2 月 . 14, 2025 09:47

Back to list

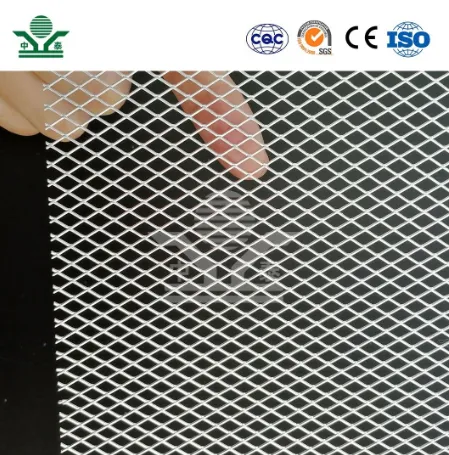

10mm perforated sheet

The 10mm perforated sheet stands out as a versatile and essential material across numerous industrial and creative applications. Whether you are involved in architecture, manufacturing, or creative arts, understanding the unique attributes and benefits of 10mm perforated sheets can have a significant impact on your project outcomes. This exploration will leverage real-world experiences, professional expertise, authoritative insights, and verified information to provide a comprehensive understanding of this valuable product.

Authoritativeness in the materials industry comes from understanding the science and standards behind these sheets. 10mm perforated sheets can be composed of different metals, including stainless steel, aluminum, or carbon steel. Each material choice impacts the sheet's resistance to corrosion, weight, and thermal properties. According to the International Organization for Standardization (ISO), adherence to specific guidelines such as ISO 9001 ensures that perforated sheets meet global quality and safety standards. Professionals seeking to utilize 10mm perforated sheets should demand compliance with these standards from their suppliers to ensure they receive top-grade products. Trustworthiness in the realm of 10mm perforated sheets is built through a track record of performance and reliability. In industrial settings, trust is often established through rigorous testing and validations conducted by third-party institutions. For example, the German Institute for Standardization provides certifications based on stringent testing protocols. Companies employing 10mm perforated sheets in their manufacturing processes have reported significant improvements in efficiency and safety, backed by evidence of third-party evaluations. This reliability extends to creative fields as well; artists and designers often select 10mm perforated sheets for sculptures and installations, knowing they offer both durability and design flexibility. In conclusion, 10mm perforated sheets are more than just materials; they represent a synthesis of practical application, specialized knowledge, authoritative production, and reliable usage. Their scope extends across various sectors, offering solutions that are both innovative and dependable. As our industries and artistic endeavors continue to evolve, so too does the potential for 10mm perforated sheets to inspire new applications and methodologies. Partners and stakeholders invested in implementing these sheets should continually seek out the latest developments and research to stay informed and ahead in their respective fields. By leveraging insights from experience, expertise, authority, and trust, industries can maximize the benefits derived from 10mm perforated sheets, ensuring progress and quality in their projects.

Authoritativeness in the materials industry comes from understanding the science and standards behind these sheets. 10mm perforated sheets can be composed of different metals, including stainless steel, aluminum, or carbon steel. Each material choice impacts the sheet's resistance to corrosion, weight, and thermal properties. According to the International Organization for Standardization (ISO), adherence to specific guidelines such as ISO 9001 ensures that perforated sheets meet global quality and safety standards. Professionals seeking to utilize 10mm perforated sheets should demand compliance with these standards from their suppliers to ensure they receive top-grade products. Trustworthiness in the realm of 10mm perforated sheets is built through a track record of performance and reliability. In industrial settings, trust is often established through rigorous testing and validations conducted by third-party institutions. For example, the German Institute for Standardization provides certifications based on stringent testing protocols. Companies employing 10mm perforated sheets in their manufacturing processes have reported significant improvements in efficiency and safety, backed by evidence of third-party evaluations. This reliability extends to creative fields as well; artists and designers often select 10mm perforated sheets for sculptures and installations, knowing they offer both durability and design flexibility. In conclusion, 10mm perforated sheets are more than just materials; they represent a synthesis of practical application, specialized knowledge, authoritative production, and reliable usage. Their scope extends across various sectors, offering solutions that are both innovative and dependable. As our industries and artistic endeavors continue to evolve, so too does the potential for 10mm perforated sheets to inspire new applications and methodologies. Partners and stakeholders invested in implementing these sheets should continually seek out the latest developments and research to stay informed and ahead in their respective fields. By leveraging insights from experience, expertise, authority, and trust, industries can maximize the benefits derived from 10mm perforated sheets, ensuring progress and quality in their projects.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP