2 月 . 14, 2025 09:27

Back to list

16 gauge perforated sheet metal

Understanding the true value and utility of 16 gauge perforated sheet metal involves delving into its remarkable versatility and practical applications. This unique material stands out as an engineering marvel, and its benefits extend across various industries, making it indispensable in modern design and construction.

For those in the automotive industry, the intersection of strength and flexibility afforded by 16 gauge perforated sheet metal facilitates inventive design and functionality. Used in vehicle grilles, soundproofing, and heat dissipation components, the sheet’s substantial yet manageable thickness accommodates the intricate shapes required in auto body design and functional accessories, ensuring both safety and style. Moreover, its contribution to acoustic management cannot be overstated. Sound engineers exploit the material's properties to create barriers and panels designed to absorb or redirect sound waves, improving the acoustic quality of theaters, studios, and public spaces. The specific gauge is effective in reducing noise pollution, demonstrating its importance beyond mere structural applications. Professionals employing 16 gauge perforated sheet metal must consider the material composition and finish, as these factors influence corrosion resistance and visual appeal. Various coatings and treatments, such as galvanization, anodization, or powder-coating, enhance the metal's longevity and adaptability in different environments. Educational initiatives and workshops for those entering fields that use this metal can dramatically improve the understanding and innovation involving its use. Engineers, architects, and designers should seek continuous education to stay abreast of new developments and techniques associated with this material. As technology and methods advance, maintaining an up-to-date knowledge base ensures the effective and innovative application of 16 gauge perforated sheet metal. In conclusion, 16 gauge perforated sheet metal is not merely a component of construction; it represents a confluence of strength, sophistication, and sustainability. Its application promises to evolve continuously, meeting new challenges and requirements as they arise in various industries. For businesses and professionals looking to refine their craft and products, leveraging the qualities of this remarkable material can lead to tinnovative solutions and significant improvements in both performance and aesthetics.

For those in the automotive industry, the intersection of strength and flexibility afforded by 16 gauge perforated sheet metal facilitates inventive design and functionality. Used in vehicle grilles, soundproofing, and heat dissipation components, the sheet’s substantial yet manageable thickness accommodates the intricate shapes required in auto body design and functional accessories, ensuring both safety and style. Moreover, its contribution to acoustic management cannot be overstated. Sound engineers exploit the material's properties to create barriers and panels designed to absorb or redirect sound waves, improving the acoustic quality of theaters, studios, and public spaces. The specific gauge is effective in reducing noise pollution, demonstrating its importance beyond mere structural applications. Professionals employing 16 gauge perforated sheet metal must consider the material composition and finish, as these factors influence corrosion resistance and visual appeal. Various coatings and treatments, such as galvanization, anodization, or powder-coating, enhance the metal's longevity and adaptability in different environments. Educational initiatives and workshops for those entering fields that use this metal can dramatically improve the understanding and innovation involving its use. Engineers, architects, and designers should seek continuous education to stay abreast of new developments and techniques associated with this material. As technology and methods advance, maintaining an up-to-date knowledge base ensures the effective and innovative application of 16 gauge perforated sheet metal. In conclusion, 16 gauge perforated sheet metal is not merely a component of construction; it represents a confluence of strength, sophistication, and sustainability. Its application promises to evolve continuously, meeting new challenges and requirements as they arise in various industries. For businesses and professionals looking to refine their craft and products, leveraging the qualities of this remarkable material can lead to tinnovative solutions and significant improvements in both performance and aesthetics.

Latest news

-

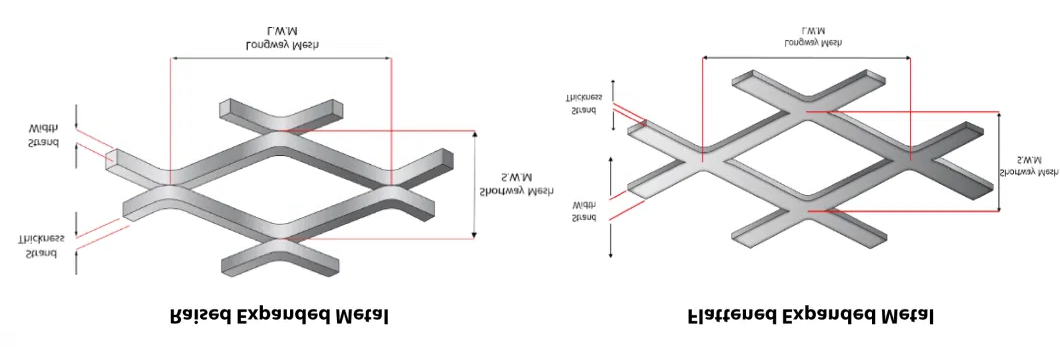

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP