Types of Welded Wire Mesh and Their Applications

Welded wire mesh is a versatile material widely used in various construction, manufacturing, and agricultural applications. It comprises a grid of steel wires that are welded together at intersections, providing a robust and durable structure. This article explores the different types of welded wire mesh and their specific uses, helping you understand which type may be best suited for your needs.

1. Standard Welded Wire Mesh

Standard welded wire mesh is the most common type, consisting of wires arranged in a grid pattern, generally with equal spacing. The wires can vary in thickness and spacing, depending on the intended use. This type of mesh is primarily used in construction for reinforcing concrete slabs, walls, and foundations. It enhances the tensile strength of concrete, making structures more resilient to cracking and deformation.

2. Welded Wire Fencing

Welded wire fencing is another popular application of welded wire mesh. It is typically made from heavier gauge wire to provide increased strength and security. Commonly used in agricultural settings, this type of fencing is effective for keeping livestock secure and contained. It is also employed in residential and commercial properties to enhance security, serve as barrier fencing, and delineate property lines. The durability of welded wire fencing ensures long-lasting performance, even in harsh weather conditions.

Hexagonal welded wire mesh, also known as chicken wire, features hexagonal openings and is primarily used in agriculture for poultry enclosures and garden fencing. The unique shape of the openings provides excellent ventilation while preventing birds and small animals from escaping. Additionally, it can be used to reinforce soil, prevent erosion, and create protective barriers for plants. Its lightweight yet strong design makes it an ideal choice for various gardening and agricultural applications.

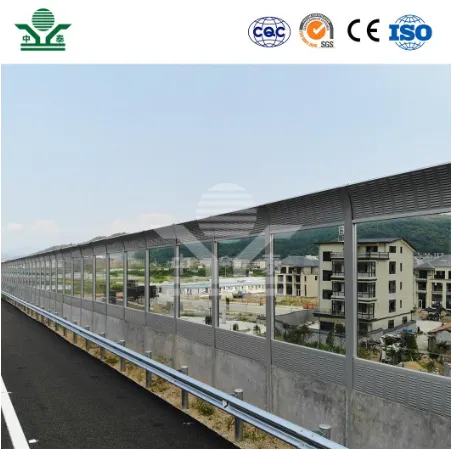

types of welded wire mesh

4. Plastic-Coated Welded Wire Mesh

Plastic-coated welded wire mesh is a corrosion-resistant variant of standard welded wire mesh. The wire is coated with high-quality plastic, providing an additional layer of protection against rust and weathering. This type is commonly used in outdoor applications, such as fencing, gardening, and landscaping, where exposure to moisture and environmental elements is a concern. The plastic coating not only extends the lifespan of the mesh but also provides aesthetic benefits, as it is available in various colors.

5. Galvanized Welded Wire Mesh

Galvanized welded wire mesh is coated with a layer of zinc to enhance its resistance to corrosion and rust. This type of mesh is ideal for use in environments where moisture exposure is common, such as in marine and agricultural applications. Galvanized mesh is commonly used for animal enclosures, garden fencing, and as supports for climbing plants, thanks to its durability and longevity.

6. Reinforcement Mesh

Reinforcement mesh, often made from high-strength steel, is designed for use in concrete reinforcement. It typically features larger openings and thicker wires compared to standard welded wire mesh. This type of mesh is primarily used in heavy construction projects, including roadways, bridges, and large commercial structures. It helps distribute loads and provide stability, ensuring that concrete structures can withstand stress and strain over time.

Conclusion

Welded wire mesh comes in various types, each designed to meet specific requirements ranging from construction and fencing to agricultural applications. Understanding the differences between these types can help you choose the right mesh for your project. Whether you need standard mesh for reinforcement, fencing solutions for security, or specialized products like hexagonal or plastic-coated mesh, welded wire mesh offers a reliable and effective solution across numerous industries. By selecting the appropriate type, you can ensure structural integrity, security, and longevity in your applications, making welded wire mesh an invaluable asset in modern construction and design.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.