2 月 . 13, 2025 10:13

Back to list

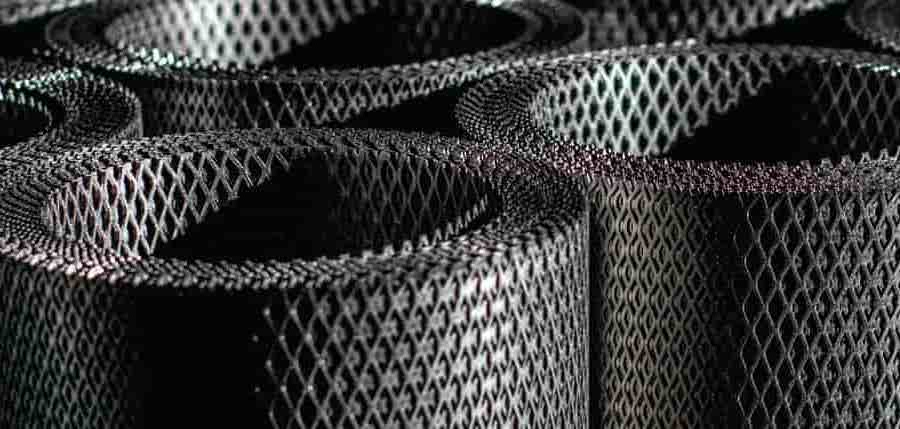

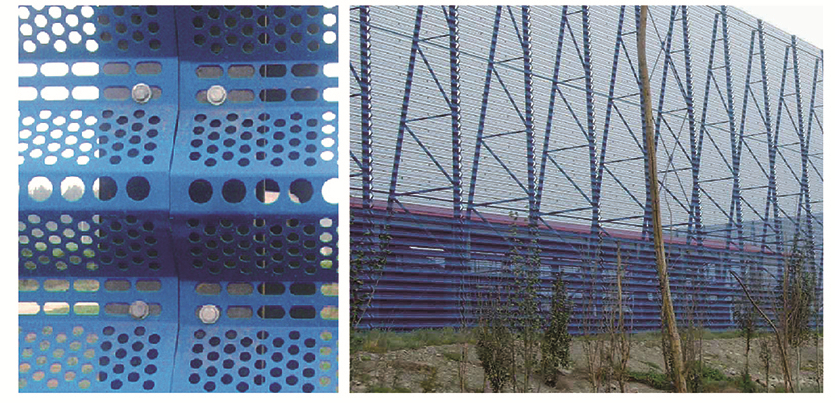

anti slip perforated metal sheet

In the realm of industrial and architectural materials, anti-slip perforated metal sheets stand out for their functionality and versatility. These materials are not only crucial for enhancing safety across various platforms and surfaces but also add a layer of aesthetic appeal when incorporated into design-forward projects.

Despite their complex manufacturing process, anti-slip perforated metal sheets remain a cost-effective solution for projects demanding both safety and longevity. Their installation is relatively straightforward, which reduces labor costs and overall project duration. Furthermore, their low maintenance nature—owing to their resistance to environmental wear and tear—provides additional cost savings over time, cementing their value proposition. In terms of authoritativeness and trustworthiness, numerous case studies highlight the sheet's effectiveness in various settings, from reducing slip-related accidents in factories to enhancing the aesthetic of modern architectural designs. Industry testimonials often underscore the reliability of these sheets, noting their role in not only preventing workplace injuries but also in preserving the integrity of design projects where aesthetics cannot be compromised. Contractors and designers choosing anti-slip perforated metal sheets are making an informed decision backed by industry standards and positive user experiences. These sheets are often certified by safety organizations, which adds another layer of credibility to their use in safety-critical applications. In summation, anti-slip perforated metal sheets offer an optimal combination of safety, durability, and design versatility. Whether used in industrial settings or incorporated into architectural projects, these sheets deliver measurable benefits that extend beyond their primary function. Their contribution to safety, when paired with aesthetic value, makes them an indispensable material in today's design landscape. As we continue to push the boundaries of what design and functionality can achieve together, these metal sheets remain at the forefront, exemplifying innovation and practical ingenuity in material science.

Despite their complex manufacturing process, anti-slip perforated metal sheets remain a cost-effective solution for projects demanding both safety and longevity. Their installation is relatively straightforward, which reduces labor costs and overall project duration. Furthermore, their low maintenance nature—owing to their resistance to environmental wear and tear—provides additional cost savings over time, cementing their value proposition. In terms of authoritativeness and trustworthiness, numerous case studies highlight the sheet's effectiveness in various settings, from reducing slip-related accidents in factories to enhancing the aesthetic of modern architectural designs. Industry testimonials often underscore the reliability of these sheets, noting their role in not only preventing workplace injuries but also in preserving the integrity of design projects where aesthetics cannot be compromised. Contractors and designers choosing anti-slip perforated metal sheets are making an informed decision backed by industry standards and positive user experiences. These sheets are often certified by safety organizations, which adds another layer of credibility to their use in safety-critical applications. In summation, anti-slip perforated metal sheets offer an optimal combination of safety, durability, and design versatility. Whether used in industrial settings or incorporated into architectural projects, these sheets deliver measurable benefits that extend beyond their primary function. Their contribution to safety, when paired with aesthetic value, makes them an indispensable material in today's design landscape. As we continue to push the boundaries of what design and functionality can achieve together, these metal sheets remain at the forefront, exemplifying innovation and practical ingenuity in material science.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP