1 月 . 22, 2025 01:39

Back to list

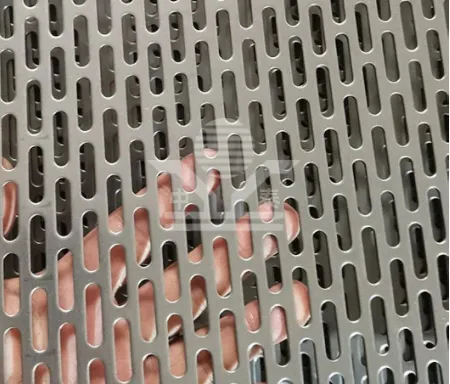

welded bar grating

Welded bar grating is an essential product in industrial flooring, offering both strength and versatility. Known for its robust structure, it is widely appreciated by engineers, architects, and construction managers for its ability to withstand substantial loads while maintaining a lightweight profile.

One of the defining features of welded bar grating is its adaptability. It can be customized with various bar thicknesses, depths, and spacing to meet specific project requirements or to adhere to industry regulations and safety standards. This adaptability extends to its surface finish as well, with options like galvanized for enhanced rust resistance, or painted finishes for aesthetic purposes. Selecting the right welded bar grating involves understanding the specific needs of a project, including the load requirements, environmental conditions, and regulatory compliance guidelines. Consulting with grating specialists can provide invaluable insights, ensuring the chosen product not only meets but exceeds performance expectations. This expert advice can be instrumental in ensuring safety, efficiency, and reliability in areas subject to extensive usage or environmental stresses. Trust in welded bar grating is not just grounded in product specifications and material properties but is also tied to the reputations of manufacturers and suppliers. Established providers often offer warranties and are willing to assist with installation advice and after-sales support, reinforcing their credibility and commitment to quality assurance. Verifying the supplier’s certifications and their adherence to industry standards can further bolster confidence in the product’s performance. In summary, welded bar grating stands as a quintessential component in the arsenal of modern construction and industrial projects. Its impressive combination of strength, adaptability, and durability makes it a preferred choice for professionals seeking reliable, cost-effective solutions for complex challenges. By embracing this remarkable product, industries can leverage its benefits to enhance safety, operational efficiency, and longevity of infrastructure.

One of the defining features of welded bar grating is its adaptability. It can be customized with various bar thicknesses, depths, and spacing to meet specific project requirements or to adhere to industry regulations and safety standards. This adaptability extends to its surface finish as well, with options like galvanized for enhanced rust resistance, or painted finishes for aesthetic purposes. Selecting the right welded bar grating involves understanding the specific needs of a project, including the load requirements, environmental conditions, and regulatory compliance guidelines. Consulting with grating specialists can provide invaluable insights, ensuring the chosen product not only meets but exceeds performance expectations. This expert advice can be instrumental in ensuring safety, efficiency, and reliability in areas subject to extensive usage or environmental stresses. Trust in welded bar grating is not just grounded in product specifications and material properties but is also tied to the reputations of manufacturers and suppliers. Established providers often offer warranties and are willing to assist with installation advice and after-sales support, reinforcing their credibility and commitment to quality assurance. Verifying the supplier’s certifications and their adherence to industry standards can further bolster confidence in the product’s performance. In summary, welded bar grating stands as a quintessential component in the arsenal of modern construction and industrial projects. Its impressive combination of strength, adaptability, and durability makes it a preferred choice for professionals seeking reliable, cost-effective solutions for complex challenges. By embracing this remarkable product, industries can leverage its benefits to enhance safety, operational efficiency, and longevity of infrastructure.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP