The Versatility of Perforated White Metal Sheets An Overview

Perforated white metal sheets are an innovative design solution that combines aesthetic appeal with functional practicality. These sheets are made from various metals such as aluminum, steel, or stainless steel, and are characterized by a series of holes punched through the material. The finish of these sheets, often powder-coated in white, enhances their visual appeal and makes them a favorite choice in diverse applications ranging from architecture to industrial settings.

One of the primary benefits of perforated white metal sheets is their lightweight nature while maintaining durability and strength. These sheets provide an excellent balance between functionality and design, making them suitable for various construction and design applications. The perforations allow for light and air to pass through while maintaining a degree of privacy, making them an ideal choice for decorative screens, room dividers, and fence panels in gardens and commercial spaces.

In architectural applications, perforated white metal sheets are increasingly used for facade elements. The holes can be intricately designed to create unique patterns that not only enhance the aesthetics of a building but also control the amount of natural light entering a space. This feature is particularly beneficial in energy-efficient designs, where the perforations contribute to natural ventilation and reduce the need for artificial lighting.

Moreover, these sheets are frequently employed in interior design as wall cladding and ceiling tiles. The use of perforated metal can add a contemporary touch to any interior space, ranging from offices to restaurants. The white finish allows for seamless integration into various design schemes, providing a clean and modern look. Additionally, the acoustic properties of these sheets can help in reducing noise levels in busy environments, making them a practical choice for public spaces.

perforated white metal sheet

Besides architectural uses, perforated white metal sheets find a significant role in industrial applications. They are commonly used as guards and screens in machinery, providing safety without compromising visibility. In manufacturing processes, these sheets can act as filters or separators, allowing for the efficient movement of air, liquids, or materials while preventing the passage of larger objects. Their versatility in different industries is a testament to their functional design.

The maintenance of perforated white metal sheets is another advantage that contributes to their popularity. The powder-coated finish not only enhances their appearance but also protects against corrosion and wear, ensuring a long-lasting product. Regular cleaning and maintenance can significantly prolong the lifespan of these sheets, making them a cost-effective choice for businesses and homeowners alike.

Sustainability is a growing concern in today’s world, and perforated white metal sheets can contribute positively to this movement. Many manufacturers utilize recycled materials in their production, and the durability of these sheets means they can last for years with minimal environmental impact. Furthermore, their ability to contribute to energy efficiency in buildings can reduce overall energy consumption, aligning with global efforts to create more sustainable living and working environments.

In conclusion, perforated white metal sheets represent an intersection of style, functionality, and sustainability. Whether used in architectural designs, interior decor, or industrial applications, these versatile materials offer a wealth of benefits that cater to modern needs. Their unique characteristics not only enhance visual appeal but also provide practical solutions for everyday challenges, making them an invaluable resource in various fields. As design preferences continue to evolve, the significance of perforated white metal sheets in both aesthetic and functional capacities is sure to grow.

-

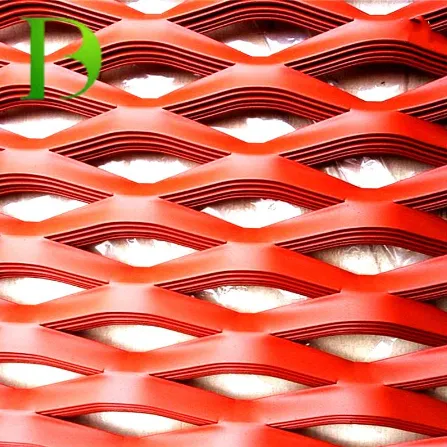

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.