1 月 . 21, 2025 04:36

Back to list

Stainless Wire Mesh China Manufacturers Stainless Steel Woven Wire Cloth 0.58mm Diameter Stainless Steel Mesh

Wire grating offers an unparalleled blend of functionality, durability, and safety, making it an essential component in a multitude of industrial and commercial applications. With its unique grid-like structure, wire grating provides superior load-bearing capacity and slip-resistant surfaces, ensuring both practicality and safety in various settings. This article delves into the expert knowledge surrounding wire grating, offering insights into its benefits, applications, and considerations for optimal use.

When selecting wire grating, it’s crucial to consider load requirements and spacing. The choice of grating type—such as welded, press-locked, or riveted—depends on specific project needs and the expected load. Welded grating, known for its strength and simplicity, is often used in heavy-duty applications. Conversely, press-locked grating is preferred for architectural aesthetics, offering a smoother surface without compromising on strength. Riveted grating, a more traditional option, provides maximum strength and durability under stress, making it suitable for extreme conditions. Installation of wire grating requires expertise to ensure stability and safety. Careful measurement and custom fabrication may be necessary to fit unusual spaces or achieve unique design specifications. Experienced professionals can provide guidance on best practices for installation, thus ensuring compliance with safety regulations and extending the structure’s utility and durability. In terms of maintenance, wire grating is relatively low-maintenance, especially when made from corrosion-resistant materials. Regular inspections to check for any damage or wear, particularly in high-traffic areas, help in maintaining the structural integrity and safety of the installations. Keeping the grating clean with periodic rinsing or sweeping can also preserve its appearance and performance over time. In conclusion, wire grating stands out as a vital material for a wide array of applications, from industrial floors to modern architectural statements. Its strength, versatility, and aesthetic appeal make it a preferred choice among professionals seeking reliable and functional solutions. When chosen and installed correctly, wire grating delivers long-lasting performance and safety, proving to be an invaluable asset in both industrial and commercial domains. As advancements in materials and technology continue, wire grating remains at the forefront, adapting to meet evolving demands and cementing its place as a staple in infrastructure development.

When selecting wire grating, it’s crucial to consider load requirements and spacing. The choice of grating type—such as welded, press-locked, or riveted—depends on specific project needs and the expected load. Welded grating, known for its strength and simplicity, is often used in heavy-duty applications. Conversely, press-locked grating is preferred for architectural aesthetics, offering a smoother surface without compromising on strength. Riveted grating, a more traditional option, provides maximum strength and durability under stress, making it suitable for extreme conditions. Installation of wire grating requires expertise to ensure stability and safety. Careful measurement and custom fabrication may be necessary to fit unusual spaces or achieve unique design specifications. Experienced professionals can provide guidance on best practices for installation, thus ensuring compliance with safety regulations and extending the structure’s utility and durability. In terms of maintenance, wire grating is relatively low-maintenance, especially when made from corrosion-resistant materials. Regular inspections to check for any damage or wear, particularly in high-traffic areas, help in maintaining the structural integrity and safety of the installations. Keeping the grating clean with periodic rinsing or sweeping can also preserve its appearance and performance over time. In conclusion, wire grating stands out as a vital material for a wide array of applications, from industrial floors to modern architectural statements. Its strength, versatility, and aesthetic appeal make it a preferred choice among professionals seeking reliable and functional solutions. When chosen and installed correctly, wire grating delivers long-lasting performance and safety, proving to be an invaluable asset in both industrial and commercial domains. As advancements in materials and technology continue, wire grating remains at the forefront, adapting to meet evolving demands and cementing its place as a staple in infrastructure development.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

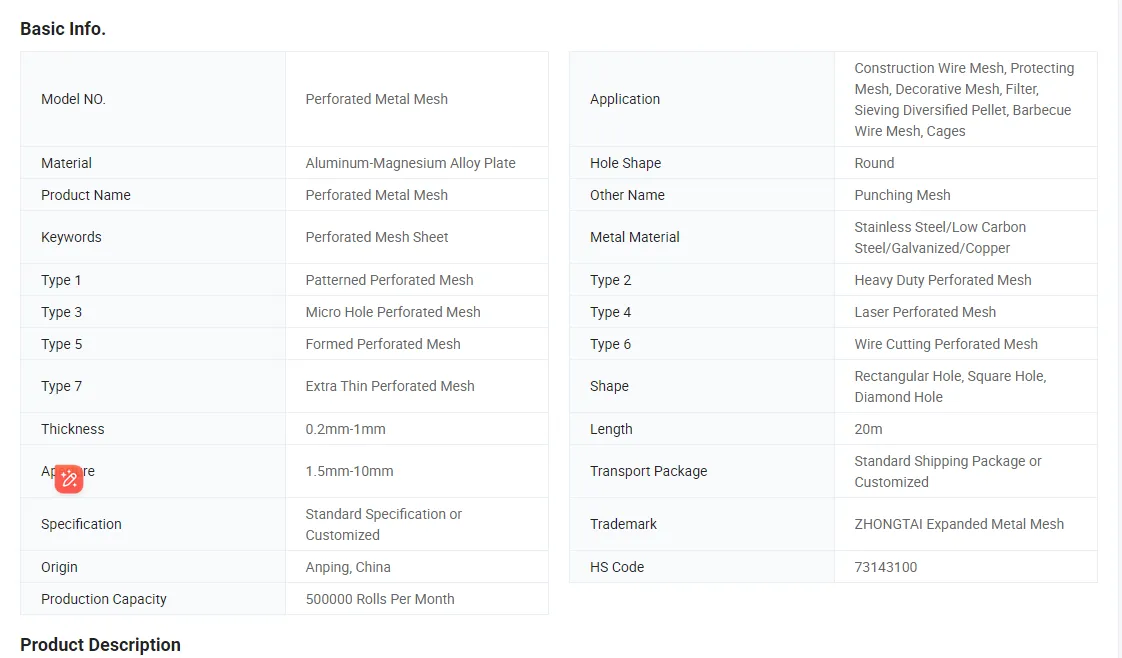

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP