1 月 . 20, 2025 15:55

Back to list

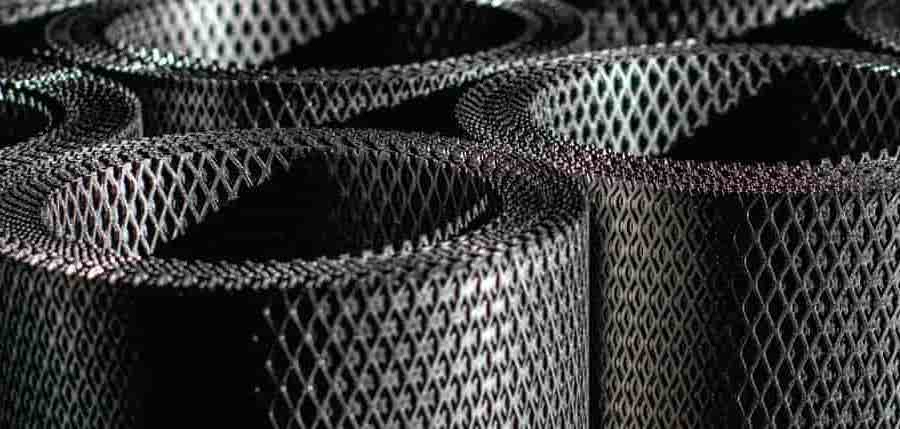

Hot-dip galvanized steel grating

Steel grating has emerged as an essential component in various industrial and architectural applications, offering a combination of strength, durability, and versatility. Understanding the types of steel grating available in the market is crucial for making informed decisions that align with specific project requirements. This exploration into the world of steel grating delves into various types, highlighting their unique characteristics, applications, and benefits.

Beyond construction methods, steel grating is versatile in the materials used. Common materials include carbon steel, which provides a cost-effective solution with excellent load-bearing properties. Likewise, stainless steel grating is prized for its resistance to corrosion, making it ideal for environments prone to moisture or chemical exposure. Additionally, aluminum grating offers a lightweight and corrosion-resistant option suitable for applications where reducing the overall weight is a concern without compromising strength. The choice of grating also extends to the type of finishes, which significantly enhances performance and longevity. Galvanized coatings, for instance, are widely used to protect against rust and extend the life of the grating, particularly in outdoor or industrial environments. An understanding of these finishes is vital for ensuring that the chosen grating will withstand the operational conditions it will face over its lifespan. In every application, from industrial flooring to platform panels and architectural facades, selecting the appropriate type of steel grating is a decision that impacts both safety and performance. Expertise in steel grating selection comes from a comprehensive understanding of the specific conditions and requirements of each project. Consulting with industry experts and leveraging supplier knowledge ensures that the grating will not only meet immediate functional needs but also provide a sustainable solution over time. Furthermore, attention to compliance with industry standards and safety regulations is essential. Trustworthy suppliers and manufacturers will provide certificates and documentation verifying that their products adhere to recognized standards, providing an additional layer of assurance. By considering all these factors, professionals are equipped to make informed decisions that enhance project outcomes. The authority and reliability of the products selected contribute significantly to their effectiveness across various applications, ensuring peace of mind and confidence in their durability and safety.

Beyond construction methods, steel grating is versatile in the materials used. Common materials include carbon steel, which provides a cost-effective solution with excellent load-bearing properties. Likewise, stainless steel grating is prized for its resistance to corrosion, making it ideal for environments prone to moisture or chemical exposure. Additionally, aluminum grating offers a lightweight and corrosion-resistant option suitable for applications where reducing the overall weight is a concern without compromising strength. The choice of grating also extends to the type of finishes, which significantly enhances performance and longevity. Galvanized coatings, for instance, are widely used to protect against rust and extend the life of the grating, particularly in outdoor or industrial environments. An understanding of these finishes is vital for ensuring that the chosen grating will withstand the operational conditions it will face over its lifespan. In every application, from industrial flooring to platform panels and architectural facades, selecting the appropriate type of steel grating is a decision that impacts both safety and performance. Expertise in steel grating selection comes from a comprehensive understanding of the specific conditions and requirements of each project. Consulting with industry experts and leveraging supplier knowledge ensures that the grating will not only meet immediate functional needs but also provide a sustainable solution over time. Furthermore, attention to compliance with industry standards and safety regulations is essential. Trustworthy suppliers and manufacturers will provide certificates and documentation verifying that their products adhere to recognized standards, providing an additional layer of assurance. By considering all these factors, professionals are equipped to make informed decisions that enhance project outcomes. The authority and reliability of the products selected contribute significantly to their effectiveness across various applications, ensuring peace of mind and confidence in their durability and safety.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP