Understanding Wire Grating A Multifaceted Approach to Structural and Optical Applications

Wire grating, a term often used in engineering and materials science, refers to a structure formed by a series of parallel wires or metallic filaments spaced at regular intervals. This configuration can be utilized for a variety of applications, ranging from structural support to advanced optical systems. The interplay of design, materials, and applications makes wire grating an intriguing subject worthy of exploration.

The Basics of Wire Grating

At its core, wire grating consists of an array of wires that can be arranged in a variety of geometrical patterns. The wires are typically made from durable materials such as stainless steel, aluminum, or even specialized alloys, granting them excellent strength-to-weight ratios. One of the primary functions of wire grating is to provide a platform for load-bearing in a variety of environments, including industrial, commercial, and residential settings.

In terms of structural applications, wire gratings are commonly used in flooring systems, catwalks, or protective enclosures. They allow for ventilation and light to pass through while maintaining a high degree of strength and stability. The open design of wire grate systems facilitates drainage in wet conditions, making them particularly useful in industrial applications like factories and wastewater treatment plants.

Optical Properties of Wire Grating

Beyond their structural capabilities, wire gratings display fascinating optical properties due to their periodic structure. This makes them useful in areas such as photonics and optics. When light encounters a wire grating, it can diffract in particular directions depending on the spacing of the wires and the wavelength of the incoming light. This property can be harnessed for applications such as diffraction gratings in spectrometers, which are essential tools in analytical chemistry and physics.

wire grating

The ability to manipulate light using wire grating techniques has led to advances in sensor technology and telecommunications. For example, wire gratings can be employed in sensors that detect changes in environmental conditions or chemical compositions based on variations in light diffraction patterns. This has immense implications for industries like environmental monitoring and medical diagnostics.

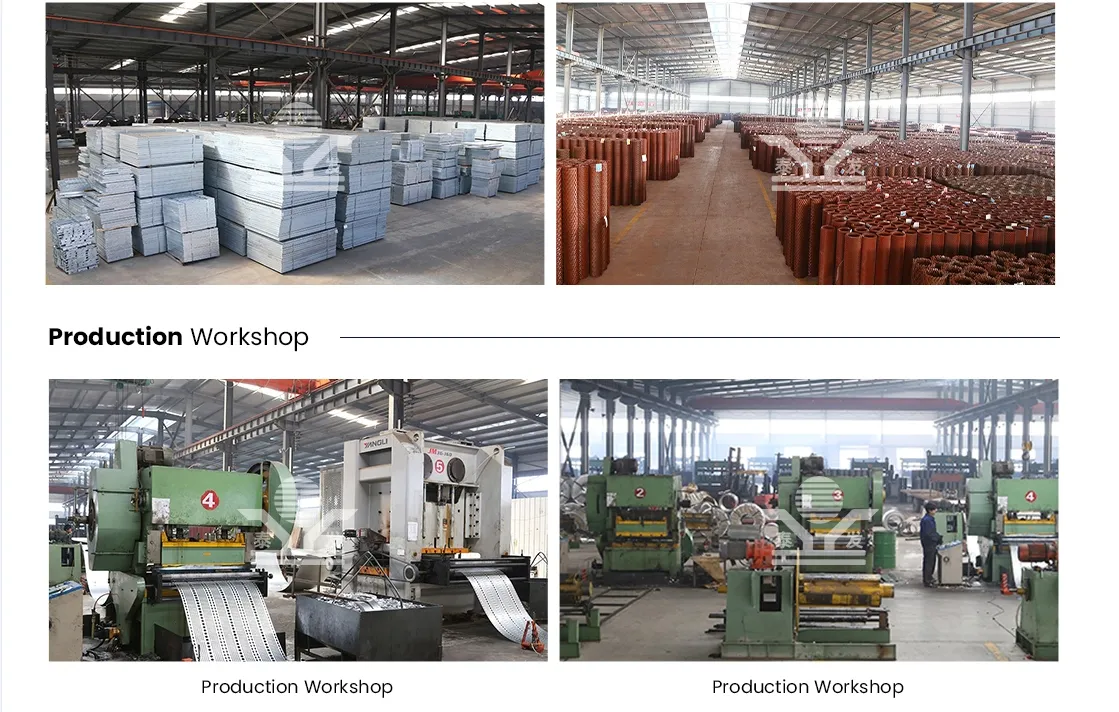

Advances in Materials and Manufacturing

Recent innovations in manufacturing technologies have allowed for the production of wire gratings with more precise dimensions and configurations. Techniques such as laser cutting and 3D printing have opened new avenues for creating intricate wire grating designs. Additionally, the development of advanced materials, such as composites or smart materials, allows for harder, lighter, and more resilient wire gratings.

The integration of modern materials science with traditional wire grating techniques is leading to a new era of applications. For instance, responsive wire gratings that can change their structural or optical properties based on external stimuli are being researched, potentially revolutionizing fields such as adaptive optics and structural health monitoring.

Conclusion

Wire grating represents a versatile and dynamic structure with diverse applications in both structural engineering and optics. As ongoing research leads to advancements in manufacturing and materials, the potential applications of wire gratings will continue to expand. From robust flooring solutions to intricate optical devices, wire gratings are poised to play an essential role in shaping the technologies of the future. As industries increasingly recognize their value, the importance of wire grating in our everyday lives is set to grow, illuminating the pathway forward in engineering and applied sciences.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.