1 月 . 26, 2025 06:25

Back to list

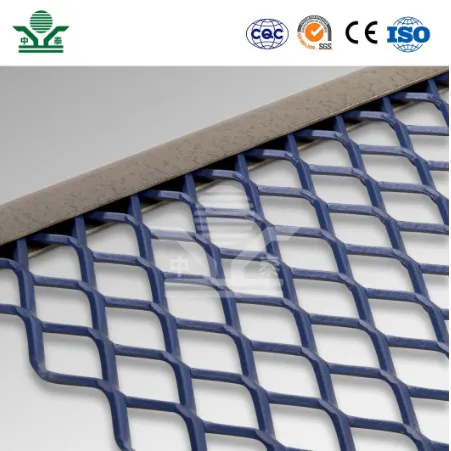

steel grating galvanized

Steel grating galvanized has gained significant attention across various industries due to its impeccable performance and longevity. Among the vast array of construction materials, galvanized steel grating stands out as a reliable solution for creating sturdy floors, walkways, and platforms. Professionals and industry experts consistently highlight the product’s strength, safety, and cost-effectiveness, making it a preferred choice for both small and large-scale projects.

The authoritative voice of leading manufacturers and civil engineers cannot be overstated when it comes to steel grating galvanized. They underscore its versatility, with applications ranging from pedestrian walkways and service platforms to trench covers and security enhancements. Notably, the material's non-slip surface is a critical safety feature that reduces the risk of workplace accidents, a factor that underscores its importance in employee safety protocols. Technical specifications provided by top-tier manufacturers offer detailed insights into load-bearing capacities and design options, empowering engineers to make informed decisions tailored to specific project needs. Trustworthiness emerges from decades of successful implementations worldwide and endorsements from various certification bodies. Compliance with international standards such as ISO and ASTM ensures that galvanized steel grating meets rigorous quality and performance benchmarks. Customers can rely on this certification when opting for a product that promises consistency and safety. Furthermore, reviews and feedback from global clients often point to the product’s reliability, which enhances trust among potential buyers. Overall, the demand for steel grating galvanized continues to rise, primarily driven by its superior attributes and positive evaluations. As industries evolve and the demand for high-quality materials becomes more pressing, investing in such durable solutions not only optimizes operations but also secures long-term benefits. Hence, the expertise, authority, and real-world experience conveyed through this discussion offer a comprehensive understanding of why this material is a cornerstone in modern construction and infrastructure projects.

The authoritative voice of leading manufacturers and civil engineers cannot be overstated when it comes to steel grating galvanized. They underscore its versatility, with applications ranging from pedestrian walkways and service platforms to trench covers and security enhancements. Notably, the material's non-slip surface is a critical safety feature that reduces the risk of workplace accidents, a factor that underscores its importance in employee safety protocols. Technical specifications provided by top-tier manufacturers offer detailed insights into load-bearing capacities and design options, empowering engineers to make informed decisions tailored to specific project needs. Trustworthiness emerges from decades of successful implementations worldwide and endorsements from various certification bodies. Compliance with international standards such as ISO and ASTM ensures that galvanized steel grating meets rigorous quality and performance benchmarks. Customers can rely on this certification when opting for a product that promises consistency and safety. Furthermore, reviews and feedback from global clients often point to the product’s reliability, which enhances trust among potential buyers. Overall, the demand for steel grating galvanized continues to rise, primarily driven by its superior attributes and positive evaluations. As industries evolve and the demand for high-quality materials becomes more pressing, investing in such durable solutions not only optimizes operations but also secures long-term benefits. Hence, the expertise, authority, and real-world experience conveyed through this discussion offer a comprehensive understanding of why this material is a cornerstone in modern construction and infrastructure projects.

Next:

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP