2 月 . 14, 2025 10:09

Back to list

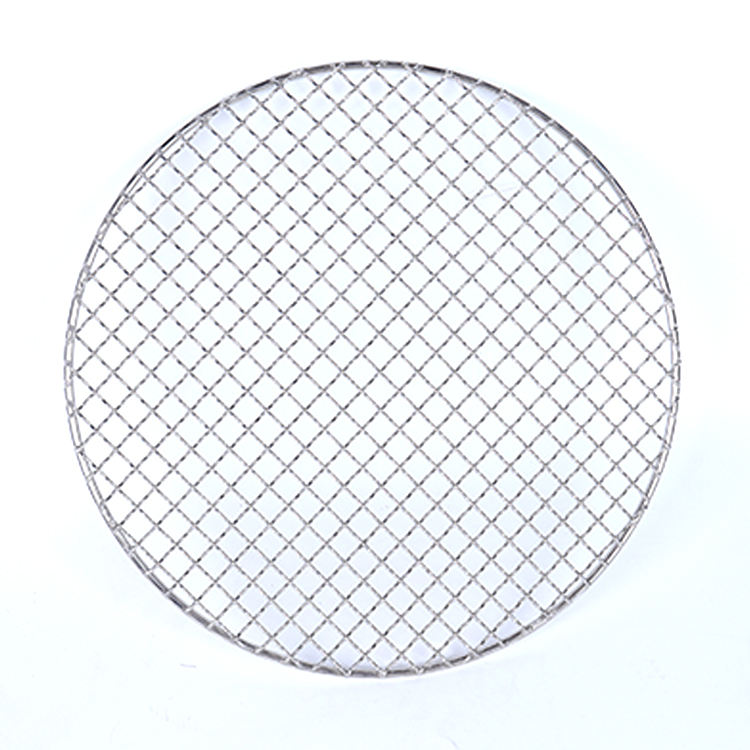

1 mm perforated stainless steel sheet

When it comes to selecting materials for construction, art installations, or architectural projects, the 1 mm perforated stainless steel sheet stands out as a versatile candidate. Its blend of durability, aesthetic appeal, and practicality makes it an unparalleled choice for a variety of applications. This article delves into the intrinsic qualities of perforated stainless steel sheets, their diverse applications, and why they are a top pick among professionals who seek excellence.

The environmental benefits further solidify the standing of 1 mm perforated stainless steel sheets. Stainless steel is highly recyclable, reducing wastage and promoting sustainable development practices. The production of these materials involves significant energy efficiency, and their longevity means they require less frequent replacement than other materials. This aspect is particularly appealing in today’s eco-conscious market, aligning with the global shift towards sustainable construction practices. The reliability of stainless steel in harsh environmental conditions cannot be overemphasized. Its corrosion resistance ensures that the material remains in pristine condition even when exposed to moisture or saline environments, such as coastal installations. This reliability makes it a trusted choice for outdoor applications where other materials might deteriorate more rapidly. For professionals looking for authoritative guidance on material selection, the endorsement of 1 mm perforated stainless steel sheets by experts speaks volumes. Engineers and architects, backed by years of experience, frequently recommend it not only for its functional advantages but also for its role in enhancing project timelines and reducing costs associated with maintenance and material replacement. In conclusion, the 1 mm perforated stainless steel sheet represents a harmonious blend of strength, beauty, and functionality. Its adaptability across various industries underscores its relevance and the growing trust professionals place in its capabilities. Whether for its sustainability credentials, aesthetic potential, or unrivaled durability, this material continues to be a premier choice among discerning professionals who demand the best from their materials.

The environmental benefits further solidify the standing of 1 mm perforated stainless steel sheets. Stainless steel is highly recyclable, reducing wastage and promoting sustainable development practices. The production of these materials involves significant energy efficiency, and their longevity means they require less frequent replacement than other materials. This aspect is particularly appealing in today’s eco-conscious market, aligning with the global shift towards sustainable construction practices. The reliability of stainless steel in harsh environmental conditions cannot be overemphasized. Its corrosion resistance ensures that the material remains in pristine condition even when exposed to moisture or saline environments, such as coastal installations. This reliability makes it a trusted choice for outdoor applications where other materials might deteriorate more rapidly. For professionals looking for authoritative guidance on material selection, the endorsement of 1 mm perforated stainless steel sheets by experts speaks volumes. Engineers and architects, backed by years of experience, frequently recommend it not only for its functional advantages but also for its role in enhancing project timelines and reducing costs associated with maintenance and material replacement. In conclusion, the 1 mm perforated stainless steel sheet represents a harmonious blend of strength, beauty, and functionality. Its adaptability across various industries underscores its relevance and the growing trust professionals place in its capabilities. Whether for its sustainability credentials, aesthetic potential, or unrivaled durability, this material continues to be a premier choice among discerning professionals who demand the best from their materials.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP