2 月 . 07, 2025 02:00

Back to list

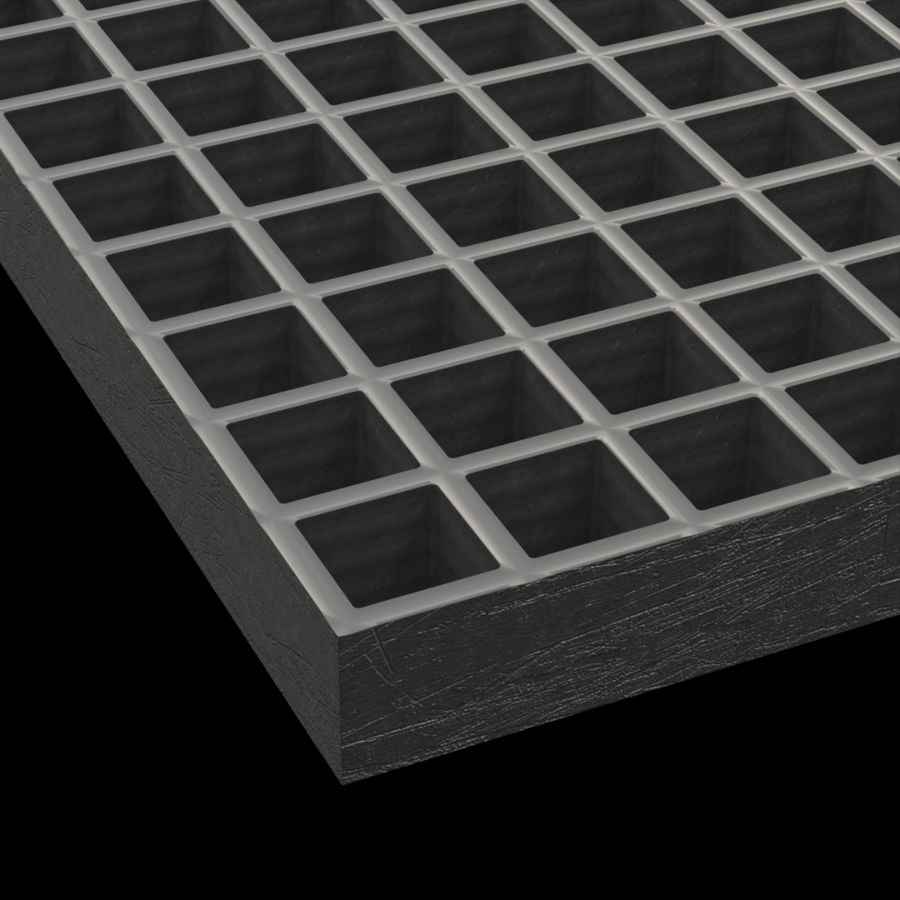

thin perforated metal sheet

Thin perforated metal sheets have emerged as a versatile and essential component across various industries, reflecting both artistic innovation and functional practicality. These sheets are characterized by their precise and strategic perforations, offering unique solutions for a myriad of applications. Delving into their experiential benefits, professional insights, authority in utilization, and established credibility unveils the robust impact thin perforated metal sheets have in advancing industrial and artistic endeavors.

Trustworthiness is another pillar reinforced by the consistent quality and reliability of thin perforated metal sheets. Leading manufacturers adhere to rigorous testing procedures, ensuring that each sheet not only fulfills but often exceeds regulatory compliances. The trust built through decades of performance reliability has led to these materials being specified in prestigious projects worldwide, from world-famous architectural landmarks to innovative technological devices. Committing to sustainable practices, many producers now prioritize environmentally friendly processes in the fabrication of thin perforated metal sheets. The use of recyclable materials and energy-efficient production techniques further emphasize the sheets’ role in supporting eco-friendly initiatives. This sustainable approach enhances the perception of these sheets as not only a tool for innovation and creation but also a responsible choice for modern construction and manufacturing needs. In conclusion, thin perforated metal sheets are a testament to the blend of art, science, and functionality. Their application across industries not only demonstrates versatility but also highlights the critical importance of expertise, authority, and trust in materials that shape the future. This fascinating interplay of light, material, and space continues to inspire, offering endless possibilities for innovation and expression. As industries evolve, so too will the innovative uses of these essential, yet meticulously crafted components.

Trustworthiness is another pillar reinforced by the consistent quality and reliability of thin perforated metal sheets. Leading manufacturers adhere to rigorous testing procedures, ensuring that each sheet not only fulfills but often exceeds regulatory compliances. The trust built through decades of performance reliability has led to these materials being specified in prestigious projects worldwide, from world-famous architectural landmarks to innovative technological devices. Committing to sustainable practices, many producers now prioritize environmentally friendly processes in the fabrication of thin perforated metal sheets. The use of recyclable materials and energy-efficient production techniques further emphasize the sheets’ role in supporting eco-friendly initiatives. This sustainable approach enhances the perception of these sheets as not only a tool for innovation and creation but also a responsible choice for modern construction and manufacturing needs. In conclusion, thin perforated metal sheets are a testament to the blend of art, science, and functionality. Their application across industries not only demonstrates versatility but also highlights the critical importance of expertise, authority, and trust in materials that shape the future. This fascinating interplay of light, material, and space continues to inspire, offering endless possibilities for innovation and expression. As industries evolve, so too will the innovative uses of these essential, yet meticulously crafted components.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP