1 月 . 22, 2025 04:09

Back to list

Australia Temporary Fence

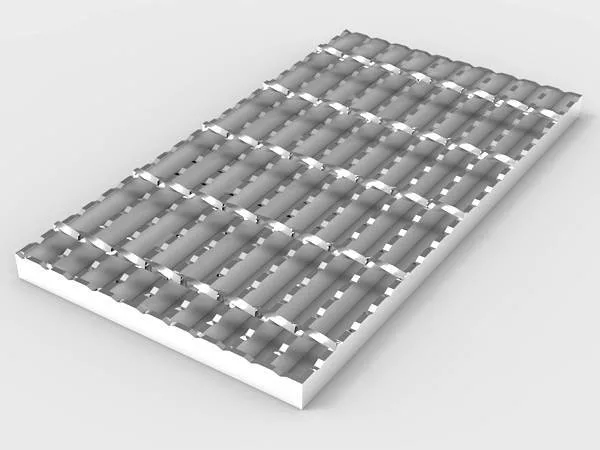

Steel metal grating is an indispensable material in a wide range of industrial and commercial applications, recognized for its robustness, durability, and unparalleled versatility. With decades of proven efficiency, metal grating often forms the backbone of architectural frameworks, industrial platforms, walkways, and safety barriers. This article explores the multifaceted benefits of steel metal grating and why it remains the preferred choice for professionals seeking reliability and excellence in their projects.

Trustworthiness is inherent in the narrative of steel metal grating's extensive application history. Over the years, it has become synonymous with safety and reliability in domains such as oil and gas, mining, chemical facilities, and transportation networks. Manufacturers consistently invest in technological advancements to enhance the grating’s resistance to environmental stresses and ensure longevity. Clients can rely on trusted suppliers who maintain transparency in material sourcing and production processes, upholding environmental and ethical standards alongside technological excellence. Incorporating steel metal grating into your next project promises innovative solutions for complex structural needs. Its modular design allows for customization and expansion, effectively accommodating future growth without significant structural overhauls. Whether employed in urban construction or remote industrial setups, steel grating adapts seamlessly, offering a balance of strength, weight, and cost-efficiency. To encapsulate, steel metal grating is an unparalleled product that combines experiential reliability, expert design, authoritative approval, and trustworthy manufacture. Its standing in industrial and commercial construction showcases its absolute value, providing a foundation of safety, efficiency, and economic feasibility. Those investing in steel grating benefit from tried and tested performance, ensuring project success from inception to fulfillment. For anyone desiring sustainable and resilient infrastructure components, steel metal grating remains an indispensable ally in building the future with confidence and precision.

Trustworthiness is inherent in the narrative of steel metal grating's extensive application history. Over the years, it has become synonymous with safety and reliability in domains such as oil and gas, mining, chemical facilities, and transportation networks. Manufacturers consistently invest in technological advancements to enhance the grating’s resistance to environmental stresses and ensure longevity. Clients can rely on trusted suppliers who maintain transparency in material sourcing and production processes, upholding environmental and ethical standards alongside technological excellence. Incorporating steel metal grating into your next project promises innovative solutions for complex structural needs. Its modular design allows for customization and expansion, effectively accommodating future growth without significant structural overhauls. Whether employed in urban construction or remote industrial setups, steel grating adapts seamlessly, offering a balance of strength, weight, and cost-efficiency. To encapsulate, steel metal grating is an unparalleled product that combines experiential reliability, expert design, authoritative approval, and trustworthy manufacture. Its standing in industrial and commercial construction showcases its absolute value, providing a foundation of safety, efficiency, and economic feasibility. Those investing in steel grating benefit from tried and tested performance, ensuring project success from inception to fulfillment. For anyone desiring sustainable and resilient infrastructure components, steel metal grating remains an indispensable ally in building the future with confidence and precision.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP