Understanding the Cost of Steel Grating per Square Foot

When it comes to industrial applications and construction, steel grating is a popular choice for flooring, walkways, and stair treads due to its strength, durability, and ability to allow for drainage and ventilation. However, one critical factor that engineers, contractors, and project managers need to consider is the cost of steel grating, specifically the cost per square foot. This article will delve into the various factors that affect the pricing of steel grating, methods of estimating costs, and tips for budgeting your project effectively.

Factors Influencing Cost

1. Material Quality The type of steel used in manufacturing the grating significantly influences the cost. Carbon steel is generally less expensive than stainless steel, which, while more expensive, offers greater corrosion resistance and longevity in harsh environments. For specific applications, such as food processing or marine environments, the extra cost of stainless steel may be well worth it.

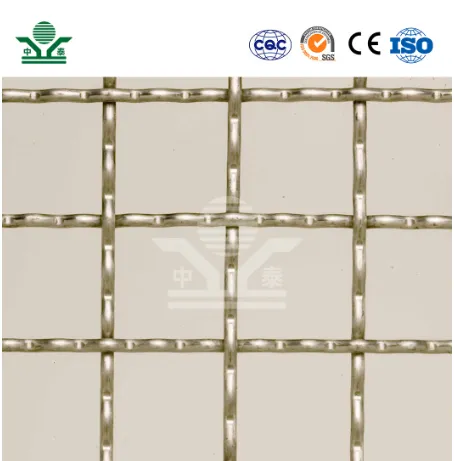

2. Grating Type There are several types of steel grating, including welded, swage-locked, and press-locked. Welded grating is typically the most economical and is widely used for general purposes. Swage-locked grating, which is often used in heavier-duty applications, may have higher costs due to its manufacturing processes. The choice of type will dramatically affect your cost per square foot.

3. Bar Size and Spacing The size and spacing of the bars used in the grating also impact the overall cost. Larger bars may provide greater strength and load capacity but will increase the material cost. Conversely, closer bar spacing may ensure safety underfoot but can also drive up expenses. Selecting the right bar size involves balancing safety, cost, and intended use.

4. Finish and Coatings Steel grating can be treated with various coatings, such as galvanized or painted finishes, which protect against corrosion and improve the lifespan of the grating. These additional treatments can raise the cost per square foot but are often necessary for specific environments where exposure to moisture or chemicals is common.

5. Quantity and Bulk Discounts As with many materials, purchasing in larger quantities often leads to discounts. If you have a large project, consider ordering to scale, as many suppliers offer price breaks when you buy in bulk, which can significantly lower your cost per square foot.

Estimating Costs

To get a precise estimate of the steel grating costs for your project, it's essential to measure the area you intend to cover. Here's a simple approach to calculating costs

steel grating cost per square foot

1. Measure the Area Calculate the total square footage of the area where the grating will be installed. This will determine how much material you need.

2. Request Quotes Contact multiple suppliers for quotes on your desired type of grating. Be sure to specify the material, type, bar size and spacing, and any coatings you need.

3. Calculate the Total Cost Multiply the price per square foot by the total square footage. Don’t forget to include additional costs such as shipping and installation if applicable.

Budgeting Tips

1. Plan Ahead Understand the specific needs of your project and confirm that the type of grating selected is appropriate for its application. This will help avoid costly last-minute changes.

2. Consider Lifecycle Costs While it may be tempting to go with the cheapest option, consider the long-term costs associated with maintenance and replacement. Investing in higher-quality grating may save you money in the long run.

3. Utilize Resources Take advantage of resources like online calculators or cost estimators that can provide quick estimates and comparisons across various types of grating.

Conclusion

In conclusion, understanding the cost of steel grating per square foot involves multiple factors, from material choices to the specific application requirements. By taking the time to analyze these factors, request quotes, and budget appropriately, you can ensure that your project is not only cost-effective but also meets the necessary safety and performance standards. Investing the effort upfront will pay dividends in durability, performance, and savings over time.

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.