2 月 . 13, 2025 10:32

Back to list

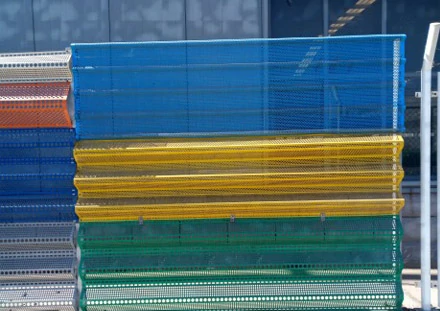

aluminum sheet with holes

Aluminum sheets with holes, often referred to as perforated aluminum sheets, have become a staple in both industrial and architectural applications. Their versatility and efficiency are unparalleled, and their usage spans numerous industries due to the wide range of benefits they offer. As someone with significant expertise in materials and design, I've seen firsthand how these lightweight yet durable sheets transform projects by providing practical solutions without sacrificing aesthetics.

In architectural designs, the aesthetic possibilities are virtually limitless. Designers often employ perforated aluminum sheets to create visually striking facades and interior wall panels. By manipulating light and shadow, these sheets add a dynamic element to buildings during different times of the day. Moreover, they serve an essential role in improving natural ventilation and allowing diffused natural light into spaces, contributing to energy-efficient buildings that align with modern environmental standards. Moreover, these sheets are incredibly eco-friendly. Aluminum is a highly recyclable material, ensuring that the environmental impact of using aluminum sheets with holes is minimal. The recyclability of aluminum not only makes it an attractive choice for environmentally conscious projects but also ensures long-term cost efficiency. The conversion of spent aluminum into new sheets requires considerably less energy compared to raw aluminum production, thus reinforcing sustainability in the lifecycle of projects. Experts recommend considering factors such as hole pattern, sheet thickness, and finish before settling on a type of perforated aluminum sheet for specific applications. Hole patterns — staggered or straight — affect both the appearance and performance characteristics, such as translucence and strength. Sheet thickness determines the load-bearing capacity and durability under various environmental conditions. Lastly, finishes like anodizing or powder-coating can enhance the corrosion resistance and aesthetic attributes, making them suitable for prolonged outdoor use. In summary, aluminum sheets with holes redefine utility with their multifunctional applications across industries. These sheets harmonize strength, adaptability, and aesthetics in ways few other materials can achieve. Their impact on eco-friendly and innovative design is profound, encouraging architects, engineers, and manufacturers to continuously explore new potentials. Embracing the shift towards sustainable practices while maintaining optimum performance standards speaks to the future of material science, positioning perforated aluminum sheets as a cornerstone in modern applications.

In architectural designs, the aesthetic possibilities are virtually limitless. Designers often employ perforated aluminum sheets to create visually striking facades and interior wall panels. By manipulating light and shadow, these sheets add a dynamic element to buildings during different times of the day. Moreover, they serve an essential role in improving natural ventilation and allowing diffused natural light into spaces, contributing to energy-efficient buildings that align with modern environmental standards. Moreover, these sheets are incredibly eco-friendly. Aluminum is a highly recyclable material, ensuring that the environmental impact of using aluminum sheets with holes is minimal. The recyclability of aluminum not only makes it an attractive choice for environmentally conscious projects but also ensures long-term cost efficiency. The conversion of spent aluminum into new sheets requires considerably less energy compared to raw aluminum production, thus reinforcing sustainability in the lifecycle of projects. Experts recommend considering factors such as hole pattern, sheet thickness, and finish before settling on a type of perforated aluminum sheet for specific applications. Hole patterns — staggered or straight — affect both the appearance and performance characteristics, such as translucence and strength. Sheet thickness determines the load-bearing capacity and durability under various environmental conditions. Lastly, finishes like anodizing or powder-coating can enhance the corrosion resistance and aesthetic attributes, making them suitable for prolonged outdoor use. In summary, aluminum sheets with holes redefine utility with their multifunctional applications across industries. These sheets harmonize strength, adaptability, and aesthetics in ways few other materials can achieve. Their impact on eco-friendly and innovative design is profound, encouraging architects, engineers, and manufacturers to continuously explore new potentials. Embracing the shift towards sustainable practices while maintaining optimum performance standards speaks to the future of material science, positioning perforated aluminum sheets as a cornerstone in modern applications.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP