients in making informed decisions about the appropriate thickness for their specific applications. User testimonials and case studies can also offer valuable insights, highlighting successful installations and long-term performance outcomes. Finally, experience plays a vital role in understanding the nuances of steel grating thickness. Companies with years of practical field experience tend to offer more innovative solutions and customization options. They understand market trends and frequently engage in research and development to improve material compositions and manufacturing processes, ultimately enhancing product performance. In conclusion, determining the right steel grating thickness involves a comprehensive understanding of application requirements, material properties, compliance with standards, and industry expertise. By aligning these factors, individuals and businesses can make informed decisions that ensure safety, efficiency, and longevity of their steel grating installations.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

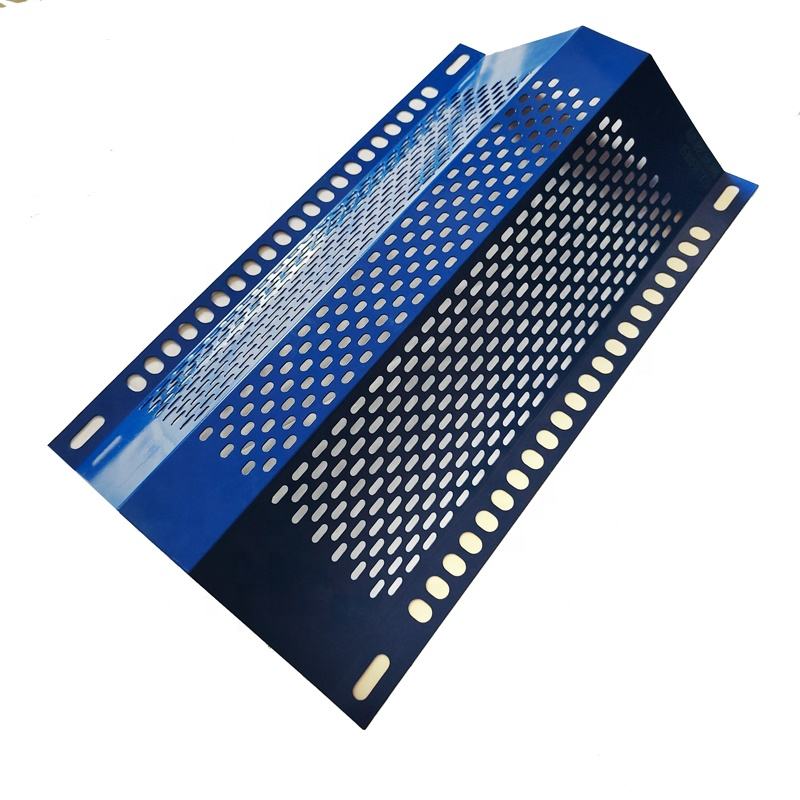

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP