1 月 . 26, 2025 08:47

Back to list

Hexagonal Mesh Wire Fencing China Suppliers 0.7 - 145 mm Baby Chicken Mesh Wires Used for 1X2 Welded Wire Fence

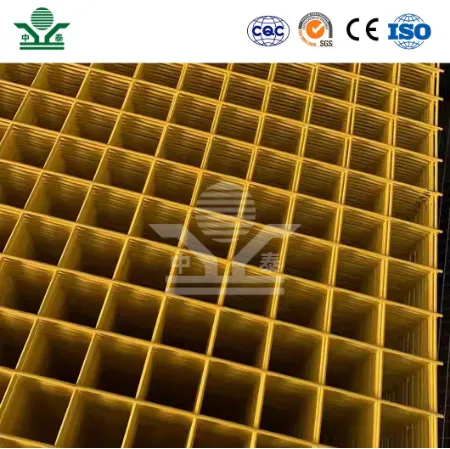

Swaged grating, the unsung hero of industrial flooring solutions, delivers a robust, reliable, and resilient framework for a variety of applications. For the uninitiated, swaged grating is a grid-like structure crafted from a union of longitudinal bars and cross bars, forged under immense pressure to ensure a sturdy and seamless integration. This unique construction method grants the grating optimal durability and longevity, making it a staple in industries such as construction, mining, oil and gas, and transportation.

The authority of swaged grating is not just industrial writ large; it extends into regulatory domains as well. Major safety and construction standards, both national and international, acknowledge and sometimes specify swaged grating as an ideal material for specific applications. This authority lends significant credibility to its use, offering peace of mind to decision-makers looking to adhere to best practices and regulatory requirements alike. Trustworthiness in a product is woven from tangible results and reliable performance over time. Swaged grating's continuous evolution and adaptation to new challenges speak volumes about its trustworthiness. Customers repeatedly choosing swaged grating cite not only the pragmatic benefits—such as ease of installation and maintenance—but also the assurance it offers in extreme conditions and intensive uses. Such trust is forged through consistent, positive outcomes and the relentless pursuit of quality. In summary, swaged grating proves itself as an indispensable asset across myriad industries. It encapsulates a blend of experience-driven design, expert craftsmanship, authoritative endorsement, and steadfast trustworthiness. Results from numerous case studies and client testimonials perpetuate a narrative of reliability and performance not just claimed but genuinely experienced. Thus, swaged gratings stand unrivaled as both a practical and strategic choice for floor grating requirements, fortifying infrastructure today while paving the way for innovation tomorrow.

The authority of swaged grating is not just industrial writ large; it extends into regulatory domains as well. Major safety and construction standards, both national and international, acknowledge and sometimes specify swaged grating as an ideal material for specific applications. This authority lends significant credibility to its use, offering peace of mind to decision-makers looking to adhere to best practices and regulatory requirements alike. Trustworthiness in a product is woven from tangible results and reliable performance over time. Swaged grating's continuous evolution and adaptation to new challenges speak volumes about its trustworthiness. Customers repeatedly choosing swaged grating cite not only the pragmatic benefits—such as ease of installation and maintenance—but also the assurance it offers in extreme conditions and intensive uses. Such trust is forged through consistent, positive outcomes and the relentless pursuit of quality. In summary, swaged grating proves itself as an indispensable asset across myriad industries. It encapsulates a blend of experience-driven design, expert craftsmanship, authoritative endorsement, and steadfast trustworthiness. Results from numerous case studies and client testimonials perpetuate a narrative of reliability and performance not just claimed but genuinely experienced. Thus, swaged gratings stand unrivaled as both a practical and strategic choice for floor grating requirements, fortifying infrastructure today while paving the way for innovation tomorrow.

Latest news

-

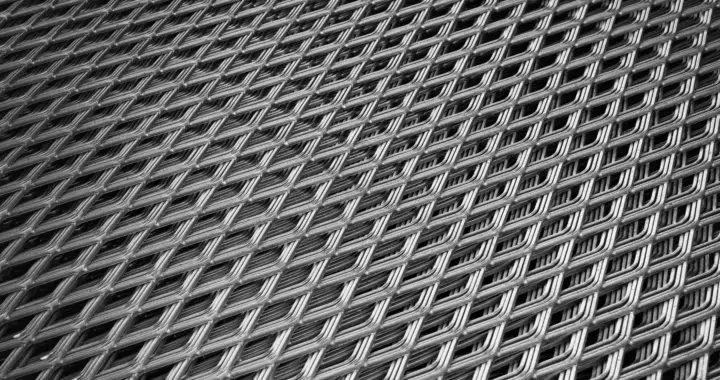

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP