1 月 . 19, 2025 01:50

Back to list

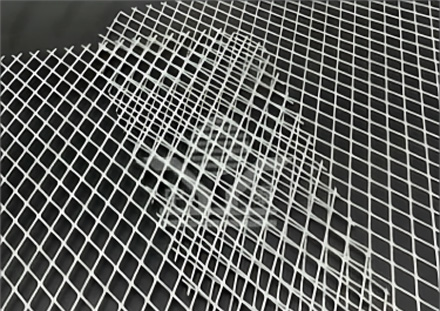

steel expanded mesh sheets

Steel expanded mesh sheets have emerged as a versatile and durable solution in a multitude of applications, from industrial to architectural domains. Their unique structure not only provides strength and resilience but also offers aesthetic appeal, making them a popular choice among designers, engineers, and architects. Understanding the intricacies of these sheets can significantly enhance one's ability to make informed decisions when selecting materials for specific projects.

Authoritativeness in the context of steel expanded mesh sheets comes from industry standards and endorsements by trusted organizations. Globally recognized standards ensure the quality and consistency of these products, providing a benchmark for manufacturers and assurance for customers. Organizations such as ASTM (American Society for Testing and Materials) provide guidelines that specify the mechanical properties, such as tensile and yield strength, and chemical composition tolerances these mesh sheets must meet. Such standards are critical as they assure stakeholders of the material's suitability for use in demanding environments, where safety and performance cannot be compromised. Trustworthiness in the use and application of steel expanded mesh sheets is supported by numerous case studies and long-term field data demonstrating their reliability and adaptability. Companies with a proven track record of manufacturing quality mesh sheets offer certifications and warranties that provide peace of mind for buyers. Additionally, the traceability of materials throughout the supply chain ensures that each sheet can be sourced back to its origin, verifying its compliance with industry standards and regulations. Collaborative projects with reputed construction firms further bolster their credibility, as these entities depend on consistent quality and performance when integrating mesh sheets into their designs. Overall, the inclusion of steel expanded mesh sheets in a project brings a plethora of benefits facilitated by their structural soundness, aesthetic adaptability, and potential cost savings. Their robustness and versatility make them an ideal choice for modern construction and design challenges. Through the combined lens of experience, expertise, authoritativeness, and trustworthiness, these materials not only meet but often exceed expectations, proving to be an invaluable asset in the toolkit of innovative construction and design professionals.

Authoritativeness in the context of steel expanded mesh sheets comes from industry standards and endorsements by trusted organizations. Globally recognized standards ensure the quality and consistency of these products, providing a benchmark for manufacturers and assurance for customers. Organizations such as ASTM (American Society for Testing and Materials) provide guidelines that specify the mechanical properties, such as tensile and yield strength, and chemical composition tolerances these mesh sheets must meet. Such standards are critical as they assure stakeholders of the material's suitability for use in demanding environments, where safety and performance cannot be compromised. Trustworthiness in the use and application of steel expanded mesh sheets is supported by numerous case studies and long-term field data demonstrating their reliability and adaptability. Companies with a proven track record of manufacturing quality mesh sheets offer certifications and warranties that provide peace of mind for buyers. Additionally, the traceability of materials throughout the supply chain ensures that each sheet can be sourced back to its origin, verifying its compliance with industry standards and regulations. Collaborative projects with reputed construction firms further bolster their credibility, as these entities depend on consistent quality and performance when integrating mesh sheets into their designs. Overall, the inclusion of steel expanded mesh sheets in a project brings a plethora of benefits facilitated by their structural soundness, aesthetic adaptability, and potential cost savings. Their robustness and versatility make them an ideal choice for modern construction and design challenges. Through the combined lens of experience, expertise, authoritativeness, and trustworthiness, these materials not only meet but often exceed expectations, proving to be an invaluable asset in the toolkit of innovative construction and design professionals.

Latest news

-

The Best Metal Mesh Solutions: Expanded Aluminum Metal vs. Expanded Stainless Steel Metal

NewsSep.10,2024

-

Round Perforated Sheets vs. Hexagonal Perforated Sheets vs. Embossed Perforated Sheet Metal

NewsSep.10,2024

-

Perforated Metal Sheets

NewsSep.10,2024

-

Experience The Excellence Of Stainless Steel Grating

NewsSep.10,2024

-

Discover the Versatility Of Metal Mesh Expanded Forming Machines

NewsSep.10,2024

-

Discover The Advantages Of Steel Grating For Sale

NewsSep.10,2024

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP